84

The

fol

lo

w

in

g l

e

a

k

ag

e a

n

d

cl

og

gi

ng

che

ck m

a

y n

o

t w

o

rk

pr

o

per

ly

i

f t

he

ou

tdo

or

te

mp

er

at

ur

e i

s

l

o

w

an

d th

e r

e

fr

ig

er

an

t i

s

hi

be

rn

at

in

g.

In

this ca

se,

set

the

op

eratin

g t

ime

un

til

the

che

ck lon

ge

r.

(A

pp

ro

xi

ma

te gu

id

e: Di

sch

ar

ge

te

mp

er

at

ur

e

TD

1

,

TD

2, and

TD

3 60 °C or

hi

g

h

e

r)

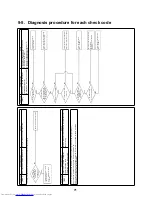

(*1

)Check th

e va

lve lea

kage an

d cl

ogg

ing

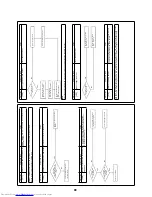

a)

C

heck the SV3A valve leakage (Performed

only in the outdo

or unit linkage system)

•

T

ur

n

off

the

p

o

wer

, r

e

mo

ve t

h

e

SV3

A va

lve co

nn

ecto

r,

tur

n

on

th

e p

o

wer

a

nd

the

n st

ar

t th

e

test

ru

n.

•

W

h

ile

th

e

o

u

td

oo

r u

n

it

is ru

nn

in

g,

che

ck th

e

t

e

mp

era

tu

re

ch

an

ge

on

th

e S

V

3

A

valve

seco

nd

ar

y.

–Fig

ur

e (1

)

ĺ

If

th

e te

m

p

er

a

tur

e

bec

om

es h

igh,

th

e SV

3A

val

ve

l

eaka

ge

ha

s occ

ur

re

d.

Re

pl

a

c

e th

e

SV3

A va

lve

.

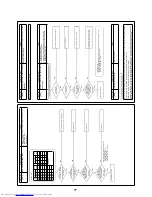

b)

C

heck the SV3C

valve leakage

•

u

rn

off

th

e p

o

wer

, r

e

mo

ve t

h

e

SV3

C valve

con

ne

ctor

, t

u

rn

o

n

t

h

e

po

w

e

r an

d th

en

sta

rt

the

te

st r

u

n

.

•

A

ft

er

se

ver

al

-m

in

u

te

op

er

at

io

n,

che

ck th

e te

m

per

a

tur

e

on

the

SV

3C

va

lve

sec

ond

a

ry.–

Fig

u

re

(2

)

ĺ

If

th

e te

m

p

er

a

tur

e

bec

om

es h

igh

(e

qu

iv

al

en

t to

di

sch

ar

ge

tem

p

e

ratu

re

TD

),

th

e S

V

3

C

val

ve l

e

aka

ge

ha

s

occu

rre

d.

Re

pl

ace

t

h

e S

V

3

C va

lve.

(Eve

n if

the

SV

3C va

lv

e

lea

kag

e

h

a

s n

o

t

occu

rr

ed

, th

e

tempe

ratu

re

on

th

e S

V

3C va

lve se

con

da

ry

r

ise

s du

ri

n

g

op

er

at

io

n.

(L

ow

er t

h

an

d

is

c

h

ar

ge

te

mp

er

at

ur

e TD)

)

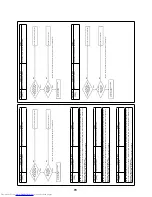

c)

C

heck the SV3F

va

lve le

akage

•

T

u

rn o

ff t

h

e po

we

r,

rem

ov

e

th

e

S

V

3

F v

a

lv

e c

o

nn

ec

to

r,

tu

rn

on

th

e p

o

w

e

r a

n

d

th

e

n

s

tar

t t

h

e t

e

s

t ru

n.

•

A

ft

er

se

ver

al

-m

in

u

te

op

er

at

io

n,

che

ck th

e te

m

per

a

tur

e

on

the

SV

3F va

lve

se

cond

ar

y.–

Fig

u

re

(3

)

ĺ

If

th

e te

m

p

er

a

tur

e

bec

om

es h

igh,

th

e SV

3F va

lve le

akag

e

has

occu

rr

ed

. Re

place

the

SV

3F va

lve.

d)

C

heck the SV3B valve cloggin

g (Perfo

rmed only in th

e outdoor unit linkag

e system)

•

S

e

t [

S

W

0

1

/

SW

02

/

SW

03]

to

[2

/

1

/ 3

]

(7

-se

gm

en

t

display

[Hr

][..

. ..

. .

..])

wh

ile

th

e

out

do

or

u

n

it is

ru

nn

ing,

an

d

the

n

pr

e

ss [SW

0

4] f

o

r 2

seco

nds

or

lon

g

er

.

•

S

e

t [S

W0

2]

to

[10

], a

n

d

tur

n

on

SV

3A,

SV3

B,

and

SV

3C. (

7

-se

gm

en

t d

isp

lay [

H

r]

[... 3

–

])

•

W

h

ile

th

e

o

u

td

oo

r u

n

it

is ru

nn

in

g,

che

ck th

e

t

e

mp

era

tu

re

ch

an

ge

on

th

e S

V

3

B

valve

seco

nd

ar

y.

–Fig

ur

e (4

)

ĺ

If

th

e te

m

p

er

a

tur

e

doe

s n

o

t b

e

co

me

h

ig

h

(

e

quiva

lent

to

ou

tdo

or

te

mp

er

at

ur

e)

, th

e

SV3

B va

lve

is clog

ge

d.

Re

place

th

e S

V

3B

valve

.

e)

C

heck the SV3E valve cloggin

g

R

e

set the

po

wer

Ļ

Co

nfi

rm

tha

t th

e S

V

3E

val

ve

is

tur

ne

d o

n

/

off

(so

un

d /

coi

l sur

fa

ce te

mp

er

at

ur

e r

isi

ng

) b

y

th

e "

v

al

ve f

o

rc

ed

op

en

/ cl

ose

fun

ction

" o

f th

e o

u

td

oo

r

un

it

.

Ļ

Sta

rt

the

coo

lin

g

or

he

atin

g te

st r

u

n.

Ļ

Afte

r

seve

ra

l mi

n

u

te

s of

th

e co

mp

re

ssor

o

p

e

ra

ti

o

n

, ch

eck th

e

pi

pe

tem

p

e

ratu

re

o

n

t

he

SV3

E va

lv

e e

x

it

. If

the

te

mp

era

tu

re

d

o

e

s

no

t c

h

an

g

e

or

is

e

q

uiv

a

le

n

t t

o

t

h

e

ou

td

o

o

r

te

mp

era

tu

re

, t

h

e

SV

3E

ma

y

b

e

c

log

ge

d.

–

F

igu

re

(5)

(R

e

fer

en

ce)

If th

e S

V

3

E

va

lv

e

is clog

ge

d,

all the

TK1

, TK2

, TK

3, TK

4 a

n

d

TK5

temp

e

ratu

re

s d

o

n

o

t

chan

ge

an

y more.

f)

C

heck the SV3F

va

lve clogging

•

S

e

t [

S

W

0

1

/

SW

02

/

SW

03]

to

[2

/

1

/ 3

]

(7

-se

gm

en

t

display

[Hr

][..

. ..

. .

..])

wh

ile

th

e

out

do

or

u

n

it is

ru

nn

ing,

an

d

the

n

pr

e

ss [SW

0

4] f

o

r 2

seco

nds

or

lon

g

er

.

•

S

e

t [S

W0

2]

to

[8],

an

d t

u

rn

o

n

S

V

3

C

, SV3

E,

an

d SV

3F.

(7

-s

egm

e

n

t d

isplay

[Hr]

[...

3 C])

•

W

h

ile

th

e

o

u

td

oo

r u

n

it

is ru

nn

in

g,

che

ck th

e

t

e

mp

era

tu

re

ch

an

ge

on

th

e S

V

3

F va

lve se

con

d

a

ry.

–F

igu

re

(3)

ĺ

If

th

e te

m

p

er

a

tur

e

doe

s n

o

t b

e

co

me

h

ig

h

(

e

quiva

lent

to

ou

tdo

or

te

mp

er

at

ur

e)

, th

e

SV3

F valve

is clogg

ed

.

Re

place

th

e S

V

3F va

lve.

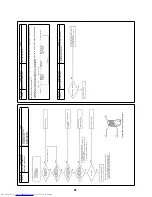

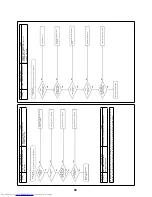

(*2

)Check th

e cl

ogg

ing of th

e

o

il sepa

rator

o

il return circuit

a

nd SV3D.

a)

O

il r

e

turn c

irc

uit

•

W

h

ile

t

h

e

o

u

td

oo

r u

n

it is ru

nn

in

g, che

ck t

h

e

te

mp

era

tur

e

o

n

the

oil

r

e

tu

rn cir

cuit (Ca

p

illa

ry seco

nd

a

ry).–Fi

gu

re

(

6

)

ĺ

If

the

temp

e

ratu

re

i

s

l

o

w (e

qu

iva

le

nt t

o

ou

tdo

or

t

e

mp

er

atur

e)

, th

e stra

ine

r o

r cap

illa

ry of the

oil

r

e

tu

rn

cir

cuit is

cl

o

gge

d.

R

epl

a

c

e t

he

clo

gg

ed

com

po

ne

nt.

b)

C

heck the SV3D

valve clogging

•

S

e

t [

S

W

0

1

/

SW

02

/

SW

03]

to

[2

/

1

/ 3

]

(7

-se

gm

en

t

display

[Hr

][..

. ..

. .

..])

wh

ile

th

e

out

do

or

u

n

it is

ru

nn

ing,

an

d

the

n

pr

e

ss [SW

0

4] f

o

r 2

seco

nds

or

lon

g

er

.

•

S

e

t [S

W0

2]

to

[9],

an

d t

u

rn

o

n

t

h

e

SV3

D valve

(

7

-s

eg

me

nt

displa

y [Hr

][...

3 d

])

•

If

th

e tem

pe

ra

tu

re

on

t

h

e va

lve

se

con

d

a

ry is lo

w or

d

o

e

s n

o

t cha

ng

e

, the

val

ve, cap

illa

ry, or

stra

in

er

i

s

cl

og

ge

d. –

Figu

re

(7)

R

e

p

lace

the

cl

og

ged

co

mp

on

ent

.

(*3)Ch

eck the

valve

of al

l t

he

outdo

or un

its in

the sa

me

li

ne

(Pe

rfo

rmed

on

ly i

n

the

outdoor unit link

age system

)

a)

Check the SV3A va

lve clogging

•

S

et [SW

0

1

/

SW

02

/

SW

03

] to [2 /

1

/ 3]

(

7

-s

eg

me

nt

disp

la

y

[H

r]

[... ... ...]

) while the

ou

td

oor

unit is

ru

n

n

ing

, and

th

en

p

ress [

S

W

0

4]

for

2

sec

ond

s or

lo

nge

r.

•

S

et

[SW

02

] to

[6

], a

n

d

tur

n

on

SV

3A.

(7

-s

egm

e

n

t

display

[Hr]

[...

3 A

])

•

If th

e t

e

m

p

e

ra

tur

e

on

th

e va

lve

se

cond

ar

y is lo

w

or

do

es n

o

t cha

nge

, t

he

valve

or

clack va

lve m

a

y be

clog

ged

. –

Figu

re

(1)

b)

Check the SV3C valve clo

gging

•

S

et [SW

0

1

/

SW

02

/

SW

03

] to [2 /

1

/ 3]

(

7

-s

eg

me

nt

disp

la

y

[H

r]

[... ... ...]

) while the

ou

td

oor

unit is

ru

n

n

ing

, and

th

en

p

ress [

S

W

0

4]

for

2

sec

ond

s or

lo

nge

r.

•

S

et

[SW

02

] to

[8

], a

n

d

turn

on

SV

3C. (7-se

g

men

t disp

lay [Hr][.

.. 3

C])

•

If t

h

e

tem

p

e

ratu

re

o

n

the

valve

se

cond

ar

y d

o

e

s

n

o

t

chan

ge

(

ri

se

),

th

e

valve

or

str

a

in

e

r m

a

y be

clog

ge

d.

–Figu

re

(

2

)

(*4)

a)

Check the oil circuit cloggin

g

•

O

pe

ra

te

the

ou

tdo

or

u

n

it. (

O

p

e

ra

te

a

ll

the

com

pr

e

ssor

s in t

h

e

un

it

.)

•

A

ft

e

r

o

p

era

ti

n

g

f

o

r

1

0

mi

nu

te

s

or

lon

ge

r,

c

o

n

firm

t

h

at

t

h

e

te

mp

er

at

u

res

o

f t

h

e TK

1,

TK

2,

an

d TK

3

s

e

ns

o

rs

a

n

d

oil

c

ir

c

ui

t (Fi

g

u

re

(

8

))

h

a

ve

be

com

e h

igh

.

(Ap

p

roxi

mat

e

gu

ide

)

TK

1,

TK2,

TK3

= Td

1,

Td2,

Td3

te

mp

er

at

ur

e –

10

to

30

°C

O

il

cir

cu

it

: H

ig

h

e

r th

an

sucti

o

n

te

m

per

a

tur

e

or

ou

tdo

or

te

m

per

a

tur

e

•

If

t

h

e

te

mp

er

at

ur

e

is lo

w,

t

h

e

clo

g

g

in

g

of

ca

pil

lar

y

,

str

a

in

e

r,

o

r d

ist

rib

ut

e

r,

or

t

h

e

cla

ck va

lve

op

er

at

io

n

err

or

ma

y ha

ve

o

ccurred

.

Fix th

e e

rro

r.

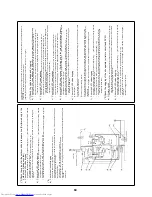

Cl

a

c

k

v

a

lv

e

Hig

h-

pr

ess

u

re

s

ens

or

Oi

l sepa

rat

or

Check

va

lv

e

Ch

eck

va

lve

Hi

gh-

pres

sure

SW

Hi

gh-

pr

e

ssu

re

SW

C

h

eck

va

lve

Chec

k v

a

lv

e

Co

m

pr

esso

r

1

(Inv

er

te

r)

Co

m

pre

sso

r

2

(In

vert

er

)

Oi

l heade

r

Dis

tr

ibu

ter

Check val

ve

Che

ck val

ve

(6)

(7)

(2)

(5)

(8)

(1)

(4

)

(8

)

Содержание MD-VNK802HEXE

Страница 120: ...118 11Owner s Manual Excerpt ...

Страница 137: ...135 12Installation Manual Excerpt ...