67

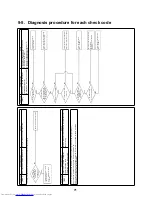

P10

P10

Detect indoor

addresses

Indoor

Indoor overflow

error

All stopped

• The float switch has worked.

• The float switch was broken, or

the connector was disconnected.

• Check the float switch connector.

• Check the drain pump

operations.

• Check the drain pump circuit.

• Check the drain pipe clogging.

• Check the indoor PC board error.

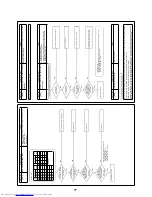

P13

P13

–

I/F

Outdoor

compressor

liquid

compression

error

All stopped

<Cooling>

A high pressure value was detected

in the stopped terminal unit while

the system is performing the cooling

operation.

<Heating>

The PMV 1 and 2 opening

continues being 100p or lower while

the system is performing the

heating operation and the outdoor

PMV is performing the SH control.

• Check the all-closing operations

of the outdoor PMV (1, 2, 4).

• Check the Pd and Ps sensor

error.

• Check the gas balance circuit

(SV2) clogging.

• Check the balance pipe clogging.

• Check the SV3B circuit clogging.

• Check the outdoor PC board (I/F)

error.

• Check the clogging of the oil

separator oil return circuit

capillary.

• Check the check valve leakage in

the discharge area.

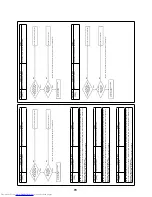

P15

P15

01: TS condition

I/F

Gas leak

detection

(TS1 condition)

All stopped

Protective stop (performed when

the intake temperature is over the

judgment criterion for 10 minutes) is

repeated 4 times or more.

<TS error judgment criteria>

Cool: 60 °C or higher

Heat: 40 °C or higher

• Check the refrigerant shortage.

• Open and check the outdoor

service valve. (Gas, Liquid)

• Check the outdoor PMV clogging

(PMV1, 2).

• Check the TS1 sensor resistant

characteristics.

• Check the four-way valve error.

• Check the SV4 circuit.

02: TD condition

I/F

Gas leak

detection

(TD condition)

All stopped

Protective stop (performed when

the compressor is running in low

frequency and the discharge

temperature TD1, TD2, or TD3 is

over 108 °C for 10 minutes) is

repeated 4 times or more.

• Check the refrigerant shortage.

• Check the outdoor PMV clogging

(PMV1, 2).

• Check the TD1, TD2, or TD3

sensor resistant characteristics.

• Check the indoor filter clogging.

• Check the pipe clogging.

• Check the SV4 circuit (valve leak,

coil misinstallation).

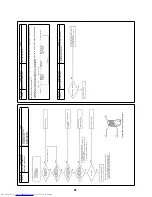

P17

P17

–

I/F

Discharge

temperature

TD2 error

All stopped

The discharge temperature (TD2)

exceeded 115 °C.

• Open and check the outdoor

service valve. (Gas, Liquid)

• Check the outdoor PMV clogging

(PMV1, 2, 4).

• Check the TD2 sensor resistant

characteristics.

• Check the four-way valve error.

• Check the SV4 circuit leakage.

• Check the SV4 circuit.

(SV41 / SV42 / SV43 miswiring)

P18

P18

–

I/F

Discharge

temperature

TD3 error

All stopped

The discharge temperature (TD3)

exceeded 115 °C.

• Open and check the outdoor

service valve. (Gas, Liquid)

• Check the outdoor PMV clogging

(PMV1, 2, 4).

• Check the TD3 sensor resistant

characteristics.

• Check the four-way valve error.

• Check the SV4 circuit leakage.

• Check the SV4 circuit.

(SV41 / SV42 / SV43 miswiring)

P19

P19

Detected outdoor

unit No.

I/F

Four-way valve

reverse error

All stopped

A refrigerant cycling error was

detected during heating.

• Check the four-way valve error.

• Check the four-way valve coil

error and connector connection.

• Check the TS1 and TE1 sensor

resistant characteristics.

• Check the Pd, Ps pressure

sensor error output voltage

characteristics.

• Check the misconnection of the

TE1, TL sensor.

Check code

Location

of

detection

Check code

name

System status

Error detection conditions

Items to check (locations)

Local

remote

controller

7-segment display of

outdoor unit

Check

code

Sub code

Содержание MD-VNK802HEXE

Страница 120: ...118 11Owner s Manual Excerpt ...

Страница 137: ...135 12Installation Manual Excerpt ...