3

© 2008 - 2011 TOSHIBA TEC CORPORATION All rights reserved

e-STUDIO2020C/2330C/2820C/2830C/3520C/3530C/4520C

ADJUSTMENT

3 - 1

3.

ADJUSTMENT

3.1

Image Related Adjustment

3.1.1

Adjustment Order

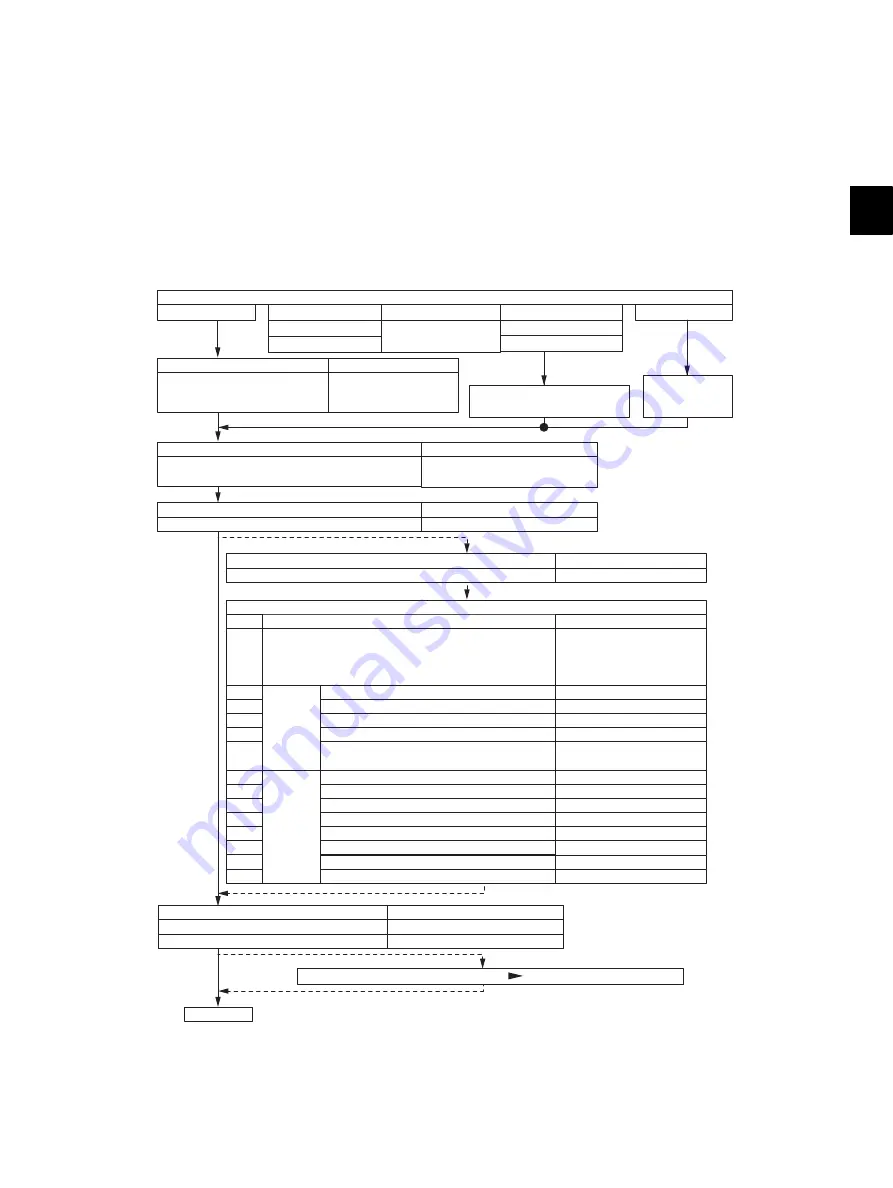

This chapter mainly explains the procedures for image related adjustment. When replacing

components which have other specified instructions for adjustment, those specified instructions are to

be obeyed in priority.

In the following diagram, the solid lines with arrow lead to essential adjustments, while the dotted lines

lead to adjustments to be performed if necessary.

Fig. 3-1

sensor(*2)

2

3

4

1

7

8

9

10

11

12

13

14

5

6

408, 440, 441, 444, 428, 442, 445

401

411

487

(a) Image distortion

(b) Reproduction ratio of primary scanning direction

(c) Image location of primary scanning direction

(d) Reproduction ratio of secondary scanning direction

(e) Image location of secondary scanning direction

(f) Top margin

(g) Right margin

(h) Bottom margin

–

405

306

340

305

430

432

433

498

(b) Primary scanning data laser writing start position

(c) Reproduction ratio of secondary scanning direction

(a) Reproduction ratio of primary scanning direction

(d) Secondary scanning data laser writing start position

(e) Primary scanning data laser writing start position at

duplexing

4100, 4101, 4103, 4104, 4105,

4106, 4107, 4108, 4109, 4110,

4111, 4115, 4116, 4117, 4118,

4120, 4122, 4123, 4124, 4125,

4126, 4127, 4128, 4129

396(*4)

Item to be adjusted

3.1.3 Adjustment of image quality control /

Automatic initialization of image quality control

Code in mode 05

Item to be adjusted

Code in mode 05

3.1.2 Adjustment of the auto-toner

Developer material

Image quality sensor(*1)

Needle electrode

Transfer belt(*1)

Image position aligning

sensor(*1)

Drum cleaning blade

Laser optical unit

1st transfer roller(*1)

Main charger grid

Photoconductive drum

3.1.6 Image dimensional adjustment

Items

Code in mode 05

3.1.7

.

Paper alignment at the registration roller

Order

3.1.9

3.1.8

Image

dimensional

adjustment

at the

printing

section

Image

dimensional

adjustment

at the

scanning

section

Adjust the image quality if necessary. (Chapter 3.1, 3.2, 3.3, 3.4, 3.5 )

END

Code in mode 05

1642(*5), (1644, 580)

1008(*6), 1004 - 0, 1004 - 2 to 8

Item to be adjusted

3.2.1 Automatic gamma adjustment (PPC)

3.3.1 Automatic gamma adjustment (PRT)

Parts to be replaced

Item to be adjusted

Code in mode 05

3.1.4 Adjustment of color registration control

4719

Item to be adjusted

Code in mode 05

3.1.5 Adjustment of the transfer belt due to environmental factors

408

*1: There is no need to perform counter clear.

*2: Adjust only the color changed.

*3: When the SRAM board <LGC board> has been replaced, perform the adjustment from 05-4721.

*4: When upgrading firmware, perform the adjustment from 05-396.

*5: Use [4] + [FAX] test pattern.

*6: Use [70] + [FAX] test pattern.

200(Y,M,C,K), 201(Yellow)

202(Magenta), 203(Cyan)

204(Black), 206(Y,M,C)

Life counter clear

([6]+[START]: PM support mode)

Tilt motor initial

excitation setting

(05-4721) (*3)