47

ALARM EQUIPMENT PRIORITY

The ComfortVIEW software uses the equipment priority value

when sorting alarms by level. The purpose of the equipment

priority value is to determine the order in which to sort alarms

that have the same level. A priority of 0 is the highest and

would appear first when sorted. A priority of 7 would appear

last when sorted. For example, if two chillers send out identical

alarms, the chiller with the higher priority would be listed first.

The default is 4. This variable can only be changed when using

the ComfortVIEW software, or Network Service Tool. This

variable cannot be changed with the Carrier Controller display.

To configure this option with the Network Service Tool, navi-

gate to point

EQP_TYP

in table

ALARMDEF

.

COMMUNICATION FAILURE RETRY TIME

This variable specifies the amount of time that will be allowed

to elapse between alarm retries. Retries occur when an alarm is

not acknowledged by a network alarm acknowledger, which

may use either ComfortVIEW software or TeLink. If acknowl-

edgment is not received, the alarm will be re-transmitted after

the number of minutes specified in this decision. This variable

can only be changed when using the ComfortVIEW software,

or Network Service Tool. This variable cannot be changed with

the Carrier Controller display. To configure this option with the

Network Service Tool, navigate to point

RETRY_TM

in table

ALARMDEF

.

RE-ALARM TIME

This variable specifies the amount of time that will be allowed

to elapse between re-alarms. A re-alarm occurs when the con-

ditions that caused the initial alarm continue to persist for the

number of minutes specified in this decision. Re-alarming will

continue to occur at the specified interval until the condition

causing the alarm is corrected. This variable can only be

changed when using the ComfortVIEW software, or Network

Service Tool. This variable cannot be changed with the Carrier

Controller display. To configure this option with the Network

Service Tool, navigate to point

RE_ALARM

in table

ALARMDEF

.

ALARM SYSTEM NAME

This variable specifies the system element name that will ap-

pear in the alarms generated by the unit control. The name can

be up to 8 alphanumeric characters in length. This variable can

only be changed when using the ComfortVIEW™ software or

Network Service Tool. This variable cannot be changed with

the Carrier Controller display. To configure this option with the

Network Service Tool, navigate to point

ALRM_NAM

in ta-

ble

ALARMDEF

.

Daylight Savings Time Configuration

The 30XV chiller with Greenspeed

®

Intelligence control con-

tains software which can automatically correct for daylight sav-

ings time. This software is accessible from the Carrier Controller

display, ComfortVIEW software, or Network Service Tool.

To enable this feature, Daylight Savings Select must be set to

1. The start of daylight saving must be configured by setting

the Month, Day of Week, and Week of Month. The end for

Daylight Saving must also be configured. To configure this op-

tion with the Carrier Controller display, see Table 30.

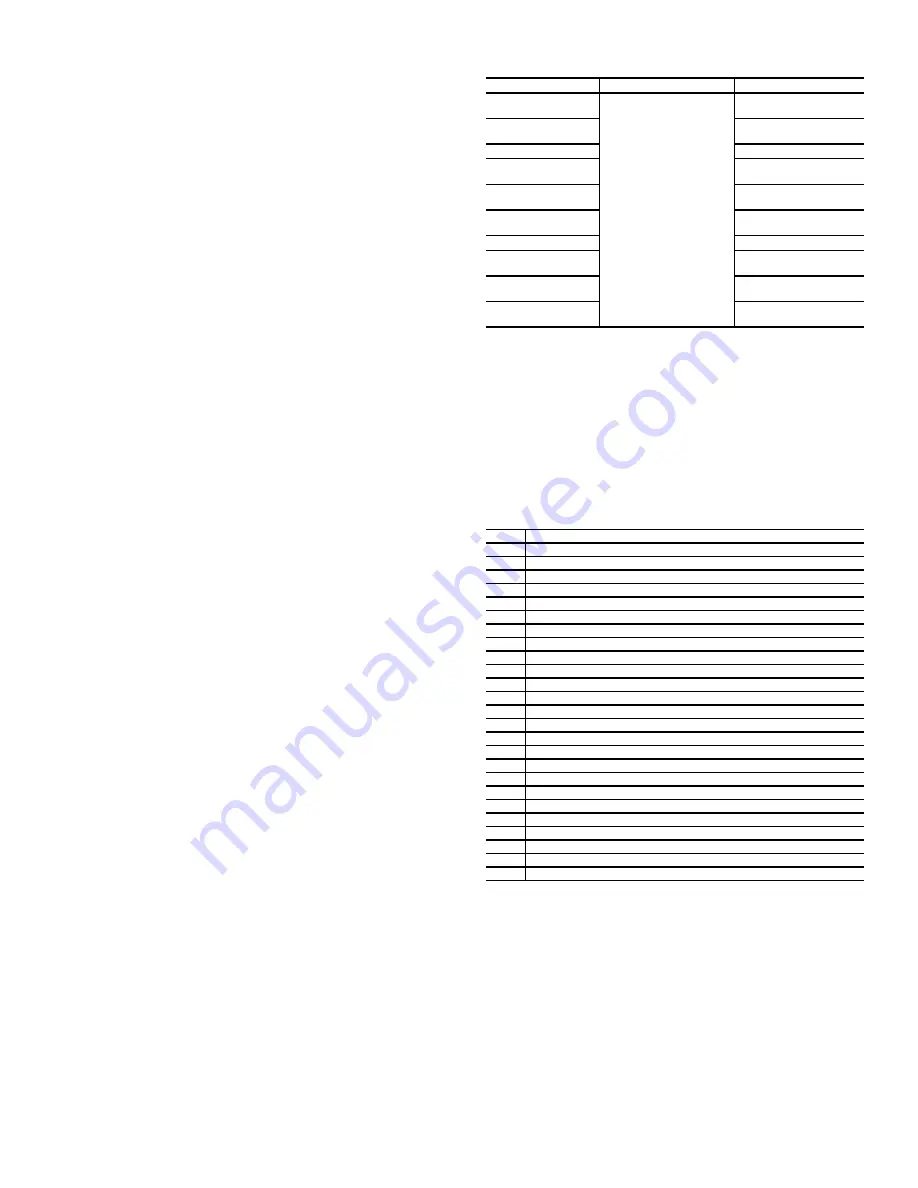

Table 30 — Daylight Savings Time Configuration

Capacity Control Overrides

The following capacity control overrides (

Main Menu

Maintenance Menu

Capacity Control

Override Capaci-

ty Nb A, B

) will modify the normal operation routine. If any of

the override conditions listed below is satisfied, the override

will determine the capacity change instead of the normal con-

trol. Overrides are listed by priority order and are often linked

to unit operating modes. See Table 31 for a list of capacity con-

trol overrides. See the Operating Modes section on page 56 for

more information regarding operating modes.

Table 31 — Capacity Control Overrides

Override #2: Low Suction Pressure

This override is activated when the Expansion Valve (EXV) is

not in DSH (discharge superheat) mode and the Saturated Suc-

tion Temperature (SST) goes below 13.25°F (–10.4°C) for wa-

ter or below (13.25°F – (34°F – Brine Freeze Setpoint)) for

units configured with brine. The controller at this point starts to

unload the unit until the SST exceeds 34°F (1.1°C).

Override #6: EWT < Control Point

This override stops the compressors without alarms.

Override #7: Ramp Loading

No capacity increase will be made if the unit is configured for

ramp loading and the rate of change of the leaving water is

greater than Ramp Loading Rate.

DISPLAY NAME

PATH

VALUE

Activate

Main Menu

Configuration Menu

Broadcast Menu

Brocasts

1 or 2

Default = 2

Daylight

Savings Select

Enable

Default = Disable

Entering

Month

Enter Starting Month for

Daylight Saving

Day of Week

(1=Monday)

Enter the Day of the Week

Daylight Saving Starts

Week of Month

Enter Week of the Month

Daylight Saving Starts

Leaving

Month

Enter Ending Month for

Daylight Saving

Day of Week

(1=Monday)

Enter the Day of the Week

Daylight Saving ends

Week of Month

Enter Week of the Month

Daylight Saving ends

NO.

DESCRIPTION

0

Normal Operation

2

Low Suction Pressure

6

EWT < control point

7

Ramp Loading

9

Demand Limit Reached

10

Flow switch is open

11

Customer Interlock is closed

12

Flow Available Delay

14

Low LWT

15

Compressor Disabled

16

High Discharge Pressure

23

Low SP

25

Oil Recovery

34

Low SST

53

ON-OFF-ON Delay

56

Evaporator Heater Isolation Valve Opening Delay

59

Low Oil Level

62

High Compressor Motor Temperature

66

High Discharge Gas Temperature

67

DGT Off Protection

70

Low Refrigerant Protection

71

Low Refrigerant Protection

77

Oil Pressure at Start

78

Bad VFD Spd At Start

91

Demand Limit

Summary of Contents for AquaForce 30XV140

Page 79: ...79 Fig 76 VFD Communication Wiring Compressor A B Fan VFD A1 A2 B1 B2...

Page 228: ...228 Fig 90 30XV Typical Field Wiring Schematic cont...

Page 229: ...229 Fig 91 30XV Standard Tier 140 275 All Voltages Power Schematic NOTE See Legend on page 226...

Page 230: ...230 Fig 92 30XV Standard Tier 300 325 All Voltages Power Schematic NOTE See Legend on page 226...

Page 240: ...240 Fig 99 30XV Communication Wiring...

Page 241: ...241 Fig 100 30XV 115V Control Wiring All Tonnages All Voltages...

Page 242: ...242 Fig 101 30XV 24V Control Wiring 30XV140 325 All Voltages...

Page 243: ...243 Fig 101 30XV 24V Control Wiring 30XV140 325 All Voltages cont...

Page 244: ...244 Fig 102 30XV 24V Control Wiring 30XV350 500 All Voltages...

Page 245: ...245 Fig 102 30XV 24V Control Wiring 30XV350 500 All Voltages cont...

Page 246: ...246 Fig 103 Component Arrangement Diagram for 30XV140 325...

Page 247: ...247 Fig 103 Component Arrangement Diagram for 30XV140 325 cont...

Page 248: ...248 Fig 104 Component Arrangement Diagram for 30XV350 500...

Page 337: ...337 APPENDIX J FACTORY SUPPLIED PUMPS cont Fig L System Information...

Page 338: ...338 APPENDIX J FACTORY SUPPLIED PUMPS cont Fig M Unit and Language Settings...

Page 341: ...341 APPENDIX J FACTORY SUPPLIED PUMPS cont Fig P Data Input 2...

Page 342: ...342 APPENDIX J FACTORY SUPPLIED PUMPS cont Fig Q Data Input 3...

Page 347: ...347 APPENDIX J FACTORY SUPPLIED PUMPS cont Fig U Pump Wiring Diagram...