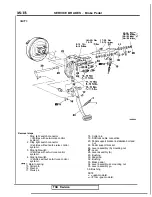

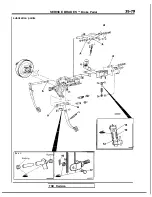

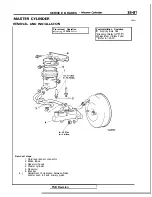

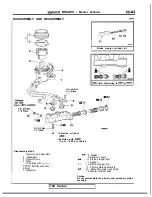

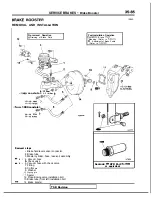

SERVICE BRAKES

Service Adjustment Procedures

When turned manually

POINTS IN WAVEFORM MEASUREMENT

3. Manually turning the wheel to be measured by

to 1

turn/second, measure the output voltage with a circuit

tester or oscilloscope.

Output voltage:

When measured with circuit tester: 70

or more

When measured with oscilloscope (max. voltage): 100

or more

Probable causes of low output voltage

Speed sensor pole piece-to-rotor clearance too large

l

Faulty speed sensor

4. Then, in order to observe the output state of the wheel

speed sensors, shift into low gear

vehicle) and drive

the wheels, observe the output voltage waveform of each

wheel speed sensor with an oscilloscope.

In the case of the FWD vehicle, observe the waveform with

an oscilloscope; for the front wheels, shift into low gear and

drive the wheels; for the rear wheels, turn the wheels

manually at a constant speed.

NOTE

1.

Waveform may also be observed by actually driving the

vehicle.

2.

The output voltage is low when the wheel speed is low

and increases as the wheel speed increases.

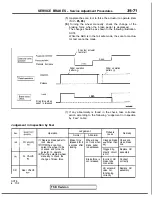

Symptom

Too small or zero waveform

amplitude

Probable causes

Faulty wheel speed sensor

Remedy

Replace sensor

Incorrect pole piece-to-rotor clearance

Adjust clearance

Waveform amplitude fluctuates

Axle hub eccentric or with large

Replace hub

excessively (this is no problem if

the minimum amplitude is 100

or more)

Noisy or disturbed waveform

Open circuit in sensor

Replace sensor

Open circuit in harness

Correct harness

Incorrectly mounted wheel speed sensor

Mount correctly

Rotor with missing or damaged teeth

Replace rotor

NOTE

The wheel speed sensor cable moves following motion of the front or rear suspension. Therefore, it is likely that it has an

open circuit only when driving on rough roads and it functions normally on

roads. It is, therefore, recommended

to observe sensor output voltage waveform also under special conditions, such as rough road

TSB Revision

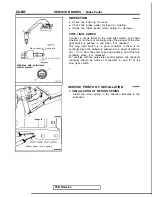

INSPECTION OF HYDRAULIC UNIT

INSPECTION BY FEEL

(1) Jack up the vehicle and support the vehicle with rigid racks

placed at the specified jack-up points.

Release the parking brake and determine the drag force

(drag torque) of each wheel by feel.

(3) Set the scan tool through the adapter harness

377)

as illustrated.

(4) After confirming that the shift lever or selector lever is in

the neutral position, start the engine.

The ABS warning light lights up, it goes into the scan tool

mode. In the scan tool mode, ABS does not function.

I

Summary of Contents for 1989 Galant

Page 2: ......

Page 4: ...00 z NOTES ...

Page 274: ...13 132 NOTE ...

Page 586: ...NOTES ...

Page 650: ...NOTE ...

Page 664: ...NOTES ...

Page 688: ...NOTES ...

Page 690: ......

Page 692: ......

Page 694: ......

Page 696: ......

Page 698: ......

Page 700: ...c ...

Page 702: ......

Page 704: ......

Page 706: ......

Page 708: ......

Page 710: ......

Page 712: ......

Page 714: ......

Page 716: ......

Page 718: ......

Page 720: ......

Page 722: ......

Page 724: ......

Page 729: ...23 23 NOTES ...

Page 860: ...NOTES ...

Page 921: ...NOTES ...

Page 948: ...33B 9 NOTES ...

Page 1121: ...NOTES ...

Page 1200: ...SERVICE BRAKES Brake Pedal 35 79 Lubrication points Part A 14AO256 1 14UOO5l TSB Revision ...

Page 1273: ...NOTES t ...