Fault Conditions

MedWeld 4000 Operator’s Guide

Modified: 9/17/08

8 - 5

M-032116 Programs #T03300, #T02300 and #T02400

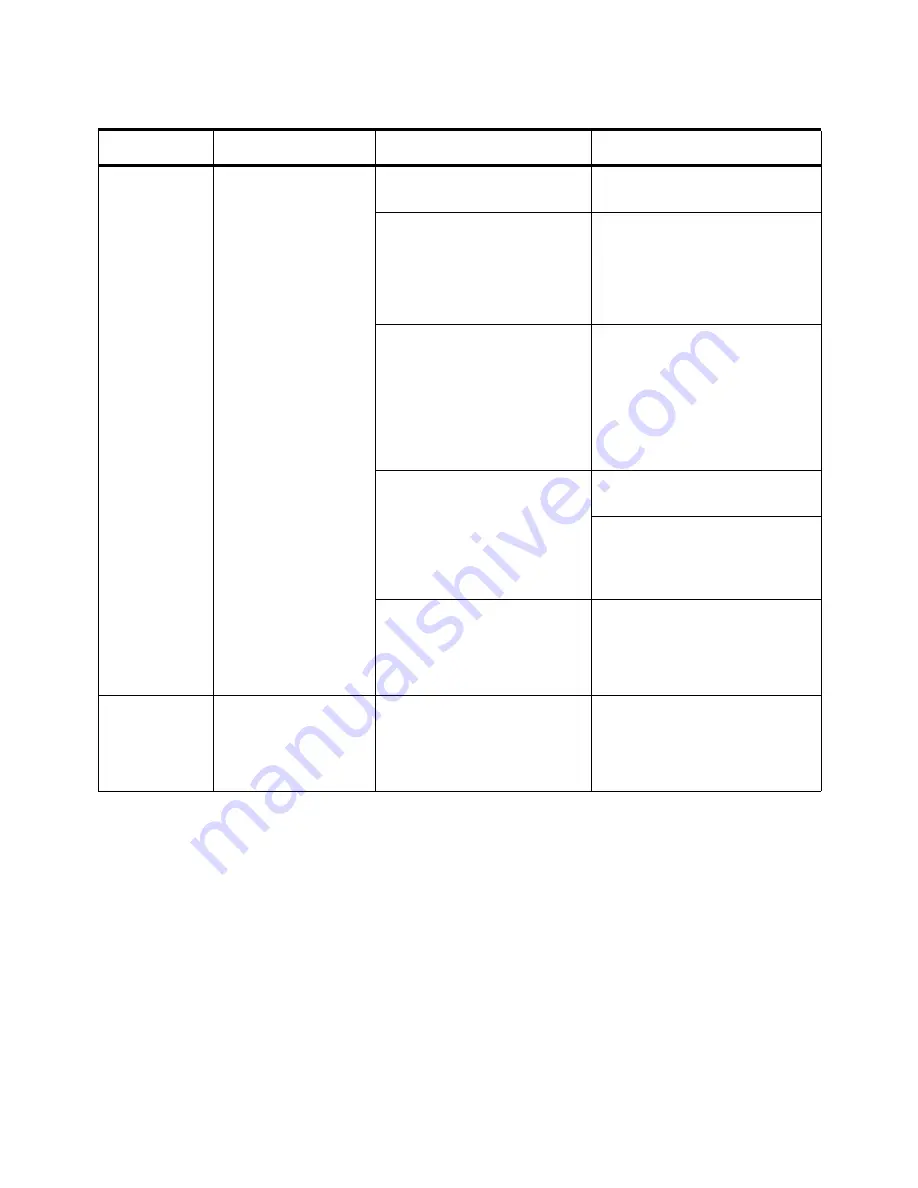

High Current

Limit

(See p. 5-3)

(Also

Secondary

Current Limit

when the

inverter is in

Secondary

Current firing

mode)

The control detected

that the current fired

during the weld

schedule exceeded

the high current limit.

(This could be the

limit in the setup

parameters OR set

by Function #76 in

the weld schedule.)

The limit is set too low.

Re-program high current limit

(Function #76).

Welder impedance is lower

than it was when the current

limit was set. The welder may

be drawing more current than

the originally-calculated

maximum.

Check for improper installation

of either a kickless cable or

shunt cable.

Pressure being maintained to

the tips changed during the

weld, so less pressure to the

welding spot was provided.

The weld processor will

compensate, and possibly

generate a HIGH CURRENT

LIMIT fault.

With a pressure gauge, verify

that constant pressure is being

maintained. Check for things

affecting pressure (such as

hoses binding in the weld gun

tooling, faulty or sticky solenoid

valves or slow-moving cylin-

ders.

Incorrect measurement of the

primary current. (Since both

the weld processor and the

firing card are involved in cur-

rent measurement, certain

failures on one of these cards

may cause this fault to occur.)

Check for loose wiring at the J3

connector on the firing card.

Secure the cable that runs

between the firing card and the

processor. Check for bad con-

nector. Replace as necessary.

Expulsion caused reduction

in the weld resistance. (This

may cause the current to

exceed the calculated

maximum.)

Adjust the schedule to reduce

expulsion while maintaining suf-

ficient current to provide a good

weld.

Inhibit

Initiation on

Fault

The weld sequence was

initiated with a fault present,

but the weld schedule would

not sequence due to a fault

condition.

Message

Explanation

Possible Cause

Remedy