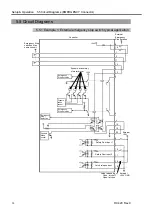

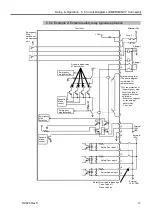

Setup & Operation 5.4 Pin Assignments (EMERGENCY connector)

RC420 Rev.9

37

5.4 Pin Assignments

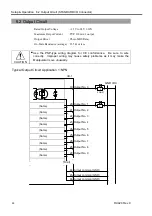

The EMERGENCY connector pin assignments are as follows:

Pin No.

Signal

Function

1 E_SW11

2 E_SW12

Emergency Stop switch output (1)

*3

3

E.STOP1+

Emergency Stop input 1 (+)

4

E.STOP1

-

Emergency Stop input 1 (

-

)

5 E.STOP

OUT

6 E.STOP

OUT

Emergency Stop condition output

(Relay contact)

*1

7 GUARD11

8 GUARD12

Safety Door input (1)

*2

9

+24V

+24 V output

10

+24VGND

+24 V GND output

11 E_SW21

12 E_SW22

Emergency Stop switch output (2)

*3

13

E.STOP2+

Emergency Stop input 2 (+)

14

E.STOP2

-

Emergency Stop input 2 (

-

)

15 RELEASE

16 RELEASE

Latch Release input

17 GUARD21

18 GUARD22

Safety Door input (2)

*2

19

+24V

+24 V output

20

+24VGND

+24 V GND output

*1 The Emergency Stop condition is output via relay contact when it is open (it is

normally closed).

*2 A critical error occurs if the input values from the Safety Door 1 and Safety Door 2

are different for two or more seconds. They must be connected to the same switch

with two sets of contacts.

*3 The signal from the Emergency Stop switch is designed to use two redundant circuits.

An error occurs if the statuses of the two redundant circuits are different for two or

more seconds. They must be connected to the same switch with two sets of

contacts.

Emergency Stop switch output rated load

+30V 1A or under

1-2, 11-12 pin

Emergency Stop rated input voltage range

Emergency Stop rated input current

+24V

±

10%

10mA/24V input

3-4, 13-14 pin

Safety Door rated input voltage range

Safety Door rated input current

+12 to 24V

±

10%

10mA/24V input

7-8, 17-18 pin

Latch Release rated input voltage range

Latch Release rated input current

+12 to 24V

±

10%

10mA/24V input

15-16 pin

Emergency Stop output relay contact rated

load

+30V 0.5A or under

5-6 pin

The total electrical resistance of the Emergency Stop switches and their circuit should be

1

Ω

or less.

)

NOTE

Summary of Contents for RC420

Page 1: ...Rev 9 EM073C1492F ROBOT CONTROLLER RC420 ...

Page 2: ...ROBOT CONTROLLER RC420 Rev 9 ...

Page 12: ...Setup Operation ...

Page 20: ...Setup Operation 1 Safety 10 RC420 Rev 9 ...

Page 30: ...Setup Operation 2 3 Controller Part Names and Functions 20 RC420 Rev 9 ...

Page 50: ...Setup Operation 5 5 Circuit Diagrams EMERGENCY Connector 40 RC420 Rev 9 ...

Page 58: ...Setup Operation 6 3 Pin Assignments STANDARD I O Connector 48 RC420 Rev 9 ...

Page 114: ...Setup Operation 10 UPS Uninterruptible Power Supply 104 RC420 Rev 9 ...

Page 115: ...97 Maintenance This manual contains maintenance procedures for the RC420 Robot Controller ...

Page 116: ...Maintenance RC420 Rev 9 106 ...

Page 138: ...Maintenance 6 Motor Driver Module 128 RC420 Rev 9 ...

Page 170: ...Maintenance 12 Recovering the HDD 160 RC420 Rev 9 ...