Maintenance

3103

−

1/A1

Winterthur Gas & Diesel Ltd.

Crankshaft

Crank Deflection

−

Measure

Tools:

1 Crankshaft equipment (dial gauge)

94305

1.

General

It is sufficient to regularly measure the crank-web deflection in accordance with the

intervals given in the class rules. In the conditions that follow, it can become

necessary to measure the dimensions:

D

Important change of crank-web deflection results compared to the set of previous

results.

D

Temperature alarms of bearings, or damage to bearings.

D

After the main bearing shells are replaced and again after approximately

100 service hours.

D

If the ship has touched the sea bed.

In such conditions, it is recommended that you speak to Winterthur Gas & Diesel Ltd.

The crankshaft equipment (94305) is held between the crank webs in the center

punch marks. When the crankshaft turns, the change in distance between the crank

webs can be read from the dial gauge. This shows the distance the crank web has

opened or closed. The smaller the difference the better the crankshaft is aligned. But,

you must think about the function of the crankshaft equipment, ie the signs on the dial

gauge + (standard)

−

.

2.

Conditions

The conditions to measure crank-web deflection are as follows:

D

The indicator valves must be open.

D

The ship must be floating freely in the water as horizontal as possible.

D

The crankshaft must touch all the main bearings.

The conditions that follow will have an effect

when you do the procedure to measure the

crank-web deflection:

D

The engine is cold or at service

temperature.

D

The difference in temperature between

the lubricating oil sump tank and the

seawater.

D

The loaded condition of the ship (the

draught).

D

Strong sunshine.

It is recommended the you include these

data in the records.

3.

Procedure

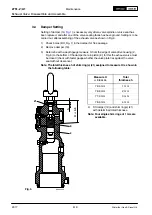

Note: During the procedure, the flywheel

) and pinion (2) of the

turning gear must turn in the

directions shown.

2017

Fig. 1

2

1

WCH03623

TURNING GEAR

ON EXHAUST

SIDE

Summary of Contents for X35-B

Page 12: ...Intentionally blank ...

Page 14: ...Intentionally blank ...

Page 16: ...Intentionally blank ...

Page 34: ...Intentionally blank ...

Page 58: ...Intentionally blank ...

Page 60: ...Maintenance 0352 1 A1 Winterthur Gas Diesel Ltd 2 6 WCH03791 2017 ...

Page 61: ...Maintenance 0352 1 A1 Winterthur Gas Diesel Ltd 3 6 WCH03791 2017 ...

Page 62: ...Maintenance 0352 1 A1 Winterthur Gas Diesel Ltd 4 6 WCH03791 2017 ...

Page 63: ...Maintenance 0352 1 A1 Winterthur Gas Diesel Ltd 5 6 WCH03791 2017 ...

Page 64: ...Maintenance 0352 1 A1 Winterthur Gas Diesel Ltd 6 6 WCH03791 2017 ...

Page 68: ...Intentionally blank ...

Page 72: ...Intentionally blank ...

Page 82: ...Intentionally blank ...

Page 85: ...Intentionally blank ...

Page 92: ...Intentionally blank ...

Page 96: ...Intentionally blank ...

Page 112: ...Intentionally blank ...

Page 120: ...Intentionally blank ...

Page 124: ...Intentionally blank ...

Page 138: ...Intentionally blank ...

Page 154: ...Intentionally blank ...

Page 168: ...Intentionally blank ...

Page 180: ...Intentionally blank ...

Page 182: ...Maintenance 2728 1 A1 Winterthur Gas Diesel Ltd 2 5 6 Lift housing from the valve spindle 4 ...

Page 186: ...Intentionally blank ...

Page 190: ......

Page 204: ...Intentionally blank ...

Page 211: ...Intentionally blank ...

Page 216: ...Intentionally blank ...

Page 224: ...Intentionally blank ...

Page 228: ......

Page 229: ...Intentionally blank ...

Page 264: ...Intentionally blank ...

Page 270: ...Intentionally blank ...

Page 280: ...Intentionally blank ...

Page 294: ...Intentionally blank ...

Page 298: ...Intentionally blank ...

Page 302: ...Intentionally blank ...

Page 318: ...Intentionally blank ...

Page 328: ...Intentionally blank ...

Page 344: ...Intentionally blank ...

Page 368: ...Intentionally blank ...

Page 374: ...Intentionally blank ...

Page 380: ...Intentionally blank ...

Page 396: ...Intentionally blank ...

Page 407: ...Intentionally blank ...

Page 426: ...Intentionally blank ...

Page 442: ...Intentionally blank ...

Page 444: ...Intentionally blank ...