09/2007

4-4

Phaser 8860/8860MFP Service Manual

Disassembly Overview

Initial Issue

Repairs and Adjustments

Fastener Types

CAUTION

Screws in plastic are torqued to 12 in. lbs., metal to 15 in lbs., unless otherwise specified. The

screws for the Printhead Restraints should be torqued to 6 in. lbs. Irreversible damage can

result from over tightening the screws into plastic parts. Always use the correct type and size

screw. Using the wrong screw can damage tapped holes.

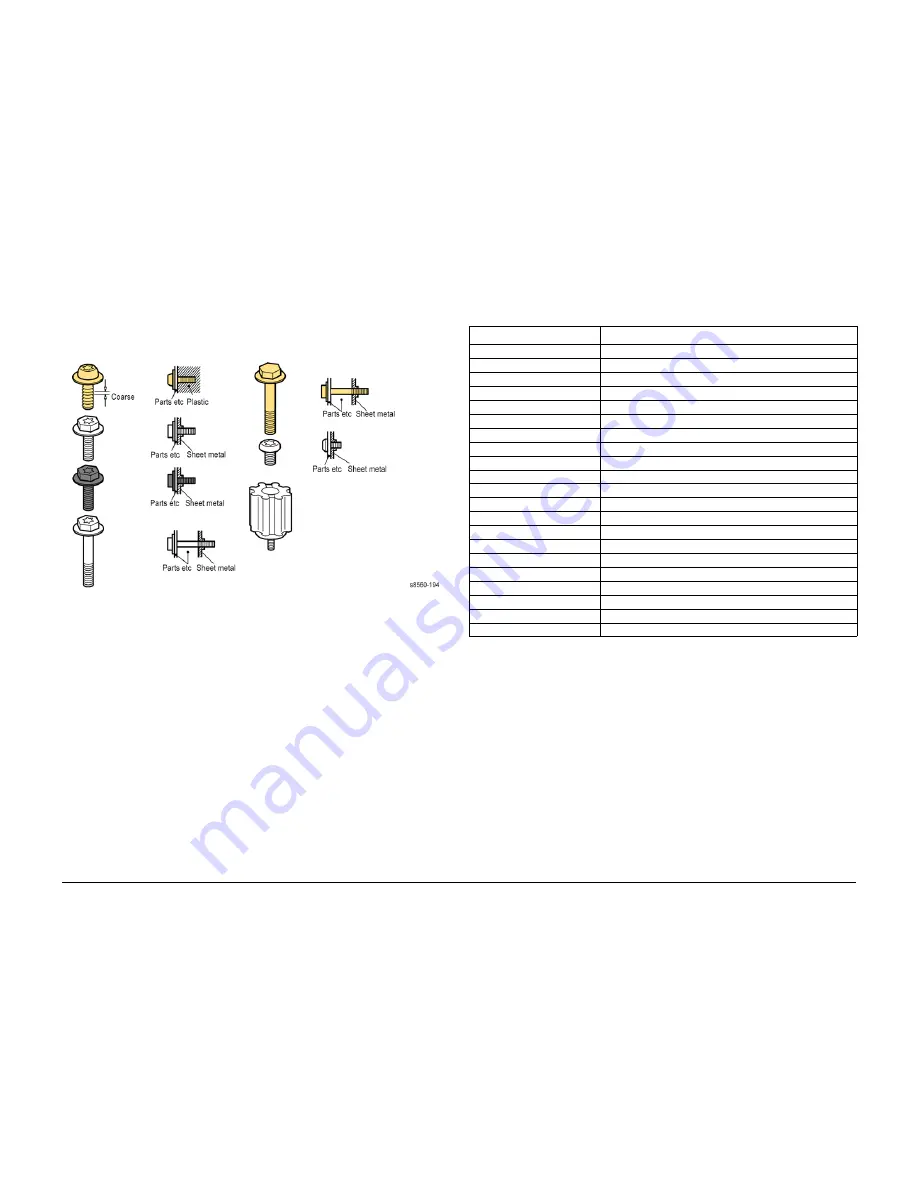

Figure 2 Fastener Types

Follow these guidlines for fasteners in this product:

•

Always use the correct type and size screw; coarse thread, brass-colored screws into

plastic and fine thread, silver-colored screws into metal.

•

Using the wrong screw can damage tapped holes. This applies to the yellow reverse-

threaded screws on the Drum.

•

Do not use excessive force to remove or install either a screw or a printer part. If using a

power driver to install a screw into plastic, start the screw by hand.

•

If you strip out threads in the plastic chassis, a silver-blue-tinted thread repair screw

(included in the hardware kit) can be used to correct the problem.

•

If you remove a silver-blue-tinted thread repair screw during disassembly, replace the

screw the same location or additional damage to the printer will occur.

Fasteners used in the product appear in

Figure 2

. Removal procedures include dimensional

specifications for screws being removed.

CAUTION

Many parts are secured by plastic tabs or hooks. Do not over Flex or force these parts.

Recommended Tool Kit

Table 1

lists required and recommended tools used to service this and other similar products.

Table 1 Recommended Service Tools

Description

Detail

Torx Drivers Bits

T5, T8, T10, T15 (T20 P/N 003086600)

Phillips Drivers

Phillips # 2 and # 1 5.0 x 75 mm, 3.0 x 75 mm, 6.0 x 100 mm

Flathead Drivers

5.0 x 75 mm, 3.0 x 75 mm

Torque Screw Driver

Required for this system P/N 003082700

Hex Bit

2.5mm Hex Bit, T-20 P/N 003086600

Driver Extension

Small Channel lock Pliers

Needle Nose Pliers

Wire Cutters

Flashlight

Assorted Nut Drivers

Lint-Free Cloths

Cleaners

Multipurpose surface cleaner and Alcohol

ESD Strap

Nut Driver

5.5mm (magnetic) P/N 600T2123

Serial Adaptor Cable

600T80374

Network Cross-over cable

Tech

Scanner Calibration page P/N 109K01910

Toner Vac

Toner and general cleaning

Multimeter

Volts, Ohms, Current

Lubricant/Grease

Reolube P/N 070E00890

Summary of Contents for Phaser 8860

Page 1: ...705P01205 September 2007 Phaser 8860 8860MFP Service Documentation...

Page 4: ...09 2007 iv Phaser 8860 8860MFP Service Manual Initial Issue Introduction...

Page 28: ...09 2007 1 2 Phaser 8860 8860MFP Service Manual Initial Issue Service Call Procedures...

Page 34: ...09 2007 2 2 Phaser 8860 8860MFP Service Manual Initial Issue Error Messages and Codes...

Page 94: ...09 2007 3 2 Phaser 8860 8860MFP Service Manual Initial Issue Image Quality...

Page 126: ...09 2007 4 2 Phaser 8860 8860MFP Service Manual Initial Issue Repairs and Adjustments...

Page 208: ...09 2007 5 2 Phaser 8860 8860MFP Service Manual Initial Issue Parts List...

Page 222: ...09 2007 6 2 Phaser 8860 8860MFP Service Manual Initial Issue Diagnostics...

Page 274: ...09 2007 7 2 Phaser 8860 8860MFP Service Manual Initial Issue Wiring Data...

Page 294: ...09 2007 8 2 Phaser 8860 8860MFP Service Manual Initial Issue Theory of Operation...