T

echnical

B

ulletin

PAGE: 4/9

Reissued:06-Jan-12

Model:

Taurus-C1/P1 (D074/D075/M044)

Date:

25-Aug-11

No.:

RD074020a

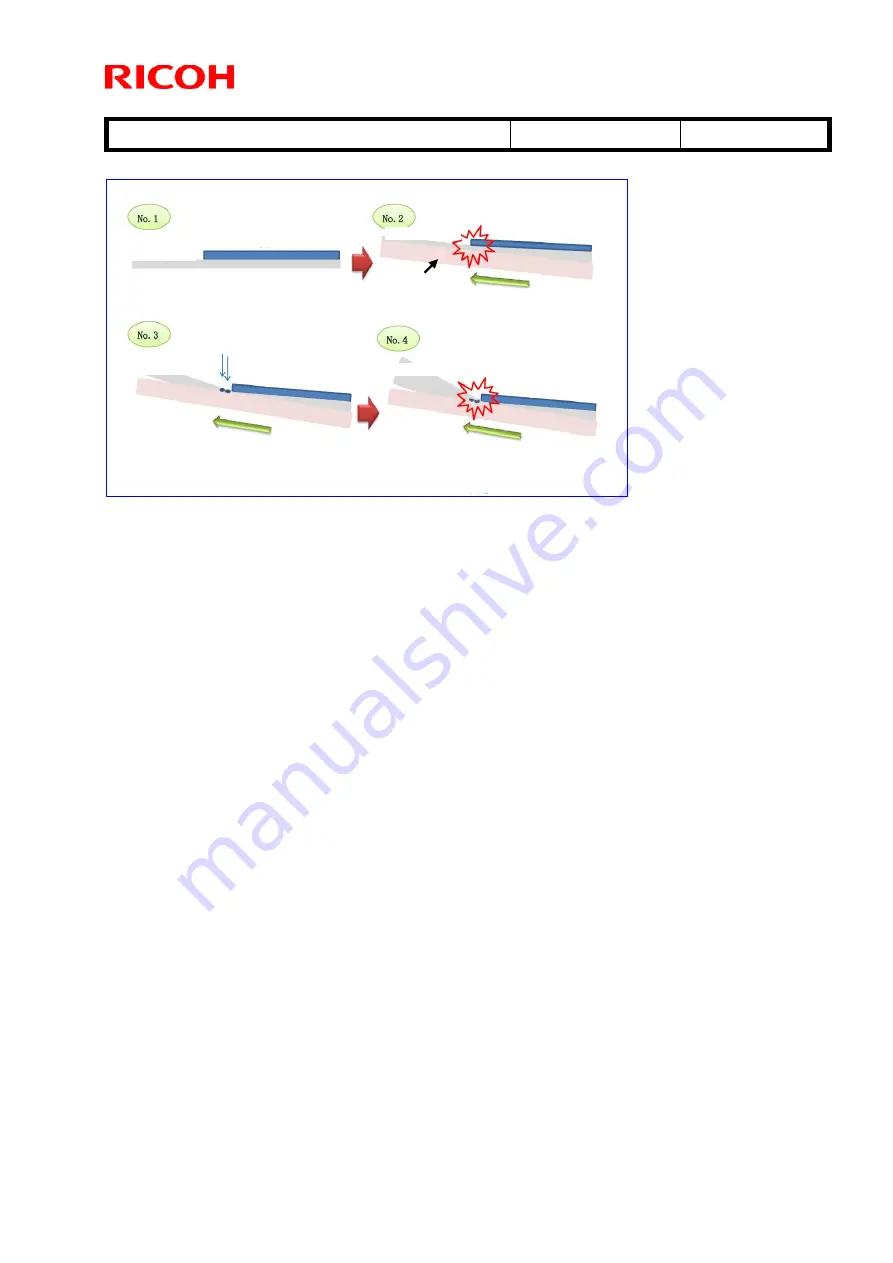

NOTE: The “Top Mylar” is not shown in the diagram above.

The bottom Mylar wears out in the location where it is in contact with the corner of the

middle Mylar, positioned immediately above. The bottom Mylar is squeezed between the

corner of the middle Mylar and the paper passing beneath, and this pressure and abrasion

damages and thins down the bottom Mylar.

Damage to the bottom Mylar is prominent when fed “Heavy” and “Large Sized” paper

stocks. Paper of “Weight 4” or heavier will tear away the bottom Mylar.

Required Action

Peel off and remove the bottom Mylar from the PTR entrance guide plate when making

new customer site installations by referring to the procedures described hereafter.

This rework will take approximately 10 minutes.

Please be noted that labor fee will not be compensated for this rework.

Feed Direction

Feed Direction

Feed Direction

Paper

Abrasion

Holes created

from continuous

abrasion

Breakage

Friction from feeding and pressure from

the middle Mylar and paper causes to

abrade the bottom Mylar.

Thinned down areas and holes cause

to tear apart the bottom Mylar.

Continuous abrasion thins

down and eventually creates

holes on the bottom Mylar.

Breakage of the Bottom Mylar Over Time

Middle Mylar

Bottom Mylar

Middle Mylar

Bottom Mylar

Middle Mylar

Bottom Mylar

Middle Mylar

Bottom Mylar