SECTION 23: ACCESSORIES

4

DOB 2490-2789 | X3-45 Commuter PA1605 Maintenance Manual (Final Version – Rev.2 April 2016)

CAUTION

Do not attempt to manually move the wiper

arms to make wiper blade sweep adjustments

as damage to the wiper linkage or motor may

occur. If it is necessary to adjust the sweep of

blades, remove the arms and make

adjustment by positioning the arms using

serration on the wiper arm pivot shafts.

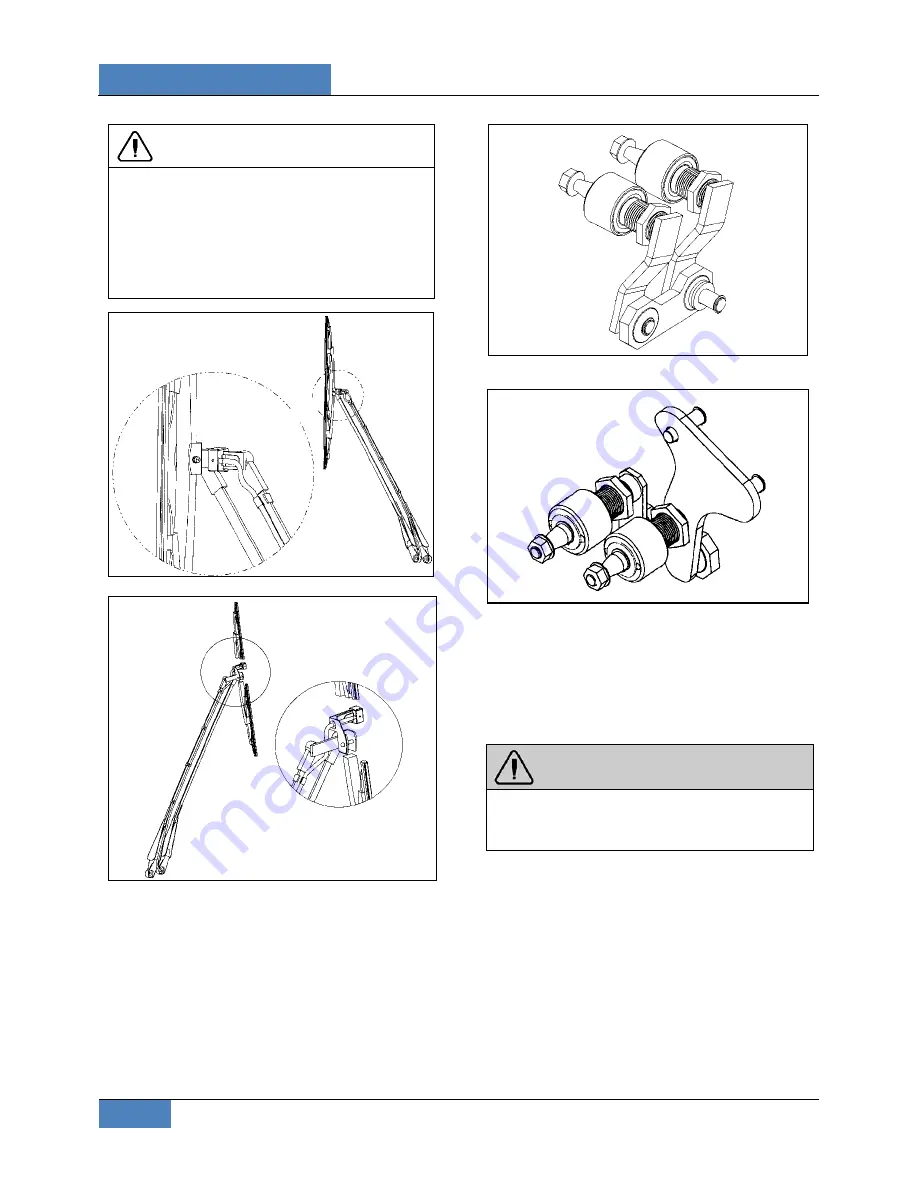

FIGURE 7: WINDSHIELD WIPER (MOTOR SIDE)

23329

FIGURE 8: WINDSHIELD WIPER (DRIVER SIDE)

23328

3. When the final position is found, tighten the

wiper arm nuts to 22 Ft-lbs (30 Nm). Wait 30

minutes and tighten again to 22 Ft-lbs.

4. Lower the protective cover.

5. Connect the windshield washer tubing at the

base of the wiper arm.

6. Check the adjustment on a wet windshield.

FIGURE 9: DRIVING MECHANISM (DRIVER SIDE)

23284

FIGURE 10: DRIVING MECHANISM (MOTOR SIDE)

23285

3.3

WINDSHIELD WIPER MOTOR

3.3.1

Windshield Wiper Motor Replacement

The windshield wiper motor is located at lower

front of the vehicle, behind the defroster panel.

Refer to figure 6 for motor location.

WARNING

Park vehicle safely, apply parking brake, stop

engine and set battery master switch to the

‘’OFF’’ position prior to working on the vehicle.

1. Remove the Phillips-head screws retaining

the defroster panels, and remove panels.

2. Disconnect wiring connector from the

windshield wiper motor.

3. Loosen clamping screw retaining the lever at

the end of the motor driving shaft.

4. Remove the three bolts holding the motor to

the steel plate.

5. Remove the windshield wiper motor

(Prevost #800328), reverse removal

procedure to reinstall.

Содержание X3-45 COMMUTER

Страница 4: ......

Страница 20: ......

Страница 50: ......

Страница 82: ......

Страница 198: ......

Страница 202: ......

Страница 212: ......

Страница 232: ......

Страница 270: ......

Страница 304: ......

Страница 322: ......

Страница 351: ...SECTION 16 SUSPENSION DOB 2490 2789 X3 45 Commuter PA1605 Maintenance Manual Section 16 revised April 2019 9...

Страница 352: ...SECTION 16 SUSPENSION 10 DOB 2490 2789 X3 45 Commuter PA1605 Maintenance Manual Section 16 revised April 2019...

Страница 370: ......

Страница 474: ......

Страница 542: ......