Chapter 13

13-2

F-13-2

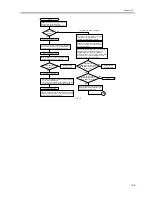

1. If there still is a difference in density after giving the adjusting screw 2 turns (each turn causing a change of about 0.7 mm), check the scanning lamp

and the scanner for soiling.

2. When making a clockwise turn, be sure that the intervals between wire grid runs are not larger than 9 mm.

When making a counterclockwise turn, be sure that the intervals between wire grid runs are not smaller than 7.5 mm.

MEMO:

Moving the wire from the photosensitive drum causes the image to be lighter, while moving it closer causes the images to be darker.

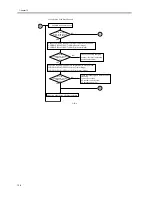

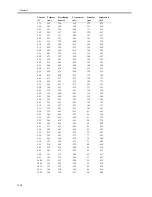

Is there a

difference in density between

front and rear?

Is the rear lighter?

Turn the adjusting screw

found at the front of the

primary charging assembly

clockwise. (2 full turns

Turn the adjusting screw

found at the rear of the

primary charging assembly

clockwise. (2 full turns max.)

Generate one print of a halftone

<

Checking the Density Slope

>

YES

NO

YES

NO

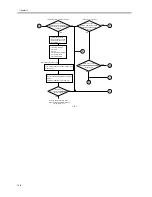

Are there vertical

lines in the image?

Are there vertical

lines in the image?

<

Checking Images

>

Checking Halftone Images

YES

YES

NO

NO

Execute forced

potential control.

Generate a halftone image.

Clean the following; also check

for foreign matter:

1. Dust-proofing glass

2. Charging assemblies

A

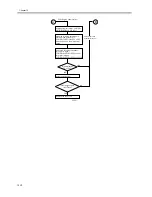

Make the selections in service mode, and

turn off and then on the main power switch:

COPIER>FUNCTION>DPC>DPC

Switch off and on the main power switch.

Summary of Contents for iR5570 Series

Page 1: ...Mar 29 2005 Service Manual iR6570 5570 Series ...

Page 2: ......

Page 6: ......

Page 26: ...Contents ...

Page 27: ...Chapter 1 Introduction ...

Page 28: ......

Page 30: ......

Page 55: ...Chapter 2 Installation ...

Page 56: ......

Page 58: ...Contents 2 9 3 Mounting the Cassette Heater 2 34 ...

Page 98: ......

Page 99: ...Chapter 3 Basic Operation ...

Page 100: ......

Page 102: ......

Page 110: ......

Page 111: ...Chapter 4 Main Controller ...

Page 112: ......

Page 114: ......

Page 135: ...Chapter 5 Original Exposure System ...

Page 136: ......

Page 181: ...Chapter 6 Laser Exposure ...

Page 182: ......

Page 184: ......

Page 192: ......

Page 193: ...Chapter 7 Image Formation ...

Page 194: ......

Page 198: ......

Page 259: ...Chapter 8 Pickup Feeding System ...

Page 260: ......

Page 350: ......

Page 351: ...Chapter 9 Fixing System ...

Page 352: ......

Page 401: ...Chapter 10 External and Controls ...

Page 402: ......

Page 406: ......

Page 448: ......

Page 449: ...Chapter 11 MEAP ...

Page 450: ......

Page 452: ......

Page 455: ...Chapter 12 Maintenance and Inspection ...

Page 456: ......

Page 458: ......

Page 468: ......

Page 469: ...Chapter 13 Standards and Adjustments ...

Page 470: ......

Page 505: ...Chapter 14 Correcting Faulty Images ...

Page 506: ......

Page 508: ......

Page 537: ...Chapter 15 Self Diagnosis ...

Page 538: ......

Page 540: ......

Page 565: ...Chapter 16 Service Mode ...

Page 566: ......

Page 568: ......

Page 633: ...Chapter 17 Upgrading ...

Page 634: ......

Page 636: ......

Page 641: ...Chapter 17 17 5 F 17 4 HDD Boot ROM Flash ROM System Software ...

Page 646: ...Chapter 17 17 10 F 17 11 8 Click START F 17 12 ...

Page 675: ...Chapter 17 17 39 F 17 59 2 Select the data to download F 17 60 3 Click Start ...

Page 677: ...Chapter 18 Service Tools ...

Page 678: ......

Page 680: ......

Page 683: ...Mar 29 2005 ...

Page 684: ......