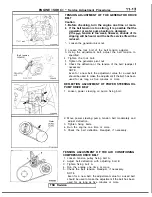

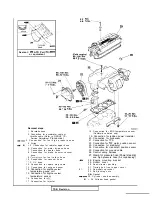

ENGINE <SOHC> Service Adjustment Procedures

DRIVE BELTS

TENSION ADJUSTMENT

Check that the belts are not damaged.

Power

pump

pulley

W ater

pulley

I

pulley

Generator

compressor

Crankshaft

pulley

pulley

Spindle-

RESET button

(2) Apply

(22

force to the belt back midway

between the pulleys as shown in the figure, measure the

deflection or, by using a belt-tension gauge, check the

belt’s tension.

Standard value:

Gauge

400 (88)

For

Deflection

Approx. 8.0

compressor

mm (in.)

For

Gauge

( 7 1 - 8 8 )

Deflection

mm (in.)

NOTE

There is more than one type of belt-tension gauge (type A and

type for example), so be sure to use the gauge according to

its instructions for use.

TSB Revision

Summary of Contents for 1989 Galant

Page 2: ......

Page 4: ...00 z NOTES ...

Page 274: ...13 132 NOTE ...

Page 586: ...NOTES ...

Page 650: ...NOTE ...

Page 664: ...NOTES ...

Page 688: ...NOTES ...

Page 690: ......

Page 692: ......

Page 694: ......

Page 696: ......

Page 698: ......

Page 700: ...c ...

Page 702: ......

Page 704: ......

Page 706: ......

Page 708: ......

Page 710: ......

Page 712: ......

Page 714: ......

Page 716: ......

Page 718: ......

Page 720: ......

Page 722: ......

Page 724: ......

Page 729: ...23 23 NOTES ...

Page 860: ...NOTES ...

Page 921: ...NOTES ...

Page 948: ...33B 9 NOTES ...

Page 1121: ...NOTES ...

Page 1200: ...SERVICE BRAKES Brake Pedal 35 79 Lubrication points Part A 14AO256 1 14UOO5l TSB Revision ...

Page 1273: ...NOTES t ...