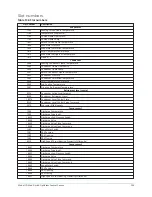

Table 137: Status messages

Message

Description

System Run

The chiller is running under the condition described in the Details Line of the Status Bar.

System Coastdown

The chiller has shut down and the Post-run lubrication is being performed.

System Start Inhibit

The chiller is prevented from being started due to the reason displayed on the Details Line of

the Status bar.

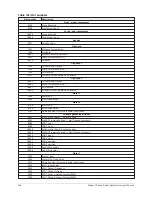

Run messages

Table 138: Run messages

Message

Description

Leaving Chilled Liquid

Control

The chiller is running, controlling the

Leaving Chilled Liquid to the Leaving

Chilled Liquid Temperature Setpoint

. There are no system conditions inhibiting this

operation.

System In Lead

Compressor Pulldown

Displayed while a

Lead Compressor Pulldown Time Setpoint

(0-255 minutes) is in

effect. The time remaining in the period is also displayed. For the duration of this period,

only the lead compressor will be permitted to run. The lag compressor will not be brought

on line during this period. A current limit may be applied to the lead motor during this

period using the

Lead Compressor Pulldown Demand Limit Setpoint

(30-100%). See

the complete explanation in

Description of system and fundamentals of operation

Lead Motor-high Current

Limit

Either the

Lead Compressor Pulldown Demand Time Setpoint

is in effect and the lead

compressor motor current is being limited by the

Lead Compressor Pulldown Demand

Limit Setpoint

, or the

Lead Compressor Pulldown Demand Time Setpoint

has

elapsed and the lead compressor motor current is being limited by the

Chiller Current

Limit Setpoint

.

Refer to the

for details of the conditions above.

When the motor current increases to the

inhibit open

threshold, the pre-rotation vanes are

inhibited from further opening. This prevents a further current rise. If the current continues

to rise to the

start close

threshold, the Vanes begin closing until the current falls to the

stop

close

threshold. Automatic vane operation is resumed and this message automatically clears

when the motor current decreases to the

allow open

threshold.

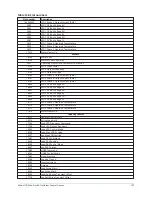

Lag Compressor Prelube

A start has been initiated on the lag compressor and the 50 second pre-start lubrication is

being performed.

Lag Compressor

Coastdown

The lag compressor has shutdown and the 150 second post-run lubrication is being

performed on the lag compressor.

Lag Compressor

Unloading Before

Shutdown

Displayed while the pre-rotation vanes and discharge valves are closing during a soft

shutdown of the lag compressor.

Vanes #1 Start Inhibit-

motor Switch Open

Compressor #1 is inhibited from starting because its pre-rotation vanes are not fully closed

(Vane motor switch open), but compressor #2 is able to run and thus the chiller is not

prevented from operating. This message clears when the vanes have fully closed.

Vanes #2 Start Inhibit-

motor Switch Open

Compressor #2 is inhibited from starting because its pre-rotation vanes are not fully closed

(Vane motor switch open), but compressor #1 is able to run and thus the chiller is not

prevented from operating. This message clears when the vanes have fully closed.

Motor #1 Start Inhibit

– Anti-recycle

Compressor #1 is inhibited from starting because its 30 minute anti-recycle period is in

effect, but compressor #2 is able to run. This message clears when the 30 minute timer

expires.

Motor #2 Start Inhibit

– Anti-recycle

Compressor #2 is inhibited from starting because its 30 minute anti-recycle period is in

effect, but compressor #1 is able to run. This message clears when the 30 minute timer

expires.

Model YD Mod D with OptiView Control Center

130

Содержание YD Mod D

Страница 2: ...2 Model YD Mod D with OptiView Control Center...

Страница 8: ...Nomenclature Model YD Mod D with OptiView Control Center 8...

Страница 17: ...Figure 2 Chiller operation flow chart 17 Model YD Mod D with OptiView Control Center...

Страница 18: ...Figure 2 Chiller operation flow chart Model YD Mod D with OptiView Control Center 18...

Страница 19: ...Figure 2 Chiller operation flow chart 19 Model YD Mod D with OptiView Control Center...

Страница 20: ...Figure 2 Chiller operation flow chart Model YD Mod D with OptiView Control Center 20...

Страница 21: ...Figure 2 Chiller operation flow chart 21 Model YD Mod D with OptiView Control Center...

Страница 22: ...Figure 2 Chiller operation flow chart Model YD Mod D with OptiView Control Center 22...

Страница 150: ...Figure 57 Sample printout status Model YD Mod D with OptiView Control Center 150...

Страница 151: ...Figure 57 Sample printout status 151 Model YD Mod D with OptiView Control Center...

Страница 152: ...Figure 58 Sample printout setpoints Model YD Mod D with OptiView Control Center 152...

Страница 153: ...Figure 58 Sample printout setpoints 153 Model YD Mod D with OptiView Control Center...

Страница 154: ...Figure 59 Sample printout schedule Model YD Mod D with OptiView Control Center 154...

Страница 155: ...Figure 60 Sample printout sales order 155 Model YD Mod D with OptiView Control Center...

Страница 156: ...Figure 61 Sample printout history Model YD Mod D with OptiView Control Center 156...

Страница 157: ...Figure 61 Sample printout history 157 Model YD Mod D with OptiView Control Center...

Страница 159: ...Figure 64 Sample printout custom screen report 159 Model YD Mod D with OptiView Control Center...