[11 - 4]

CHAPTER 11. MASTER DISPOSAL SECTION

Disassembly

1.

Removing the 1st Master Disposal Unit

(1)

Remove the master disposal box.

(2)

Remove the master disposal cover. (Five M4 x 6 screws)

(3)

Disconnect the three connectors and remove the two mounting screws (M4 x 8). Since the master

disposal unit protrudes from the front, pull out and remove from the rear first.

* Detach the wire harness from the wire harness clamp with the rear end of the unit pulled out slightly.

[Precautions for Reassembly]

Insert the flat section of the master disposal unit frame plate into the gap between the master disposal

stay and the master disposal unit guide.

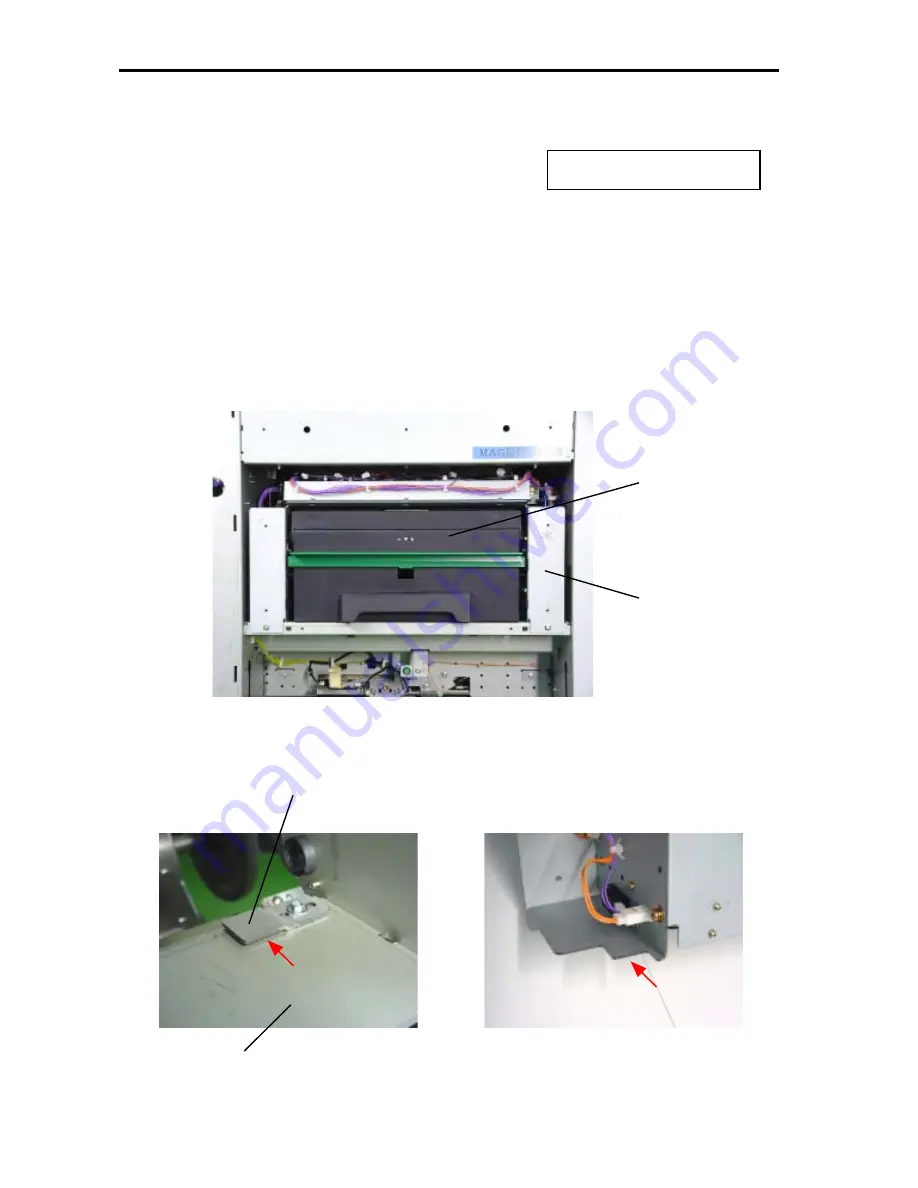

< REAR >

< FRONT >

Master disposal box

Master disposal unit

Master disposal unit guide

Master disposal stay

Flat section on master disposal

unit frame plate

P1101

P1102

P1103

< Master disposal unit guide >

Refer to page 11-18 for removing

2nd Master Disposal Unit.

Summary of Contents for V8000 Series

Page 30: ... 1 19 CHAPTER 1 MAINTENANCE 4 Removing Exterior Covers Rear cover Rear cover P0112 ...

Page 31: ... 1 20 CHAPTER 1 MAINTENANCE Front doors L R Front door R Front door L P0113 P0114 P0115 P0116 ...

Page 42: ... 2 6 CHAPTER 2 MACHINE OVERVIEW MEMO ...

Page 54: ... 3 12 CHAPTER 3 MAIN DRIVE SECTION MEMO ...

Page 78: ... 4 24 CHAPTER 4 FIRST PAPER FEED SECTION MEMO ...

Page 92: ... 5 14 CHAPTER 5 SECOND PAPER FEED SECTION MEMO ...

Page 112: ... 6 20 CHAPTER 6 PAPER DRUM SECTION MEMO ...

Page 170: ... 8 44 CHAPTER 8 PRINT DRUM SECTION MEMO ...

Page 178: ... 9 8 CHAPTER 9 VERTICAL PRINT POSITION SECTION MEMO ...

Page 206: ... 11 20 CHAPTER 11 MASTER DISPOSAL SECTION MEMO ...

Page 209: ... 12 3 CHAPTER 12 FB ORIGINAL SCANNING SECTION MEMO ...

Page 263: ... 15 1 CHAPTER 15 TIMING CHARTS Contents This chapter is not completed ...

Page 333: ... 18 4 CHAPTER 18 FUNCTIONS MEMO ...

Page 355: ... 20 18 CHAPTER 20 PRINTED CIRCUIT BOARDS MEMO ...