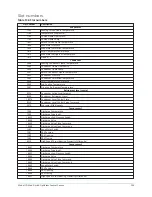

Table 140: Warning messages

Message

Description

Warning – Surge

Protection – Excess

Surge Limit

This warning applies to single compressor operation only and only if the

Surge

Protection Extended Run

setpoint is enabled. The chiller is operating in a

Surge

Protection Extended Run

period because the

Surge Window Count

has exceeded

the

Count Limit

setpoint during single compressor operation. When the

Surge Window

Count

exceeds the

Count Limit

setpoint, a 10 minute extended run period is initiated.

During this period, the pre-rotation vanes are driven closed. At the end of the 10 minute

period, if the

Surge Window Count

is less than the

Count Limit

, this message is cleared

and vanes are allowed to load. Otherwise, another 10 minute extended run period is

initiated.

Warning – Setpoint

Override

A blank BRAM battery-backed memory device (IC location U52 on Microboard) or a failure of

this device was detected during the initialization process that occurs when power is applied

to the control center. Due to this failure, any or all of the programmed setpoints could have

been corrupted. Therefore, all setpoints have been automatically changed to their default

values. All setpoints will have to be programmed to their required values. This message will

clear when the

Warning Reset

key is pressed in operator (or higher) access level.

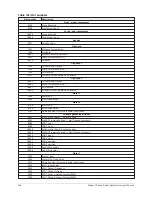

Warning – Condenser –

High Pressure Limit

The condenser pressure exceeds the

High Pressure Warning

setpoint threshold,

programmed by a service technician logged in at service access level. While this condition

is in effect, the pre-rotation vanes are inhibited from further opening. This message

automatically clears and the vanes are permitted to open when the condenser pressure

decreases to 5 psig below the setpoint.

Warning – Evaporator –

Low Pressure Limit

The evaporator pressure has decreased to the warning threshold. This threshold is fixed in

water cooling applications. In brine cooling applications, the threshold is a fixed amount

above the programmable safety shutdown threshold. The safety threshold in brine

applications is determined by the brine solution and is determined by the YORK factory.

While this condition is in effect, the pre-rotation vanes are inhibited from further opening.

Warning threshold (psig)

Reset threshold (psig)

Water

Brine

Water

Brine

R-134a

27.0

+2.0 >Safety setpoint

28.0

+3.0>Safety setpoint

This message automatically clears and the vanes are permitted to open when the evaporator

pressure increases to the reset value.

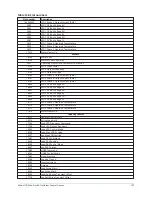

Warning – Motor Bearing

Lube Suggested

The operating hours since last motor lubrication has exceeded 1000 hours (the greater

of either

Motor #1 Operating Hours

or

Motor #2 Operating Hours

is used for this

calculation). This warning will be displayed until manually cleared by the operator or the

Operating Hours Since Last Motor Lubrication

exceed 1200 hours, whereupon

it is replaced by the message

Warning – Motor Bearing Lube Required

below. The

operator clears this message by entering his/her initials, name or user ID in operator access

level (or higher) using the

Motor Lube Acknowledge

key on the Motor lubrication screen.

for entry instructions. This entry implies both motors

were lubricated. The date and time of this entry is automatically logged as the

Date of

Last Motor Lubrication

and

Time of Last Motor Lubrication

. It also resets the

Operating Hours Since Last Lubrication

to zero. The date this warning occurs is

stored as the

Date of Last Motor Lubrication Warning or Fault

. This warning

message will only be displayed if the

Auto lube

setpoint on the Motor lubrication screen is

disabled.

Model YD Mod D with OptiView Control Center

134

Содержание YD Mod D

Страница 2: ...2 Model YD Mod D with OptiView Control Center...

Страница 8: ...Nomenclature Model YD Mod D with OptiView Control Center 8...

Страница 17: ...Figure 2 Chiller operation flow chart 17 Model YD Mod D with OptiView Control Center...

Страница 18: ...Figure 2 Chiller operation flow chart Model YD Mod D with OptiView Control Center 18...

Страница 19: ...Figure 2 Chiller operation flow chart 19 Model YD Mod D with OptiView Control Center...

Страница 20: ...Figure 2 Chiller operation flow chart Model YD Mod D with OptiView Control Center 20...

Страница 21: ...Figure 2 Chiller operation flow chart 21 Model YD Mod D with OptiView Control Center...

Страница 22: ...Figure 2 Chiller operation flow chart Model YD Mod D with OptiView Control Center 22...

Страница 150: ...Figure 57 Sample printout status Model YD Mod D with OptiView Control Center 150...

Страница 151: ...Figure 57 Sample printout status 151 Model YD Mod D with OptiView Control Center...

Страница 152: ...Figure 58 Sample printout setpoints Model YD Mod D with OptiView Control Center 152...

Страница 153: ...Figure 58 Sample printout setpoints 153 Model YD Mod D with OptiView Control Center...

Страница 154: ...Figure 59 Sample printout schedule Model YD Mod D with OptiView Control Center 154...

Страница 155: ...Figure 60 Sample printout sales order 155 Model YD Mod D with OptiView Control Center...

Страница 156: ...Figure 61 Sample printout history Model YD Mod D with OptiView Control Center 156...

Страница 157: ...Figure 61 Sample printout history 157 Model YD Mod D with OptiView Control Center...

Страница 159: ...Figure 64 Sample printout custom screen report 159 Model YD Mod D with OptiView Control Center...