09/2007

6-40

Phaser 8860/8860MFP Service Manual

Scanner Malfunction, Control Panel Malfunction

Initial Issue

Diagnostics

Scanner Malfunction

Scanhead Does Not Move

1.

Verify the scanhead shipping lock is in the “unlocked” position. Reboot the system.

2.

Is there power to the Scanner Assembly? Lift the DADF and verify the lamp is on. If so,

the Scanner Power Supply is operating correctly.

3.

Verify the Scanner Power Supply operation. See

Scanner Power Supply

.

4.

Replace the Scanner Assembly (

REP 1.0.11

).

Scanhead Motion Erratic

1.

Verify the scanhead shipping lock is in the “unlocked” position. Reboot the system.

2.

Run the Service Diagnostics Exercise Axis Motion test and observe Scanhead motion,

paying special attention to anything that could obstruct scanhead motion.

3.

Replace the Scanner Assembly (

REP 1.0.11

).

Scanner Lamp Does Not Turn On

1.

Is there power to the Scanner Assembly? Lift the DADF and verify the scanhead moves. If

so, the Scanner Power Supply is operating correctly.

2.

Check the Scanner Power Supply. See

Scanner Power Supply

.

3.

Replace the Scanner Assembly (

REP 1.0.11

).

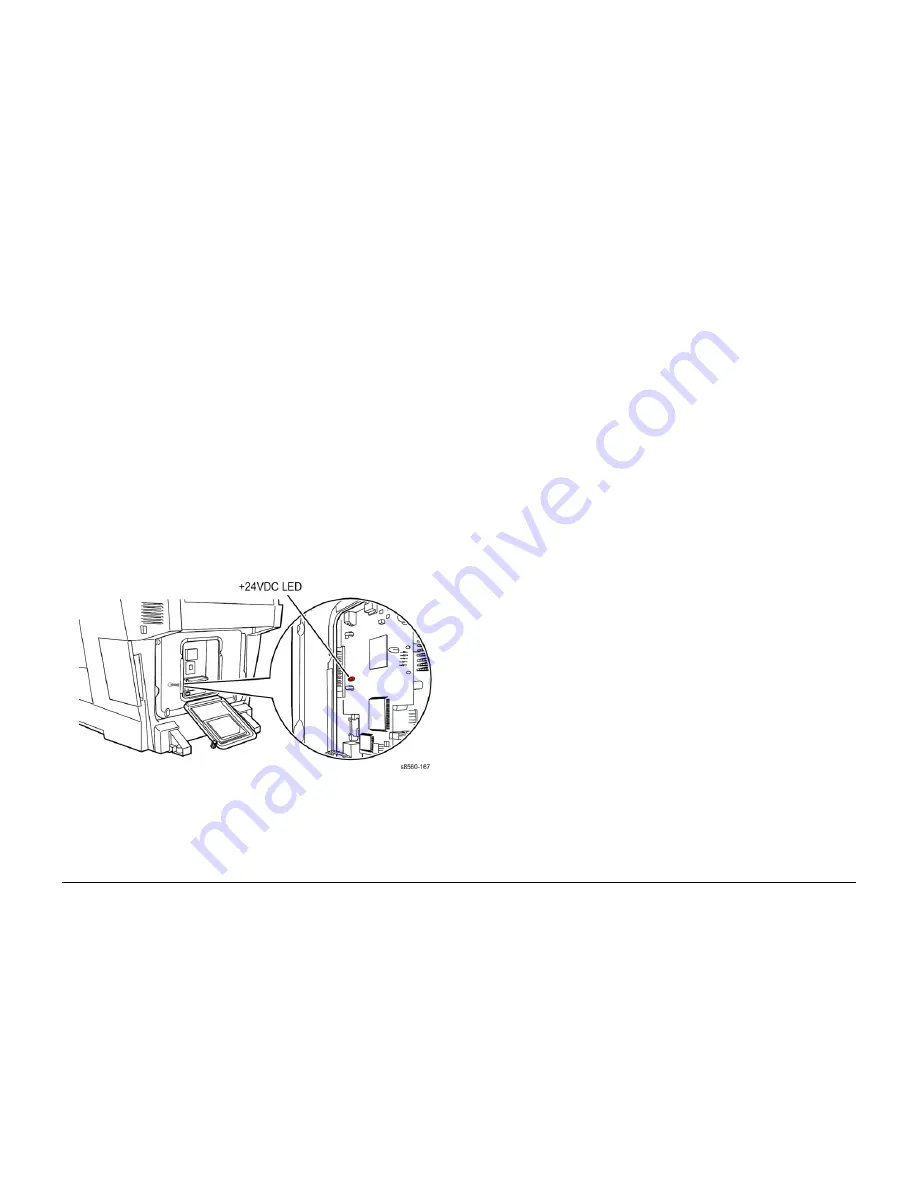

Scanner Power Supply

1.

Check the +24 VDC Status LED. If the LED is On, the Scanner Power Supply is opera-

tional. If the LED is blinking, there is a problem with the DADF, Scanner Power Supply or

Exit Module Control Board.

Figure 1 Scanner Power Supply 24 Volt Status LED

2.

If the LED is blinking, turn the system Off and disconnect the DADF. Restart the system. If

the LED is blinking, the DADF is not the problem.

3.

Disconnect the Scanner Assembly. Turn the system On, if the LED is still blinking, the

problem is not the Scanner Assembly. Replace the Scanner Power Supply (

REP 5.0.2

).

4.

If the +24 V Status LED is off, there could be a problem with the Scanner Power Supply or

the Electronics Module.

Control Panel Malfunction

Control Panel Not Responding

NOTE:

Make sure to connect the scanner cable properly to the Electronics Module.

1.

If the system is powered On and frozen, open then close the Front Door to see if the Con-

trol Panel responds.

2.

If system appears functional after operating the door, advise client that failure may have

been due to an ESD event. Thoroughly test system for any other problems.

3.

Skip the rest of this section if the system is functional, otherwise continue troubleshooting

4.

Reseat the Scanner Assembly connection to the Electronics Module.

5.

With Power Cord connected, touch the Electronics Module to discharge any static. ESD

damage may occur if static electricity is discharged to system electronics.

6.

Turn off system and wait 30 seconds for power supply capacitors to discharge. Damage to

circuits within the Electronics Module may occur if the power supply capacitors are not

allowed to fully discharge.

7.

Unplug power cord and remove system's covers. Use caution around motors, pulleys and

live AC connections when working with the system covers off.

8.

Examine system for loose grounding connections, especially the ground strap on the Y-

Axis motor. Eliminate the possibility of internally generated ESD from affecting system

9.

Plug in all cables removed during service. Trace through all service steps performed to

reattach any cables that were unplugged during troubleshooting.

10. Reassemble and retest the system.

Control Panel is Blank

A blank Control Panel indicates some portion of the chain of devices used to drive the LCD

may be defective. If the PS and PE LEDs are flashing a code, see

Power On Self Tests

. If no

error indication is available, use the following procedure to check the Control Panel.

1.

If the system is powered On, open then close the Front Door to see if the control panel

responds.

2.

If the system is functional after operating the door, advise client that failure may have

been due to an ESD event. Thoroughly test system for any other problems.

3.

Skip the rest of this section if the system now appears functional, otherwise continue trou-

bleshooting

4.

Reseat the Scanner Assembly connection to the Electronics Module.

5.

With power cord connected, touch the metal Electronics Module to discharge any static

electricity to prevent ESD damage to the system may occur if static electricity is dis-

charged to system electronics.

6.

Turn off system and wait 30 seconds for power supply capacitors to discharge. Damage to

circuits within the Electronics Module may occur if the power supply capacitors are not

allowed to fully discharge.

7.

Unplug the Power Cord and remove the Control Panel (

REP 1.0.9

). Check the Control

Panel connection (

P/J19

) to the Scanner Assembly.

8.

Examine system for loose grounding connections, especially the ground strap on the Y-

axis motor. Eliminate the possibility of internally generated ESD from affecting system

9.

Reassemble and retest the system.

10. Replace the Control Panel.

Summary of Contents for Phaser 8860

Page 1: ...705P01205 September 2007 Phaser 8860 8860MFP Service Documentation...

Page 4: ...09 2007 iv Phaser 8860 8860MFP Service Manual Initial Issue Introduction...

Page 28: ...09 2007 1 2 Phaser 8860 8860MFP Service Manual Initial Issue Service Call Procedures...

Page 34: ...09 2007 2 2 Phaser 8860 8860MFP Service Manual Initial Issue Error Messages and Codes...

Page 94: ...09 2007 3 2 Phaser 8860 8860MFP Service Manual Initial Issue Image Quality...

Page 126: ...09 2007 4 2 Phaser 8860 8860MFP Service Manual Initial Issue Repairs and Adjustments...

Page 208: ...09 2007 5 2 Phaser 8860 8860MFP Service Manual Initial Issue Parts List...

Page 222: ...09 2007 6 2 Phaser 8860 8860MFP Service Manual Initial Issue Diagnostics...

Page 274: ...09 2007 7 2 Phaser 8860 8860MFP Service Manual Initial Issue Wiring Data...

Page 294: ...09 2007 8 2 Phaser 8860 8860MFP Service Manual Initial Issue Theory of Operation...