NewFEIMAS

Refer to Revision Record on page 2.

T.Anzai

Nov. 20, 2008

K.Okada

Rev

04

03

PAGE

53

/

138

PFU LIMITED

P1PA03334-B30X/6

Refer to Revision Record on page 2.

T.Anzai

July 7, 2008

K.Okada

Refer to Revision Record on page 2.

K.Okada

K.Okada

DESCRIPTION

CHECK

DATE

T.Anzai

APPR.

K.Okada

K.Okada

Aug.19, 2005

DESIG

N

DESIG

.

CUST.

I.Fujioka

I.Fujioka

T.Anzai

CHECK

fi-5530C/fi-5530C2

IMAGE SCANNER

MAINTENANCE MANUAL

APPR.

TITLE

DRAW.

No.

Feb.23, 2007

05

Section 3-3-9

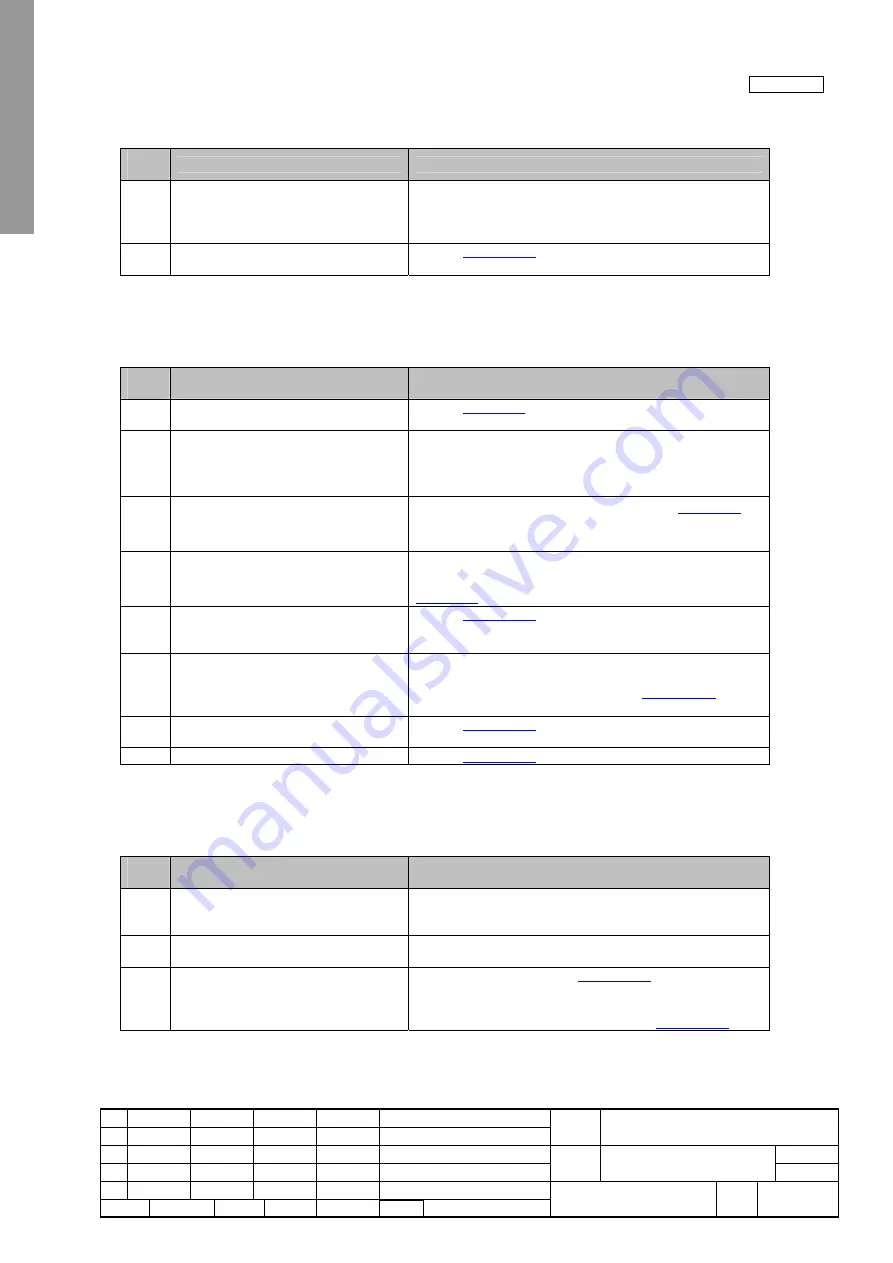

3-3-9. When calibrating white of scanned image

Table 3-3-9

Item

No.

Check items

How/where to check

1

Check the items listed in the right

column.

- Are the scan settings (density or color number) correct for the

application software used?

- Is the sheet guide (Guide P ASSY, White part) in the ADF

dirty?

2

Conduct the white adjustment by

Maintenance mode.

Refer to

Section 5-1-5

.

3-3-10. Frequent “U1: paper jam error”

Table 3-3-10

Item

No.

Check items

How/where to check

1

Do the documents satisfy paper

specification?

Refer to

Section 1-2

for paper specification

2

Have the documents been jogged?

•

Align the edge of documents for stable paper feeding.

•

Remove documents with crease or dog-ear.

•

Scanning different width of documents may cause skew

and result in paper jam.

3

Is Paper thickness switch set to “Thin”

while document thickness is more than

52 g/m

2

.

Set the switch to “Normal” position. Refer to

Section 1-1

for

Paper thickness switch.

4

Is Paper thickness switch set to

“Normal” while document thickness is

less than 52 g/m

2

.

Set the switch to “Thin” position. However, this does not mean

that feeding of thin paper less than 52 g/m

2

is assured. Refer to

Section 1-1

for Paper thickness switch.

5

Clean feed rollers, eject rollers and

plastic rollers and see if the error is

resolved.

Refer to

Section 1-7-1

.

6

Replace Pick roller and Pad ASSY and

see if the error is resolved.

Check the consumable counter from the TWAIN driver screen

or from the built-in Maintenance mode (Section 5-1-6). When

the counter exceeds the values shown in

Section 1-8-1

, replace

Pick roller or Pad ASSY.

7

Check the performance of Sensor PICK

and Sensor TOP.

Refer to

Section 5-1-2

for checking.

8

Is Cover open sensor malfunctioning?

Refer to

Section 5-1-2

for checking.

3-3-11. Error detection of “No paper on the Chute unit”

Table 3-3-11

Item

No.

Check items

How/where to check

1

Does the same symptom occur after

turning OFF and ON the scanner?

Press power button of the scanner for more than 2 seconds to

turn it OFF, and after more than 2 seconds elapse, press the

power button to turn the scanner ON.

2

Is there a slip of paper left near Hopper

empty sensor?

Open the ADF and check inside visually.

3

Check the performance of Hopper empty

sensor.

Conduct Maintenance mode (

Section 5-1-2

) to see if the sensor

works properly.

If the error still occurs, confirm that the cable is correctly

connected then replace the sensor. (Refer to

Section 4-9-7

.)