T

echnical

B

ulletin

PAGE: 2/2

Model:

Taurus-C1/P1 (D074/D075/M044)

Date:

02-Nov-11

No.:

RD074030

Cause

Symptoms “a” and “b” are both caused by the same mechanism.

The non-image area of the drum surface is unable to retrieve a surface potential equal to

the area where the solid image was created after quenching and recharging for the

halftone image to follow.

This occurs when the drum potential is low (= high development capacity). Due to the low

drum potential (insufficient negative charge), charge level of the previously non-image

area becomes too low when the image transfer current is applied.

Chances are higher for these symptoms to occur in the following conditions:

9

When printing halftone image immediately after printing a solid image

9

Low temperature and low humidity

9

Black images; the symptoms tends to occur with Black OPC drum

9

When applying fresh developer

Action

1. Do SP3011-002 (Manual ProCon: Exe – Density Adjustment)

Print out and check the result. If the problem persists, do the next step.

2. Decrease the power level of the quenching lamps in SP2224 to eliminate residual

charge on the drums.

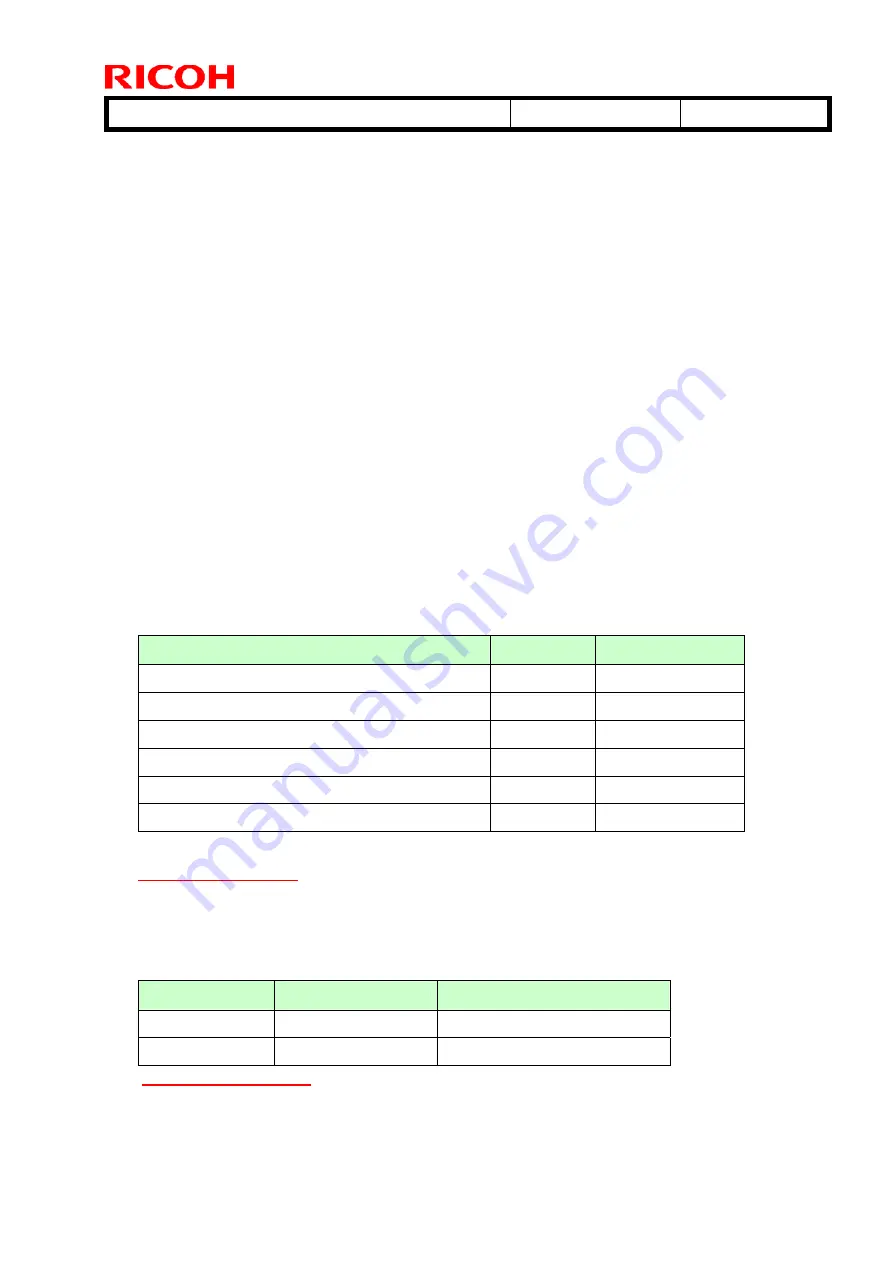

SP2204

-

Default

Set to*

001 (Standard process speed / Image area)

80%

5%

(0~20%)

002 (Standard process speed / Non-image area)

80%

5%

(0~20%)

003 (Medium process speed / Image area)

56%

5%

(0~20%)

004 (Medium process speed / Non-image area)

56%

5%

(0~20%)

005 (Low process speed / Image area)

40%

5%

(0~20%)

006 (Low process speed / Non-image area)

40%

5%

(0~20%)

Again, print out and check the result. If the problem persists, do the next step.

Possible side effect: Dirty background

3. Decrease the image transfer current for Black in SP2401.

Repeat SP3011-002 and check the result.

SP2401

-

Default

Set to*

005 33

28

(25~50%)

015 34

28

(25~50%)

Possible side effects: i) Light image density

ii) Toner contamination on drum surface