COPYRIGHT © 2001 CANON INC.

2000 2000 2000 2000

CANON iR5000i/iR6000i REV.0 JUNE 2001

CHAPTER 2 SEQUENCE OF OPERATIONS

2-14 P

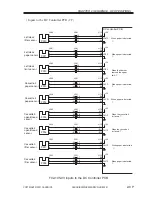

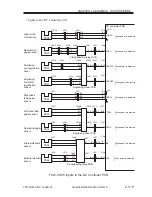

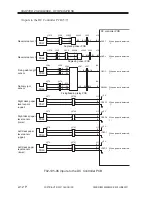

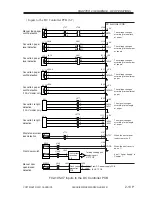

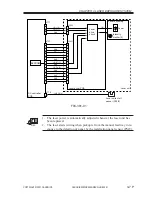

1.5.3 Inputs to the DC Controller PCB

• Inputs to the DC Controller PCB (7/7)

F02-105-08 Inputs to the DC Controller PCB

+24V

DC controller PCB

Developing

assembly

toner sensor

+5V

+12V

Hopper toner

sensor

J103

-B9

-B10

-B11

TEP

When the toner drops

below a specific

volume, '0'.

J153

-3

-2

-1

-5

-6

-7

TS2

+5V

J103

-A7

-A8

-A9

DTEP

FFUS*

When the toner drops

below a specific

volume, '0'.

TS1

J265

-3

-1

-1

-3

TH1

TH2

J267

-2

-1

-1

-2

J253

-5

-3

-6

-8

J251

-B14

-B13

-B7

-B8

J106

-B7

-B8

TH1

TH2

-2

-1

-9

-10

-12

-11

-B9

-B10

-14

-13

-B6

-B8

-B12

-B11

-B9

-B10

J106

-B9

-B10

VS1

POTON

POT

J103

-B1

-B2

-B3

-B4

When potential control

is being executed, '1'.

Analog correction to

suit the drum surface

potential. (See p. 4-5P.)

HUM1

+5V

HUM OUT

TH

J113

-A11

-A10

-A9

-A8

-A7

J8492

-1

-2

-3

-4

-5

J801

-A11

-A10

-A9

-A8

-A7

-A5

-A6

-A7

-A8

-A9

When the humidity

inside the machine

increases, the voltage

decreases. (analog signal)

When the temperature

inside the machine

increases, the voltage

decreases. (analog signal)

When the temperature of

the fixing roller increases,

the voltage decreases.

(analog signal)

When the temperature of

the fixing roller increases,

the voltage decreases.

(analog signal)

J162

-3

-2

-1

-1

-2

-3

J156

-3

-2

-1

-1

-2

-3

N.O.

MSW3

Fixing/feeding

lock sensor

J106

-A12

-A1

J271

-3

-1

-1

-3

J252

-3

-1

-11

-13

J251

-A9

-A20

-A12

-A1

When the fixing/feeding

unit is set, '0'.

J281

J283

-3

-14

-11

-13

Fixing/feeding relay PCB

J287

J282

Fixing/feeding relay PCB

Fixing main

thermistor

Fixing sub

thermistor

Potential

sensor

Environment

sensor

Potential

measurement

PCB

BD PCB

BD

+5V

BD*

J120

-1

-2

-3

J2701

-4

-3

-2

-1

J401

-1

-2

-3

-4

-4

-3

-2

When the laser beam

is detected, '0'.