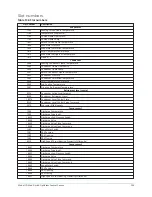

Table 140: Warning messages

Message

Description

Warning – Head Pressure

– High Head Lag Start

Limit

Displayed when starting the lag compressor while a high head condition exists. A high head

condition exists when the actual

Delta P/P

is greater than the

High Head DP/P Limit

setpoint. To minimize surging while starting the lag compressor under this condition, the

lead compressor’s pre-rotation vanes are driven closed coincident with the start of the lag

compressor’s pre-lube. They will be allowed to open after the lag compressor is running, the

lag discharge valve is open and the lead and lag motor currents are balanced within 5%.

Warning – Anti Surge –

Excess Surge Limit

This warning applies to dual compressor operation only. The pre-rotation vanes are being

load limited because a surge event has been detected while both compressors are running.

As a surge avoidance, a close signal is applied to both the lead and lag compressor vanes

until the lowest motor current is greater than or equal to 80% of the highest motor current.

The load limit will remain in effect until the lag compressor is shutdown, whereupon the

message is cleared.

Warning – Anti Surge –

Surge Count Exceeded

This warning applies to dual compressor operation only. The

Surge Window Count

exceeded the

Count Limit

while both compressors were running. To prevent further

surging, a soft shutdown is performed on the lag compressor when this warning is

displayed. This message will be displayed until manually cleared with the

Warning Reset

key

in operator (or higher) access level.

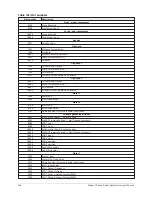

Warning – Compressor #1

Locked Out

Compressor 1 is inhibited from starting because it has been placed in service lockout. This is

performed on the Compressor capacity cycling screen.

Warning – Compressor #2

Locked Out

Compressor 2 is inhibited from starting because it has been placed in service lockout. This is

performed on the Compressor capacity cycling screen.

Warning – Oil Pump #1 –

Seal Lubrication - Low

Pressure

A minimum of 15 psid of oil pressure was not achieved in the first 30 seconds of the seal

lubrication cycle (or it dropped below this value during the remaining 90 seconds of the

cycle) for compressor 1. This message must be manually cleared using the

Warning Reset

key in Service access level (or higher). As soon as the message is cleared, another seal

lubrication will be attempted. The message will also be cleared if Standby Lube 1 is disabled

on Oil pump 1 screen or compressor 1 enters the prelube state.

Warning – Oil Pump #2 –

Seal Lubrication - Low

Pressure

A minimum of 15 psid of oil pressure was not achieved in the first 30 seconds of the seal

lubrication cycle (or it dropped below this value during the remaining 90 seconds of the

cycle) for compressor 2. This message must be manually cleared using the

Warning Reset

key in service access level (or higher). As soon as the message is cleared, another seal

lubrication will be attempted. The message will also be cleared if standby lube 2 is disabled

on Oil pump 2 screen or compressor 1 enters the prelube state.

Warning – Low Oil Level

Displayed if the oil level in the oil sump is less than the minimum oil level as shown below.

Condition

Minimum oil level

No compressors running

50%

1 compressor running

40%

2 compressors running

30%

It will automatically clear when the level is greater than the minimum oil level.

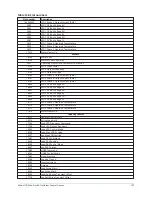

Warning – Oil Pump #1

– Seal Lubrication In

Progress

The 2 minute seal lubrication cycle (that occurs once every 24 hours while the compressor 1

is not running) is in progress for compressor 1.

Warning – Oil Pump #2

– Seal Lubrication In

Progress

The 2 minute seal lubrication cycle (that occurs once every 24 hours while compressor 2 is

not running) is in progress for compressor 2.

Warning – Vanes #1 –

Uncalibrated

The pre-rotation vanes calibration procedure has not been performed on compressor 1.

Warning – Vanes #2 –

Uncalibrated

The pre-rotation vanes calibration procedure has not been performed on compressor 2

Warning – Surge

Protection - Excess

Surge Detected

This warning applies only to single compressor operation and only if the

Surge

Protection Shutdown

setpoint is disabled. The

Surge Window Count

has exceeded the

Count Limit

setpoint during single compressor operation. This message can be cleared

with the

Warning Reset

key in operator access level (or higher) after the

Surge Window

Count

is less than the

Count Limit

.

133

Model YD Mod D with OptiView Control Center

Содержание YD Mod D

Страница 2: ...2 Model YD Mod D with OptiView Control Center...

Страница 8: ...Nomenclature Model YD Mod D with OptiView Control Center 8...

Страница 17: ...Figure 2 Chiller operation flow chart 17 Model YD Mod D with OptiView Control Center...

Страница 18: ...Figure 2 Chiller operation flow chart Model YD Mod D with OptiView Control Center 18...

Страница 19: ...Figure 2 Chiller operation flow chart 19 Model YD Mod D with OptiView Control Center...

Страница 20: ...Figure 2 Chiller operation flow chart Model YD Mod D with OptiView Control Center 20...

Страница 21: ...Figure 2 Chiller operation flow chart 21 Model YD Mod D with OptiView Control Center...

Страница 22: ...Figure 2 Chiller operation flow chart Model YD Mod D with OptiView Control Center 22...

Страница 150: ...Figure 57 Sample printout status Model YD Mod D with OptiView Control Center 150...

Страница 151: ...Figure 57 Sample printout status 151 Model YD Mod D with OptiView Control Center...

Страница 152: ...Figure 58 Sample printout setpoints Model YD Mod D with OptiView Control Center 152...

Страница 153: ...Figure 58 Sample printout setpoints 153 Model YD Mod D with OptiView Control Center...

Страница 154: ...Figure 59 Sample printout schedule Model YD Mod D with OptiView Control Center 154...

Страница 155: ...Figure 60 Sample printout sales order 155 Model YD Mod D with OptiView Control Center...

Страница 156: ...Figure 61 Sample printout history Model YD Mod D with OptiView Control Center 156...

Страница 157: ...Figure 61 Sample printout history 157 Model YD Mod D with OptiView Control Center...

Страница 159: ...Figure 64 Sample printout custom screen report 159 Model YD Mod D with OptiView Control Center...