Delem

V1101, 9.26

Control voltage to part support system

The control voltage to the part support system can be tested in the module test of the diagnostic

program. The voltage can be varied between -255 and 255 DA-points, which resembles a range

between -10V and 10V.

The part support system should respond to the control signal as follows:

•

At a control signal of 0 V the part support should not move.

•

At a control signal of 40 mV (1 DA point for DA60 series controls) the part support should

not stand still and should reach a maximum speed of 0.5°/s. When the part support has an

angle range of e.g. 60°, it should take at least 120 s to move the part support from its

minimum to its maximum angle, at a control signal of 40 mV.

•

At a control signal of -40 mV, the part support should not stand still and the part support

should reach a maximum speed of 0.5°/s in the opposite direction. When the part support has

an angle range of e.g. 60°, it should take at least 120 s to move the part support from its

maximum to its minimum angle, at a control signal of -40 mV.

•

The relation between input voltage of the part support and the corresponding part support

speed should be linear. Non-linearity can have a bad influence on the part support

movement.

Potentiometer voltage

The feedback voltage from the potentiometer should have a large range between minimum and

maximum values which correspond with the minimum and maximum angle. This will benefit

the behaviour of the part support control system.

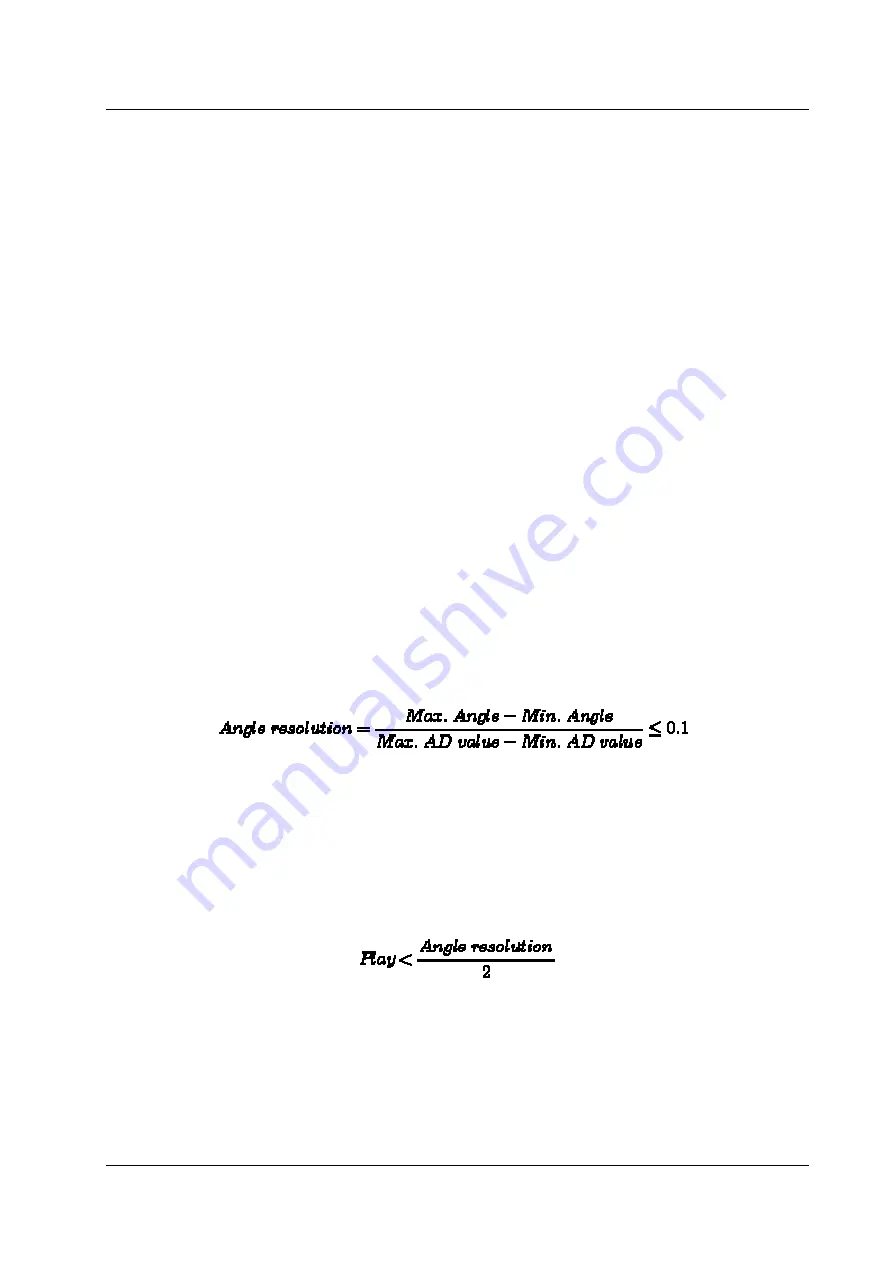

The feedback voltage is converted to AD points, ranging from 0 to 1023. In formula, the

potentiometer voltage has to meet the following requirement:

This means a difference of 1 AD point should correspond to a part support angle of maximal

0.1°.

Play and stiffness of mechanical construction

Play

The play of the potentiometer construction has to meet the following requirement:

Play can cause a worse standstill of the part support en can lead to an increment in overshoot.

Stiffness

The stiffness of the mechanical construction of the potentiometer has to be large enough to have

no negative influence on the measurement of the part support angle. An insufficient stiffness can

increase the maximum position error and can cause an increased overshoot.

Summary of Contents for DA-65

Page 1: ...Delem V0303 MACHINE PARAMETERS MANUAL DA 65 V7 DA 69 V7 DA 68PL V7 DA on Windows V1...

Page 17: ...Delem V1101 1 6...

Page 55: ...Delem V1101 3 16 Parameter 16 19 Not used...

Page 67: ...Delem V1101 3 28 Parameter 28 Not used...

Page 68: ...Delem V1101 3 29 Parameter 29 Not used...

Page 79: ...Delem V1101 3 40 Parameter 40 41 Not used...

Page 81: ...Delem V1101 3 43 Parameter 43 45 Not used...

Page 89: ...Delem V1101 3 53 Parameter 53 Not used...

Page 94: ...Delem V1101 3 58 Parameter 58 Not used...

Page 96: ...Delem V1101 3 60 Parameter 60 119 Not used...

Page 175: ...Delem V1101 6 5 6 4 Crowning parameters Figure 6 4 a...

Page 197: ...Delem V1101 8 3 8 3 Digital I axis parameters Figure 8 3 a...

Page 207: ...Delem V1101 9 5 Figure 9 2 c Figure 9 2 d...

Page 239: ......