- 3.6 -

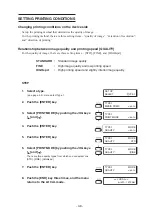

Troubleshooting

The following describes general troubleshooting. With some corrective mesures, problems may not

be solved depending on the medium used. If a problem cannot be solved after performing test

printing several times, stop using the plotter.

No.

Plobrems

Corrective measures

Remarks

1

Black lines occur.

1. Increase the media correction value.

If correction cannot be made with the

maximum correction value, set the

torque limiter setting of the run-out

side to the minimum value and then

perform printing.

2. Reduce the resistance of lapel bar.

• Reduce the number of lapel bars.

• Change the mount position of the lapel

bar so that the contact angle of the

medium be decreased.

(Refer to the previous page.)

2

White lines occur.

1. Reduce the media correction value.

2. Increase the resistance of the lapel bar.

• Increase the number of lapel bars.

• Change the mount position of the lapel

bar so that the contact angle of the

medium be increased.

(Refer to the previous page.)

3

2. Reduce the resistance of the lapel bar.

• Reduce the number of lapel bars.

• Change the mount position of the lapel

bar so that the contact angle of the

medium be decreased.

(Refer to the previous page.)

4

1. Make sure that the medium is normally

set to the rn-out device.

: Reset the medium.

2. Check whether a thin weak paper tube or

curved one is used.

: Replace the paper tube.

3. Change the mount position of the lapel

bar. Refer to the corrective measures of

No.1 (black lines) and No.2 (white lines).

Wrinkles occur on the

medium near the pinch

roller.

Black and white lines

occur at random.

This probrem occurs with

media which shrink when

plotted.

This probrem occurs mainly

with curved media and media

with local slacks.

This probrem occurs with

media which strech when

plotted.

Содержание TextileJet Tx2-1600 Series

Страница 2: ......

Страница 20: ...xvi...

Страница 88: ...2 12...

Страница 146: ...5 10...

Страница 153: ......

Страница 154: ...D200595 2 20 08032002...