8-25

62-11039

c. Adding Oil To Service Replacement Compressor

NOTE

1. Service replacement compressors are

shipped without oil.

2. When first adding oil to the compressor,

add only 6.3 pints (3 liters) to the

compressor. Run the unit for 20 minutes in

cooling mode. Check the oil level in the

compressor sight glass. Add oil as

necessary. This procedure is designed to

compensate for excess oil that may have

migrated with refrigerant to other parts of

the system during unit operation.

d. Removing oil from the compressor

1. If the oil level recorded in step a.3. is above one-

eighth level of the capacity of the sight glass, oil must

be removed from the compressor.

2. Close (frontseat) suction service valve and pump

unit down to 2 to 4 psig (0.1 to 0.3 bar). Frontseat dis-

charge service valve and slowly bleed remaining re-

frigerant.

3. Remove the oil drain plug on the bottom plate of the

compressor and drain the proper amount of oil from

the compressor to obtain the correct level (maximum

is one-eight level of the sight glass). Replace the

plug securely back into the compressor.

DO NOT

FORGET TO OPEN SUCTION AND DISCHARGE

SERVICE VALVES.

4. Repeat step a.3 to ensure proper oil level.

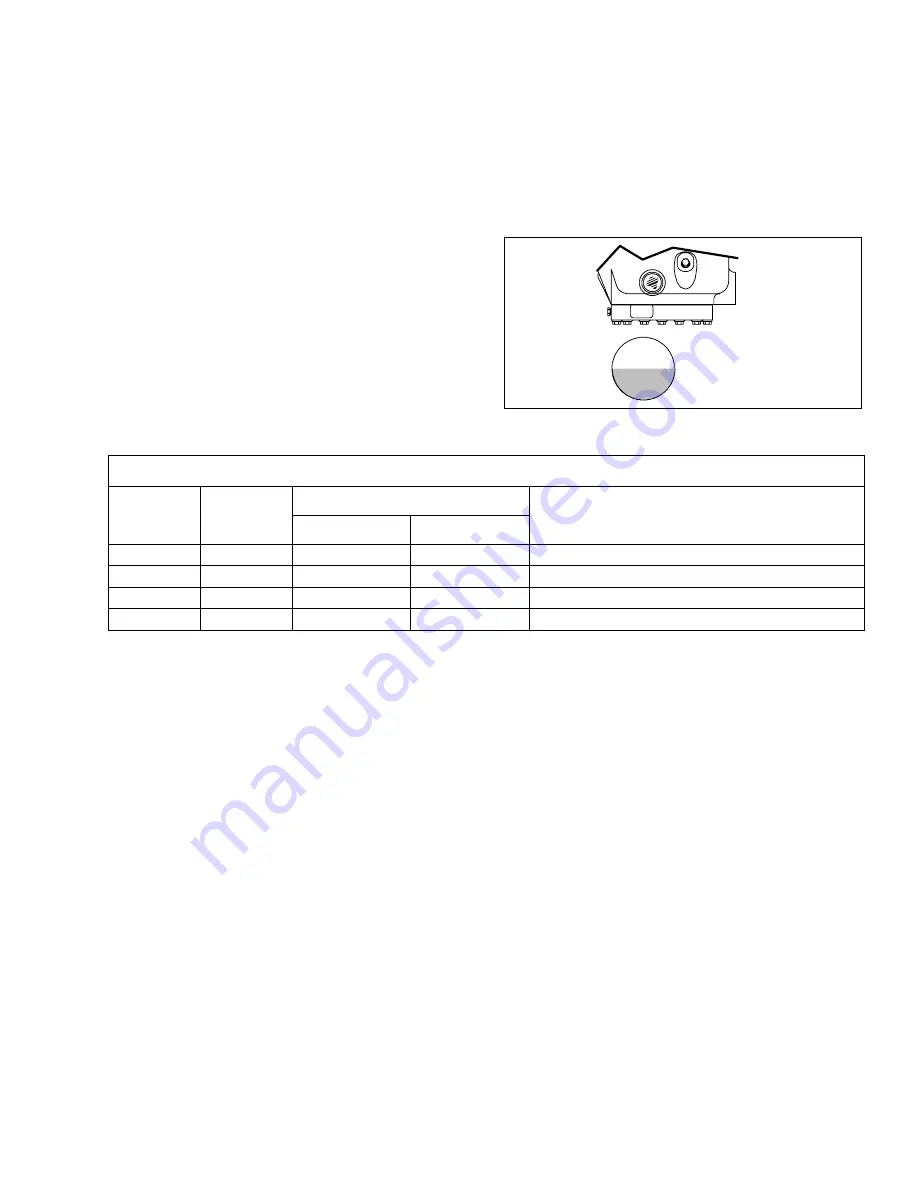

-- Maximum

-- Minimum

Figure 8--26. Oil Level in Sight Glass

Table 8-3 Compressor Torque Values

SIZE

TORQUE RANGE

SIZE

DIAMETER THREADS

TORQUE RANGE

USAGE

DIAMETER

(INCHES)

THREADS

PER INCH

FT LB

MKG

USAGE

(INCHES)

PER INCH

FT-LB

MKG

1/4

28

12 -- 16

1.66 -- 2.21

Unloader Valve

5/16

18

20 -- 30

2.77 -- 4.15

Discharge Valve

3/8

16

40 -- 50

5.53 -- 6.92

Cylinder Head

1/2

13

65--70

9.0--9.7

Suction Valve

8.15 COMPRESSOR UNLOADER VALVE

The compressor unloaders (located on the compressor

cylinder heads) are controlled by the Advance

Microprocessor. (Refer to Section 2.3.3)

a. Manual Checkout procedure

1. Initiate Pretrip.

2. Connect manifold gauges to the compressor suction

and discharge service valves and start unit in cooling

with the trailer temperature at least 5

_

F (2.8

_

C)

above set point and the compressor will be fully

loaded (both unloader coils are de-energized). Note

suction pressure.

3. Unplug both unloader coils.

4. Using fused jumper wires energize front unloader.

Note discharge and suction pressures. A rise of

approximately 3 psig (0.2 Bar) will be noted on the

suction pressure gauge. Discharge pressure should

drop approximately 5 to 15 psig (0.4 to 1.0 Bar).

5. Disconnect UL1 and note pressures. Suction pres-

sure should drop and discharge pressure should rise

by same amount as in step 4. above.

6. Repeat steps 3 & 4 for UL2 (rear unloader). At the

end of the test, plug both unloaders back in.

NOTE

If either unloader coil energizes and the suction

and discharge pressures do not change, the un-

loader assembly must be checked.

b. Replacing solenoid valve internal parts (see

Figure 8--27)

1. Put gauges on the compressor.

2. Pump down the compressor to 0--5 psig

(0 to 0.3 Bar). Frontseat both service valves to isolate

compressor.

3. Equalize compressor high and low side pressures.

4. Recover refrigerant remaining in compressor.

5. Remove coil retainer and coil.

6. Remove enclosing tube collar (Item 4, Figure 8--27)

using installation/removal tool supplied with repair kit

(item 3).

7. Check plunger for restriction due to: (a) Corroded or

worn parts; (b) Foreign material lodged in valve; (c) Bent

or dented enclosing tube.

8. Install new parts. Do not overtighten enclosing tube

assembly. Torque to a value of 100 inch pounds (1.15

kmg).

9. Remove supplied installation/removal tool. Install

coil, voltage plate, and retainer.

10. Evacuate and dehydrate the compressor.

Summary of Contents for VECTOR 1800 MT

Page 1: ......

Page 2: ...OPERATION SERVICE MANUAL for VECTOR 1800 MT Trailer Multi Temp Refrigeration Units ...

Page 19: ...1 5 62 11039 1 3 SAFETY DECALS ...

Page 20: ...1 6 62 11039 62 03958 00 Heat Warning 62 03957 01 High Voltage 62 60280 00 Standby Safety ...

Page 21: ...1 7 62 11039 ...

Page 303: ...10 1 62 11039 ...

Page 310: ...10 8 62 11039 BASED ON ENGINEERING SCHEMATIC 62 60926 REV G NEXT SHT ...

Page 311: ...10 9 62 11039 FROM PREVIOUS SHT ...