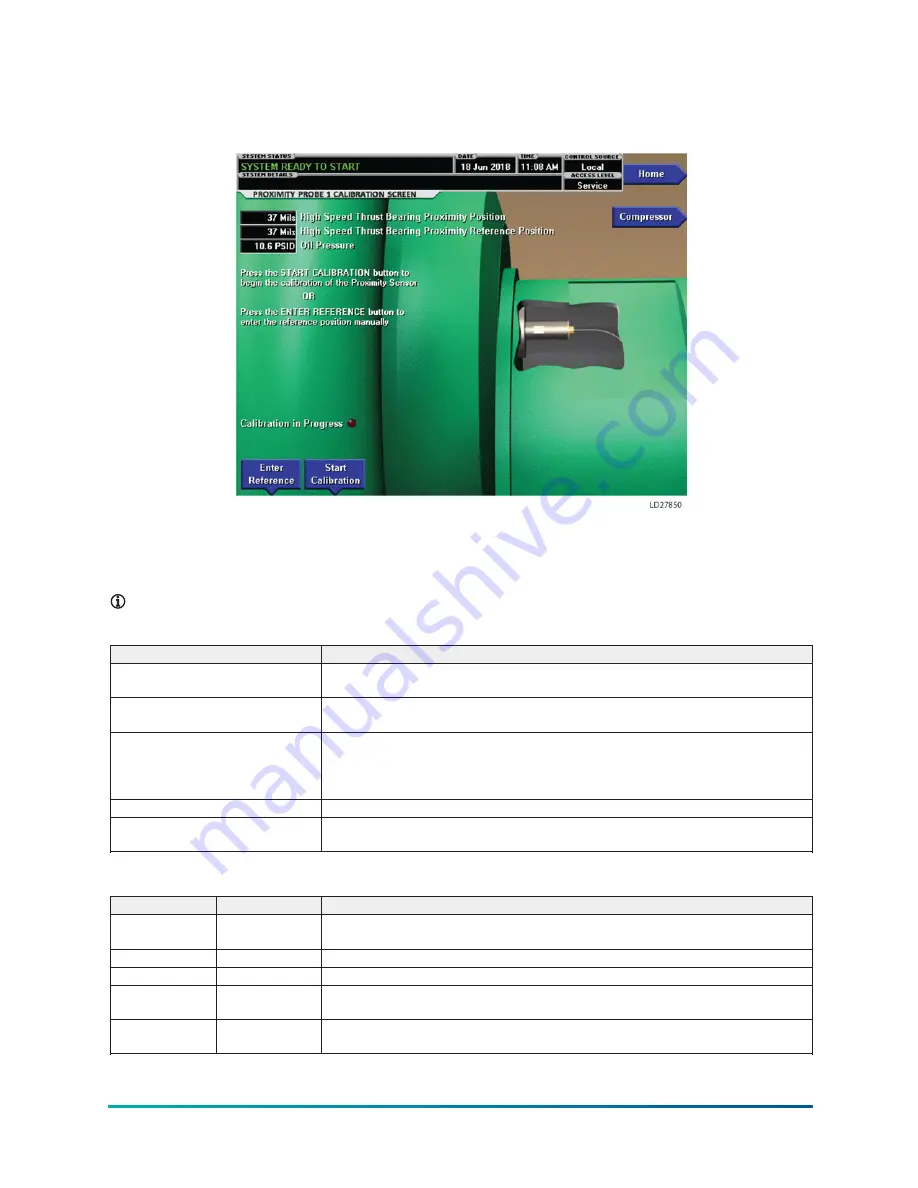

Proximity probe calibration screen

Figure 12: Proximity probe calibration screen

This screen displays a cutaway view of the chiller compressor, revealing the proximity probe sensor

and provides the capability of calibrating the proximity probe sensor. The appearance of this screen

is the same for compressor #1 and compressor #2.

Note:

Requires a login access level of SERVICE.

Table 21: Display only fields

Field/LED name

Description

High speed thrust bearing proximity

position

Displays the distance between the high-speed thrust collar and the proximity probe

that is used to measure the position.

High speed thrust bearing proximity

reference position

Displays the presently defined offset reference position. This value is defined at the

conclusion of a calibration sequence.

Oil pressure

Displays the pressure differential between the pump oil pressure transducer

(compressor bearing input) and the sump oil pressure transducer. If either of the

transducers used to calculate this differential is out of range, the display field will show

XX.X.

Calibration in progress (LED)

Indicates that the calibration sequence is in progress.

Calibration messages

These are text messages which step the user through the calibration process and

indicate its success or failure.

Table 22: Programmable

Button

Access level

Description

Enter reference

Service

Allows the Service Technician to enter a previously recorded reference when replacing

a microboard.

Start calibration Service

This starts the calibration procedure. This key is hidden after calibration has started.

Cancel calibration Service

This option only becomes available after the calibration has started.

Accept calibration Service

The key is pressed to accept the calibration. This key option only becomes available

after the calibration sequence is complete.

Fault

acknowledge

Service

This option is only displayed if a fault is present. Allows clearing of High Speed Thrust

Bearing related shutdowns.

Model YD Mod D with OptiView Control Center

44

Содержание YD Mod D

Страница 2: ...2 Model YD Mod D with OptiView Control Center...

Страница 8: ...Nomenclature Model YD Mod D with OptiView Control Center 8...

Страница 17: ...Figure 2 Chiller operation flow chart 17 Model YD Mod D with OptiView Control Center...

Страница 18: ...Figure 2 Chiller operation flow chart Model YD Mod D with OptiView Control Center 18...

Страница 19: ...Figure 2 Chiller operation flow chart 19 Model YD Mod D with OptiView Control Center...

Страница 20: ...Figure 2 Chiller operation flow chart Model YD Mod D with OptiView Control Center 20...

Страница 21: ...Figure 2 Chiller operation flow chart 21 Model YD Mod D with OptiView Control Center...

Страница 22: ...Figure 2 Chiller operation flow chart Model YD Mod D with OptiView Control Center 22...

Страница 150: ...Figure 57 Sample printout status Model YD Mod D with OptiView Control Center 150...

Страница 151: ...Figure 57 Sample printout status 151 Model YD Mod D with OptiView Control Center...

Страница 152: ...Figure 58 Sample printout setpoints Model YD Mod D with OptiView Control Center 152...

Страница 153: ...Figure 58 Sample printout setpoints 153 Model YD Mod D with OptiView Control Center...

Страница 154: ...Figure 59 Sample printout schedule Model YD Mod D with OptiView Control Center 154...

Страница 155: ...Figure 60 Sample printout sales order 155 Model YD Mod D with OptiView Control Center...

Страница 156: ...Figure 61 Sample printout history Model YD Mod D with OptiView Control Center 156...

Страница 157: ...Figure 61 Sample printout history 157 Model YD Mod D with OptiView Control Center...

Страница 159: ...Figure 64 Sample printout custom screen report 159 Model YD Mod D with OptiView Control Center...