64

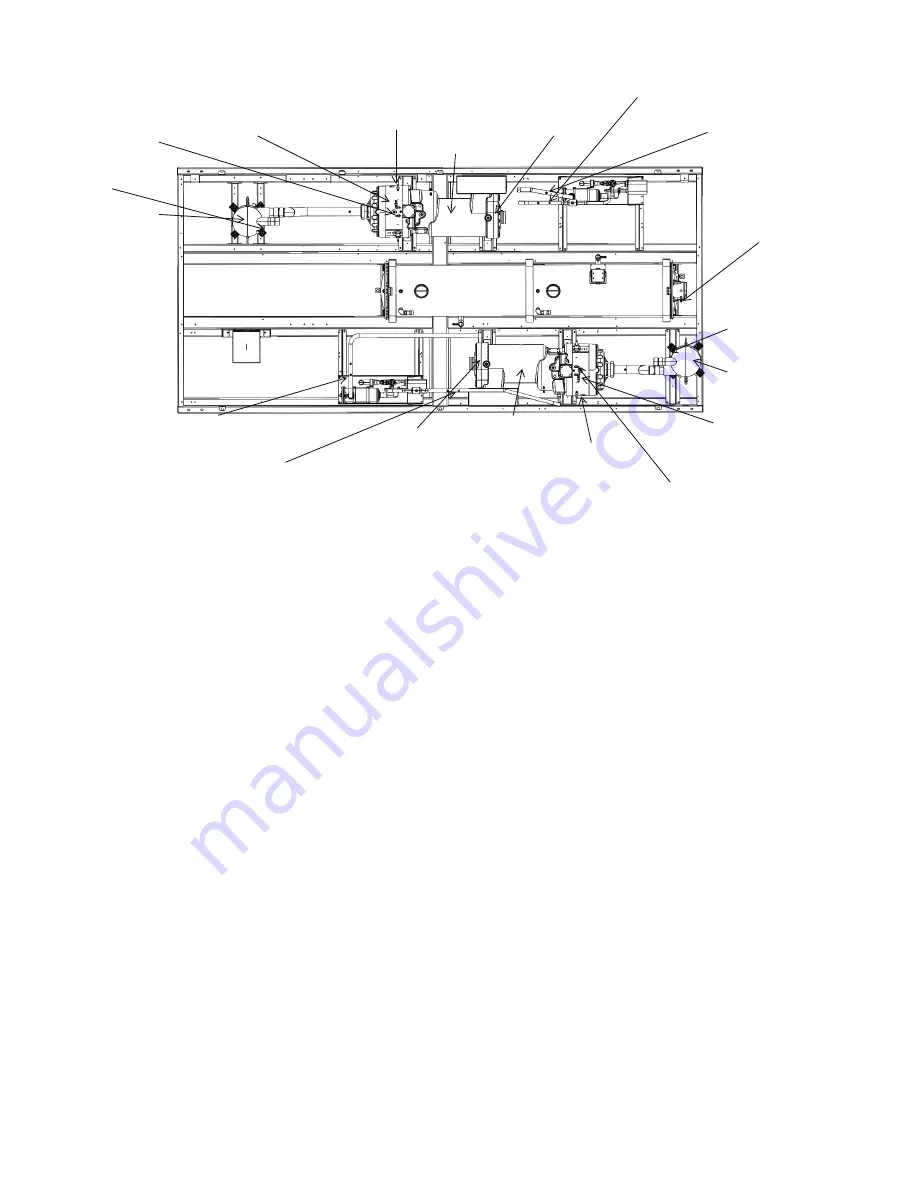

Fig. 58 — Transducer and Switch Locations

SERVICE

Economizer Assembly

Each circuit on the unit has an economizer assembly, which in-

cludes a brazed plate heat exchanger, EXVs, and other compo-

nents. See Fig. 59.

Electronic Expansion Valve

See Fig. 60 for a cutaway view of the EXV. High-pressure liq-

uid refrigerant enters the valve through the top. As refrigerant

passes through the orifice, pressure drops and refrigerant

changes to a 2-phase condition (liquid and vapor). The elec-

tronic expansion valve operates through electronically con-

trolled activation of a stepper motor. The stepper motor stays in

position unless power pulses initiate the two discrete sets of

motor stator windings for rotation in either direction. The di-

rection depends on the phase relationship of the power pulses.

The motor directly operates the spindle, which has rotating

movements that are transformed into linear motion by the

transmission in the cage assembly. The valve cone is a V-port

type which includes a positive shut-off when closed. The large

number of steps and long stroke results in very accurate control

of the refrigerant flow. The stepper motor has either 3810

(main) or 2625 (economizer) steps.

MAIN EXV CONTROL

The main EXV is controlled by the SIOB (J17-STPR1). Each

circuit has thermistors located in the compressor discharge

(DGT), compressor motor cavity (SGT) and liquid line leaving

the condenser (LIQT). Each circuit also has a DPT, SPT, and

LPT. All the pressure readings as measured by the transducers

are converted to saturated temperatures. Liquid pressure trans-

ducer (LPT) is converted to saturated liquid temperature (SLT).

The main control logic for the EXV uses liquid line subcool-

ing, which is the difference between the liquid line saturation

temperature and the liquid line temperature, to control the

position of the EXV. The SIOB module controls the position of

the electronic expansion valve stepper motor to maintain the

subcooling set point. The EXV control logic has several over-

rides, which are also used to control the position of the EXV.

• Normal Mode (SUBCOOL)

• Low Discharge Superheat (DSH)

• Low Suction Pressure (SPMIN)

• Maximum Suction Pressure (SPMAX)

• EXV Start (START)

To view EXV overrides:

Main Menu

Maintenance Menu

EXV Control

or

Main Menu

Maintenance Menu

EXVECO Control

.

Normal Mode (SUBCOOL)

This is the normal mode of operation of the EXV. Based on the

operating condition and loading of the compressor, the control

calculates an optimal subcooling setting to maximize the sys-

tem efficiency. The controls accordingly adjust the EXV open-

ing to meet this calculated subcooling setting. The range of the

subcooling setting can be altered by using the Network Service

Tool in the

Configuration

EXV_CFG

table.

Low Discharge Superheat (DSH)

This mode is disabled for 100 sec after the start of the circuit.

Control enters this mode when DSH is below 12°F (

–

11.1°C).

The control attempts to drive DSH above 15°F (

–

9.4°C) by

closing the EXV. In this mode the setpoint is modified and

driven to a value that supports a higher DSH value upon exit of

the mode. This prevents mode cycling. Mode is exited when

the DSH is greater than 18

°

F (

–

7.8°C) or the average DSH is

within 1.25° (0.7°C) of 15°F (

–

9.4°C) and the subcooling is

above the subcooling setpoint.

SUCTION PRESSURE

TRANSDUCER (SPT A)

OIL SEPARATOR (A)

OIL PRESSURE

TRANSDUCER (OPT A)

ECONOMIZER PRESSURE

TRANSDUCER (EPT A)

LIQUID PRESSURE

TRANSDUCER (LPT A)

EVAPORATOR (B)

COMPRESSOR (B)

DISCHARGE PRESSURE

TRANSDUCER (DPT A)

SUCTION PRESSURE

TRANSDUCER (SPT B)

OIL PRESSURE

TRANSDUCER (OPT B)

ECONOMIZER PRESSURE

TRANSDUCER (EPT B)

LIQUID PRESSURE

TRANSDUCER (LPT B)

DISCHARGE PRESSURE

TRANSDUCER (DPT B)

OIL LEVEL SWITCH

(OIL LS B)

EVAPORATOR (A)

COMPRESSOR (A)

HIGH PRESSURE

SWITCH (HPS B)

HIGH PRESSURE

SWITCH (HPS A)

EVAPORATOR FLOW

SWITCH (CWFS)

OIL SEPARATOR

(B)

OIL LEVEL SWITCH

(OIL LSA)

POWERBOX END

Summary of Contents for AquaForce 30XV140

Page 79: ...79 Fig 76 VFD Communication Wiring Compressor A B Fan VFD A1 A2 B1 B2...

Page 228: ...228 Fig 90 30XV Typical Field Wiring Schematic cont...

Page 229: ...229 Fig 91 30XV Standard Tier 140 275 All Voltages Power Schematic NOTE See Legend on page 226...

Page 230: ...230 Fig 92 30XV Standard Tier 300 325 All Voltages Power Schematic NOTE See Legend on page 226...

Page 240: ...240 Fig 99 30XV Communication Wiring...

Page 241: ...241 Fig 100 30XV 115V Control Wiring All Tonnages All Voltages...

Page 242: ...242 Fig 101 30XV 24V Control Wiring 30XV140 325 All Voltages...

Page 243: ...243 Fig 101 30XV 24V Control Wiring 30XV140 325 All Voltages cont...

Page 244: ...244 Fig 102 30XV 24V Control Wiring 30XV350 500 All Voltages...

Page 245: ...245 Fig 102 30XV 24V Control Wiring 30XV350 500 All Voltages cont...

Page 246: ...246 Fig 103 Component Arrangement Diagram for 30XV140 325...

Page 247: ...247 Fig 103 Component Arrangement Diagram for 30XV140 325 cont...

Page 248: ...248 Fig 104 Component Arrangement Diagram for 30XV350 500...

Page 337: ...337 APPENDIX J FACTORY SUPPLIED PUMPS cont Fig L System Information...

Page 338: ...338 APPENDIX J FACTORY SUPPLIED PUMPS cont Fig M Unit and Language Settings...

Page 341: ...341 APPENDIX J FACTORY SUPPLIED PUMPS cont Fig P Data Input 2...

Page 342: ...342 APPENDIX J FACTORY SUPPLIED PUMPS cont Fig Q Data Input 3...

Page 347: ...347 APPENDIX J FACTORY SUPPLIED PUMPS cont Fig U Pump Wiring Diagram...