NewFEIMAS

Refer to Revision Record on page 2.

T.Anzai

Nov. 20, 2008

K.Okada

Rev

04

03

PAGE

14

/

138

PFU LIMITED

P1PA03334-B30X/6

Refer to Revision Record on page 2.

T.Anzai

July 7, 2008

K.Okada

Refer to Revision Record on page 2.

K.Okada

K.Okada

DESCRIPTION

CHECK

DATE

T.Anzai

APPR.

K.Okada

K.Okada

Aug.19, 2005

DESIG

N

DESIG

.

CUST.

I.Fujioka

I.Fujioka

T.Anzai

CHECK

fi-5530C/fi-5530C2

IMAGE SCANNER

MAINTENANCE MANUAL

APPR.

TITLE

DRAW.

No.

Feb.23, 2007

05

Section 1-2-2

1-2-2 Document Quality

This section describes the type and thickness of documents that can be loaded on the scanner and precautions.

- Recommended Document Type

Woodfree paper

Wood containing paper

When scanning the paper with the document type other than the above, perform a test-scanning with a few sheets of the

same type before executing the actual task in order to check whether or not the document can be scanned.

- Document Thickness

Paper thickness is expressed by the unit of “paper weight”. The following shows the paper thickness that can be scanned

by this scanner.

52 g/m

2

to 127 g/m

2

Only a paper weight of 127 g/m

2

is allowed for A8-size documents.

- Precautions

The following documents may not be scanned successfully.

-

Documents of non-uniform thickness (e.g. envelopes)

-

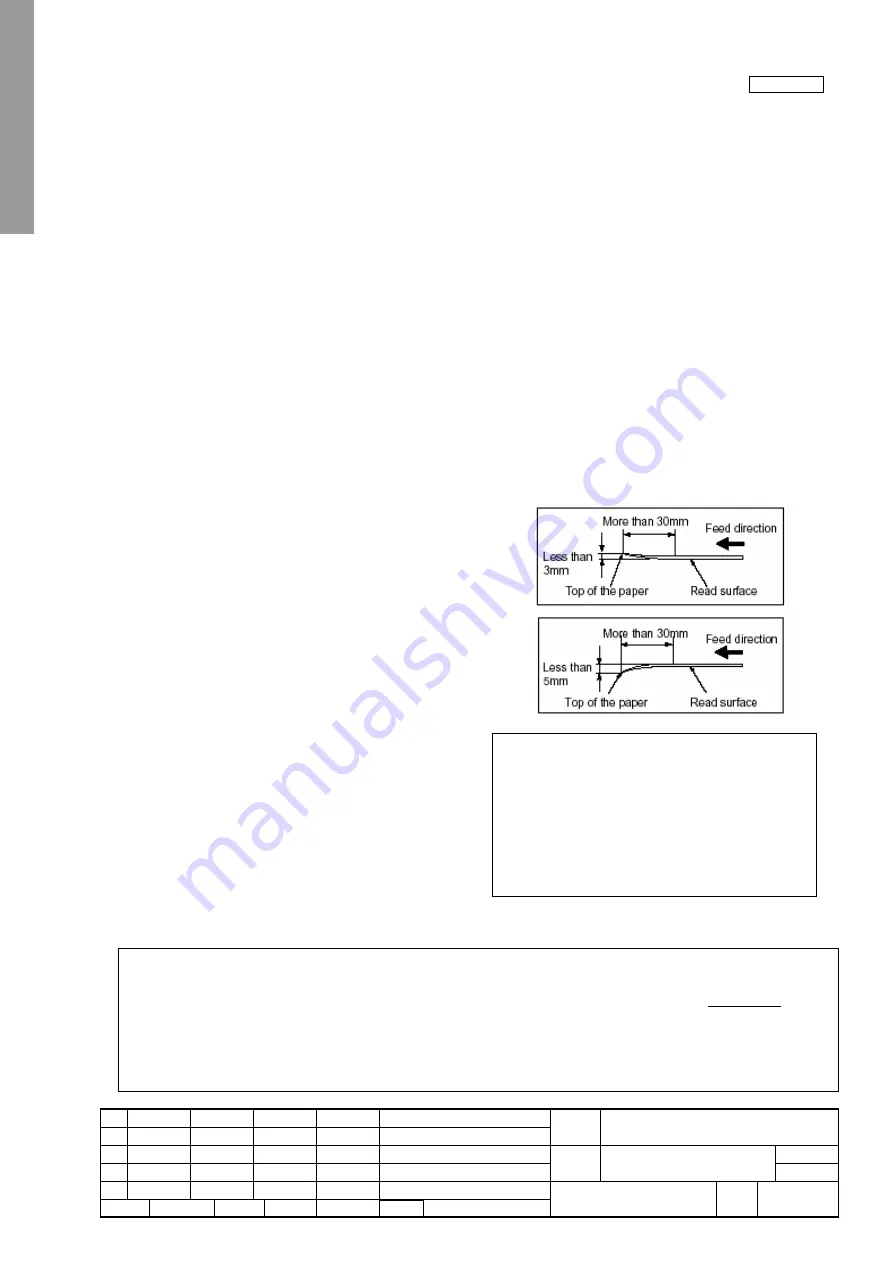

Wrinkled or curled documents (See right figure)

-

Folded or torn documents

-

Tracing paper

-

Coated paper

-

Carbon paper

-

Carbonless paper

-

Photosensitive paper

-

Perforated or punched documents

-

Documents that are not square or rectangular

-

Very thin documents

Do not use the following documents:

- Paper-clipped or stapled documents

-

Documents on which the ink is still wet

-

Documents smaller than A8 (Portrait) in size

-

Documents wider than A3 or 11 x 17 in size

-

Documents other than paper such as fabric, metal foil or transparencies

Note: - Carbonless paper contains chemical substances that may harm the Pad ASSY or rollers (e.g. Pick roller) when

documents are fed. Pay attention to the following:

Cleaning: If document jams occur frequently, clean the Pad ASSY and the Pick roller, by referring Section 1-7-1.

Replacement parts: The service life of the Pad ASSY and the Pick roller may be shortened compared to the case of

scanning wood containing paper documents.

- When scanning wood containing paper, the life of the Pad ASSY and the Pick roller may be shortened compared to the

case of scanning woodfree paper.

Note: - When scanning semi-transparent documents,

slide the [Brightness] bar to light to avoid

bleed through.

- To prevent the rollers from becoming dirty,

avoid scanning documents containing large

areas written or filled in pencil. If scanning of

such document is inevitable, clean the rollers

more frequently.