Maintenance

1903

−

1/A1

Winterthur Gas & Diesel Ltd.

3.

Tie Rods

−

Replace

3.1

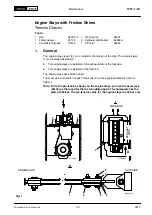

Preparation

Note: There are two tie rods at locations

a

−

a, b

−

b, c

−

c, e

−

e and f

−

f. There is

one tie rod at locations d

−

d and g

−

g

1) Remove the protection cover (1,

from the applicable tie rods (2).

2) Clean the surfaces of the intermediate

rings (4).

3) Connect the applicable equipment to the

double pre-tensioning jacks, refer to

.

4) Attach the two double pre-tensioner

jacks (94180) to the applicable two or

.

3.2

Removal

1) Apply a pressure of 1530 bar to the tie

.

2) Loosen the round nuts (3).

3) Release the pressure in the

pre-tensioning jacks (94180).

4) Remove the pre-tensioning jacks

(94180).

5) Use two round nuts screwed together to

loosen fully the tie rod (2).

6) Attach an M12 eye bolt to the tie

rod (2).

7) Attach the hook of the engine room

crane to the M12 eye bolt.

8) Operate the engine room crane to

remove the tie rod (2) from the cylinder

jacket (5).

3.3

Installation

1) Clean the top surfaces of the cylinder jacket (5).

2) Apply Molykote paste G to the bottom M42x3 thread of the tie rod (2).

3) Make sure that the intermediate ring (4) is installed.

4) Attach an M12 eye bolt to the tie rod (2).

5) Attach the hook of the engine room crane to the M12 eye bolt.

6) Operate the engine room crane to lift then lower the the tie rod (2) into the cylinder

jacket (5).

7) Remove the engine room crane and the M12 eye bolt.

8) Apply Molykote paste G to the top thread of the tie rod (2) and the opt surface of the

intermediate ring (4).

9) Attach the round nut (3) to the tie rod (2).

10) Tighten fully the tie rod (2).

11) Apply tension to the tie rod, refer to paragraph

.

2017

Tension Checks and Replacement Procedure

Fig. 2

3

2

5

4

I

1

WCH03622

3

5

I

II

WCH03622

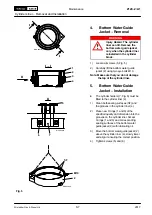

2-part Bush

II

Summary of Contents for X35-B

Page 12: ...Intentionally blank ...

Page 14: ...Intentionally blank ...

Page 16: ...Intentionally blank ...

Page 34: ...Intentionally blank ...

Page 58: ...Intentionally blank ...

Page 60: ...Maintenance 0352 1 A1 Winterthur Gas Diesel Ltd 2 6 WCH03791 2017 ...

Page 61: ...Maintenance 0352 1 A1 Winterthur Gas Diesel Ltd 3 6 WCH03791 2017 ...

Page 62: ...Maintenance 0352 1 A1 Winterthur Gas Diesel Ltd 4 6 WCH03791 2017 ...

Page 63: ...Maintenance 0352 1 A1 Winterthur Gas Diesel Ltd 5 6 WCH03791 2017 ...

Page 64: ...Maintenance 0352 1 A1 Winterthur Gas Diesel Ltd 6 6 WCH03791 2017 ...

Page 68: ...Intentionally blank ...

Page 72: ...Intentionally blank ...

Page 82: ...Intentionally blank ...

Page 85: ...Intentionally blank ...

Page 92: ...Intentionally blank ...

Page 96: ...Intentionally blank ...

Page 112: ...Intentionally blank ...

Page 120: ...Intentionally blank ...

Page 124: ...Intentionally blank ...

Page 138: ...Intentionally blank ...

Page 154: ...Intentionally blank ...

Page 168: ...Intentionally blank ...

Page 180: ...Intentionally blank ...

Page 182: ...Maintenance 2728 1 A1 Winterthur Gas Diesel Ltd 2 5 6 Lift housing from the valve spindle 4 ...

Page 186: ...Intentionally blank ...

Page 190: ......

Page 204: ...Intentionally blank ...

Page 211: ...Intentionally blank ...

Page 216: ...Intentionally blank ...

Page 224: ...Intentionally blank ...

Page 228: ......

Page 229: ...Intentionally blank ...

Page 264: ...Intentionally blank ...

Page 270: ...Intentionally blank ...

Page 280: ...Intentionally blank ...

Page 294: ...Intentionally blank ...

Page 298: ...Intentionally blank ...

Page 302: ...Intentionally blank ...

Page 318: ...Intentionally blank ...

Page 328: ...Intentionally blank ...

Page 344: ...Intentionally blank ...

Page 368: ...Intentionally blank ...

Page 374: ...Intentionally blank ...

Page 380: ...Intentionally blank ...

Page 396: ...Intentionally blank ...

Page 407: ...Intentionally blank ...

Page 426: ...Intentionally blank ...

Page 442: ...Intentionally blank ...

Page 444: ...Intentionally blank ...