SINUS PENTA

PROGRAMMING GUIDE

108

/

486

13.2.

Scaling Analog Inputs REF, AIN1, AIN2

NOTE

Please refer to the Sinus Penta’s Installation Guide for hardware details about analog inputs.

Three analog inputs are available: REF, AIN1, AIN2.

They can be voltage inputs or current inputs (switching is made possible through hardware Dip–Switch

SW1

and

software parameters) and are bipolar analog inputs (–10V

÷

+10V or –20mA

÷

+20mA).

REF

input is single–ended;

AIN1

and

AIN2

inputs are differential inputs.

Factory setting is as follows: the

main speed reference

is given by

REF

analog input,

0V

÷

+10V

mode; only motor 1 is

active. Its max. speed and min. speed parameters are

C088

=

1500

rpm and

C029

=

0

rpm respectively.

For the 3 analog inputs, parameters

P050

÷

P064

allow setting the type of signal to be acquired, offset compensation (if

any), scaling to obtain a speed reference or a torque reference, the signal filtering time constant.

Parameter

P053

sets the offset of the input analog signal (if

P053

=0 offset is zero), while parameter

P054

defines the

filtering time constant (factory setting: P054 = 5ms).

Type of input: for each analog input, Dip–Switch

SW1

allows setting the acquisition method of the input signal: voltage

signal or current signal.

The voltage signal can be bipolar (–

10V

÷

+10V

) or unipolar (

0V

÷

+10V

).

The current signal can be bipolar (

–20mA

÷

+20mA

), unipolar (

0mA

÷

+20mA

)

or can have a minimum offset (

4mA

÷

20mA

).

The user will set each analog input mode in parameters

P050

,

P055

,

P060

.

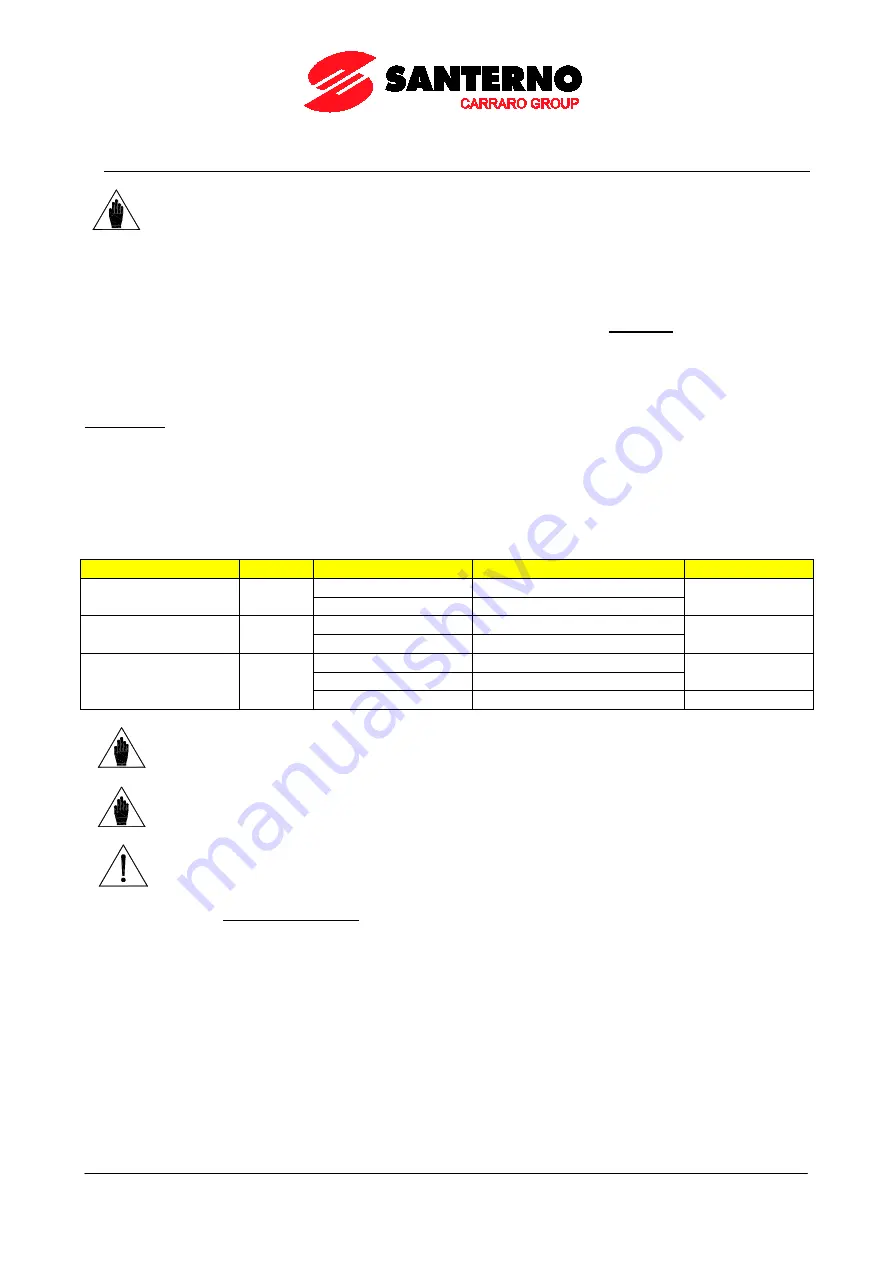

Table 26: Analog Input Hardware Mode

Type / Terminals

Name

Type

Dip–Switch

Parameter

Single-ended input/ 1,2

REF

±10V Input

SW1–1 off

P050

0–20mA Input

SW1–1 on

Differential input / 5,6

AIN1

±10V Input

SW1–2 off

P055

0–20mA Input

SW1–2 on

Differential input / 7,8

AIN2

±10V Input

SW1–3 off, SW1–4 5 off

P060

0–20mA Input

SW1–3 on, SW1–4 5 off

PTC Input

SW1–3 off, SW1–4 5 on

See note

NOTE

If AIN2 input is configured as PTC, refer to the MOTOR THERMAL PROTECTION MENU to

select the proper parameters. Its measures are no longer valid.

NOTE

Configurations different from the ones stated in the table above are not allowed.

CAUTION

For each analog input (REF, AIN1, AIN2), make sure that the “mode” parameter setting

(

P050

,

P055

,

P060

) matches with the setting of the relevant SW1 Dip–Switches.

Scaling is obtained by setting the parameters relating to the

linear function for the conversion

from the value read by

the analog input to the corresponding speed/torque reference value.

The

conversion function

is a

straight line

passing through

2 points

in

Cartesian coordinates

having the values read

by the analog input in the X-axis, and the speed/torque reference values multiplied by the reference percentage

parameters in the Y-axis.

Each point

is detected through its

two coordinates

.

The ordinates of the two points are the following:

the value of

Speed_Min

(or

Trq_Min

for the torque reference) multiplied by the percentage set through

P051a

/

P056a

/

P061a/P071a/P073a

for the

first point

; the value of

Speed_Max

(or

Trq_Max

for the torque reference)

multiplied by the percentage set through

P052a

/

P057a

/

P062a/P072a/P074a

for the

second point

.