Chapter 7

7-12

2. when the wire cleaning mechanism is executed in service mode:

COPIER>FUNCTION>CLEANING>WIRE-CLN*1

3. after the end of cleaning, at the end of every 2,000 prints*2

4. in a low temperature or high humidity environment, if the fixing roller is 160 deg C or less when the power is turned on

*1: The machine executes it when the primary charging wire or the transfer charging wire has been replaced.

*2: The default cleaning interval may be changed in service mode (COPIER> OPTION> BODY> W-CLN-P).

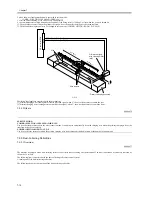

F-7-15

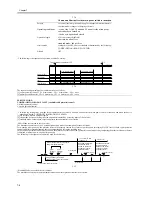

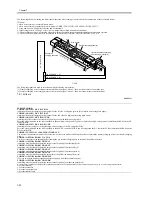

The following signals are associated with the mechanism:

[1] Primary charging wire cleaning motor reverse direction signal; when '1', the wire cleaner moves toward the rear.

[2] Primary changing wire cleaning motor normal direction signal; when '1', the wire cleaner moves toward the front.

7.5.2.3 Others

0009-4075

SERVICE MODE:

COPIER>FUNCTION>CLEANING>WIRE-CLN

Use it so that the machine causes the wire cleaner to make 5 round trips to automatically clean the charging wire when the primary charging wire or the

transfer wire has been replaced.

COPIER>OPTION>BODY>W-CLN-P

Use it to specify the interval at which the primary charging wire is automatically cleaned in terms of the number of prints made.

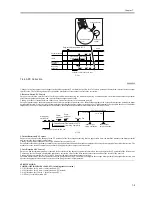

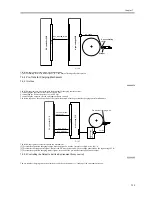

7.5.3 Dust-Collecting Roller Bias

7.5.3.1 Overview

0009-4077

The machine is equipped with a dust-colleting roller to collect stray toner occurring after development. The toner collected on its surface is removed by

the work of a scraper.

The following item is associated with the dust-collecting roller bias control system:

1. turning on/off the dust-collecting roller bias

The following shows the construction of the dust-collecting roller bias:

Primary changing assembly

Wire

DC controller PCB

(to rear)

(to front)

PRIMARY_CLEAN_OUT1 [1]

J103A

Wire cleaner

PRIMARY_CLEAN_OUT2 [2]

Primary charging

wire cleaning motor

(M6)

Summary of Contents for iR5570 Series

Page 1: ...Mar 29 2005 Service Manual iR6570 5570 Series ...

Page 2: ......

Page 6: ......

Page 26: ...Contents ...

Page 27: ...Chapter 1 Introduction ...

Page 28: ......

Page 30: ......

Page 55: ...Chapter 2 Installation ...

Page 56: ......

Page 58: ...Contents 2 9 3 Mounting the Cassette Heater 2 34 ...

Page 98: ......

Page 99: ...Chapter 3 Basic Operation ...

Page 100: ......

Page 102: ......

Page 110: ......

Page 111: ...Chapter 4 Main Controller ...

Page 112: ......

Page 114: ......

Page 135: ...Chapter 5 Original Exposure System ...

Page 136: ......

Page 181: ...Chapter 6 Laser Exposure ...

Page 182: ......

Page 184: ......

Page 192: ......

Page 193: ...Chapter 7 Image Formation ...

Page 194: ......

Page 198: ......

Page 259: ...Chapter 8 Pickup Feeding System ...

Page 260: ......

Page 350: ......

Page 351: ...Chapter 9 Fixing System ...

Page 352: ......

Page 401: ...Chapter 10 External and Controls ...

Page 402: ......

Page 406: ......

Page 448: ......

Page 449: ...Chapter 11 MEAP ...

Page 450: ......

Page 452: ......

Page 455: ...Chapter 12 Maintenance and Inspection ...

Page 456: ......

Page 458: ......

Page 468: ......

Page 469: ...Chapter 13 Standards and Adjustments ...

Page 470: ......

Page 505: ...Chapter 14 Correcting Faulty Images ...

Page 506: ......

Page 508: ......

Page 537: ...Chapter 15 Self Diagnosis ...

Page 538: ......

Page 540: ......

Page 565: ...Chapter 16 Service Mode ...

Page 566: ......

Page 568: ......

Page 633: ...Chapter 17 Upgrading ...

Page 634: ......

Page 636: ......

Page 641: ...Chapter 17 17 5 F 17 4 HDD Boot ROM Flash ROM System Software ...

Page 646: ...Chapter 17 17 10 F 17 11 8 Click START F 17 12 ...

Page 675: ...Chapter 17 17 39 F 17 59 2 Select the data to download F 17 60 3 Click Start ...

Page 677: ...Chapter 18 Service Tools ...

Page 678: ......

Page 680: ......

Page 683: ...Mar 29 2005 ...

Page 684: ......