Chapter 7

7-8

F-7-9

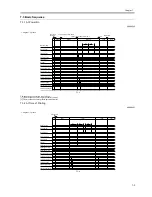

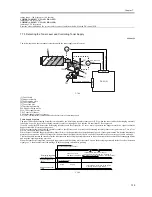

7.4.4 Determining the Laser Output

0009-3543

To measure the light area potential (VL1) for the first time after the power switch is turned on, the machine uses the most recent laser output level (LP0),

and measures the drum surface potential using the potential sensor. The DC controller PCB compares the drum source potential and the target potential;

if the measured potential is +/-10V of the target value, the machine corrects the potential of the laser output, and measures the potential once again. The

machine executes potential measurement a maximum of 8 times, and also corrects the lower output level as many times. In addition, the machine measures

the light area (VL2) for the developing bias for use in determining the laser output (LP) needed to attain the target potential.

F-7-10

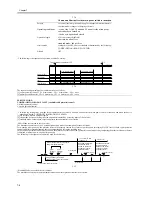

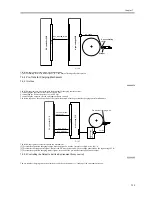

7.4.5 Determining the Developing Bias

0009-3544

The machine determines the developing bias (VDC) as follows with reference to the drum surface potential (VL2):

VDC = VL2 + delta VDC

For copier potential, delta VDC=110 V

For printer potential, delta VDC=85 to 110 V (i.e., the printer potential varies to suit the reading of the environment sensor, thus ensuring the reproduction

of correct line width)

WMUPR

WMUP

STBY

200 C

Potential sensor

Primary charging

Grid bias

Vpc

Vpc

Vpc

Vpc

VD

+6V

-6V

VD

VD

Correction control

sequence start

Potential control

sequence start

Previous potential

VD

VD

VD

VD

VD

VD

Target VD

Fixing assembly temperature 195 C

WMUPR

WMUP

STBY

200˚C

Potential sensor

Developing bias

(DC)

Laser

LP0

LP0 LP0 LP0

LP0

LP

VL1 VL1 VL1 Target VL1

VL1

VL1

Correction control

sequence start

Fixing assembly

temperature 195 Deg C

VL1

+6V

-6V

VL1

VL1

VL1

Previous potential

Target VL1

Potential control

sequence start

VL2

Summary of Contents for iR5570 Series

Page 1: ...Mar 29 2005 Service Manual iR6570 5570 Series ...

Page 2: ......

Page 6: ......

Page 26: ...Contents ...

Page 27: ...Chapter 1 Introduction ...

Page 28: ......

Page 30: ......

Page 55: ...Chapter 2 Installation ...

Page 56: ......

Page 58: ...Contents 2 9 3 Mounting the Cassette Heater 2 34 ...

Page 98: ......

Page 99: ...Chapter 3 Basic Operation ...

Page 100: ......

Page 102: ......

Page 110: ......

Page 111: ...Chapter 4 Main Controller ...

Page 112: ......

Page 114: ......

Page 135: ...Chapter 5 Original Exposure System ...

Page 136: ......

Page 181: ...Chapter 6 Laser Exposure ...

Page 182: ......

Page 184: ......

Page 192: ......

Page 193: ...Chapter 7 Image Formation ...

Page 194: ......

Page 198: ......

Page 259: ...Chapter 8 Pickup Feeding System ...

Page 260: ......

Page 350: ......

Page 351: ...Chapter 9 Fixing System ...

Page 352: ......

Page 401: ...Chapter 10 External and Controls ...

Page 402: ......

Page 406: ......

Page 448: ......

Page 449: ...Chapter 11 MEAP ...

Page 450: ......

Page 452: ......

Page 455: ...Chapter 12 Maintenance and Inspection ...

Page 456: ......

Page 458: ......

Page 468: ......

Page 469: ...Chapter 13 Standards and Adjustments ...

Page 470: ......

Page 505: ...Chapter 14 Correcting Faulty Images ...

Page 506: ......

Page 508: ......

Page 537: ...Chapter 15 Self Diagnosis ...

Page 538: ......

Page 540: ......

Page 565: ...Chapter 16 Service Mode ...

Page 566: ......

Page 568: ......

Page 633: ...Chapter 17 Upgrading ...

Page 634: ......

Page 636: ......

Page 641: ...Chapter 17 17 5 F 17 4 HDD Boot ROM Flash ROM System Software ...

Page 646: ...Chapter 17 17 10 F 17 11 8 Click START F 17 12 ...

Page 675: ...Chapter 17 17 39 F 17 59 2 Select the data to download F 17 60 3 Click Start ...

Page 677: ...Chapter 18 Service Tools ...

Page 678: ......

Page 680: ......

Page 683: ...Mar 29 2005 ...

Page 684: ......