SECTION 09: PROPELLER SHAFT

10

DOB 2490-2789 | X3-45 Commuter PA1605 Maintenance Manual (Final Version – Rev.2 April 2016)

FIGURE 20: RAISED METAL OR FRETTING CAN BE

REMOVED FROM YOKE CROSS HOLES WITH A FINE-

TOOTHED FILE

4.3

REMOVAL PROCEDURE FOR SLIP

MEMBER BOOT

1. It is imperative to mark all mating

components of the propeller shaft. Mark the

propeller shaft with a marking stick, paint

marker or other legible marking device.

2. Remove and discard both boot clamps.

Clamps may be separated using a chisel to

disengage locking hooks. DO NOT reuse

clamps.

FIGURE 21: BOOT CLAMP

3. Completely collapse the boot toward the

yoke shaft to expose weld ring and spline

sleeve area. Wipe weld ring and spline

sleeve areas clean.

4. Remove the yoke shaft and boot from the

spline sleeve. Discard boot.

5. Inspect the yoke shaft spline surface for

damage. If the splines are damaged,

missing or twisted, or any Glidecote is

missing, complete propeller shaft

replacement is necessary.

6. Inspect the spline sleeve for damage. If the

splines are damaged, missing or twisted,

complete propeller shaft replacement is

necessary.

7. Inspect the entire slip assembly for

contaminants. If the slip assembly shows

evidence of rust or the lube is severely

contaminated, complete propeller shaft

replacement is necessary.

5. INSTALLATION

WARNING

Read “Spicer Life Series Driveshaft Installation

Warnings and Cautions” in

Spicer

Driveshaft’s Service Manual DSSM-0100.

5.1

SLIP MEMBER AND BOOT

INSTALLATION

1. Clean ALL grease from yoke shaft and

spline sleeve. Make sure grease-cutting

solvent does not intrude into the tube

through the vent hole in the spline sleeve

plug. Be sure the phasing marks made

during disassembly are not removed.

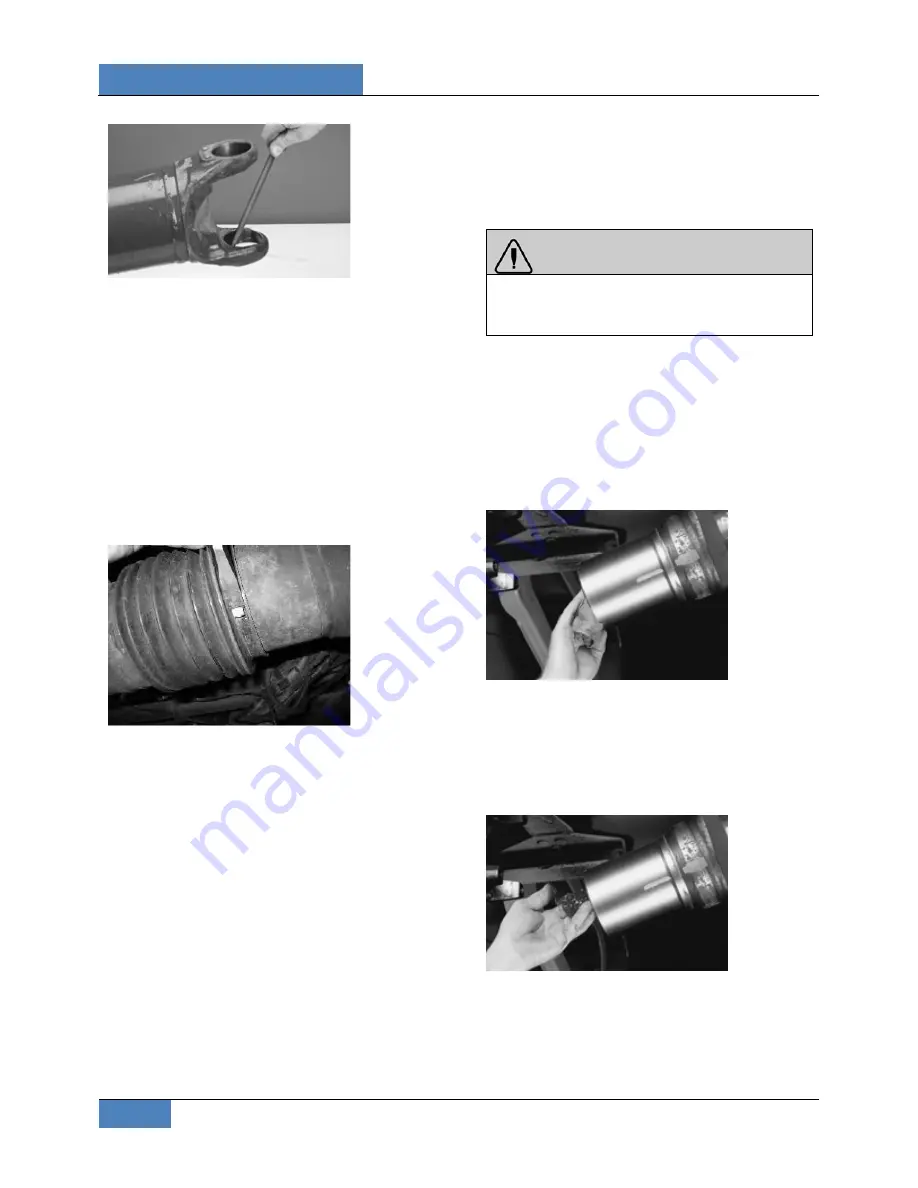

FIGURE 22: CLEAN GREASE FROM SPLINE SLEEVE

2. After all traces of grease and cutting solvent

have been removed from the yoke shaft and

spline sleeve, apply half of the grease

provided to the yoke shaft splines and the

other half to the spline sleeve, cover the

entire splined surface.

FIGURE 23: APPLY GREASE

3. Measure and place a mark 2.25 inches (55-

60mm) from yoke shaft shoulder with a

marking stick, paint marker or other legible

marking device.

Содержание X3-45 COMMUTER

Страница 4: ......

Страница 20: ......

Страница 50: ......

Страница 82: ......

Страница 198: ......

Страница 202: ......

Страница 212: ......

Страница 232: ......

Страница 270: ......

Страница 304: ......

Страница 322: ......

Страница 351: ...SECTION 16 SUSPENSION DOB 2490 2789 X3 45 Commuter PA1605 Maintenance Manual Section 16 revised April 2019 9...

Страница 352: ...SECTION 16 SUSPENSION 10 DOB 2490 2789 X3 45 Commuter PA1605 Maintenance Manual Section 16 revised April 2019...

Страница 370: ......

Страница 474: ......

Страница 542: ......