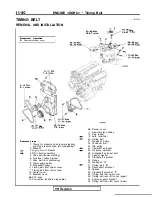

ENGINE <DOHC>

Timing Belt

TSB Revision

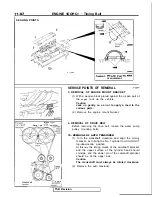

. ADJUSTMENT OF TIMING BELT TENSION

(1) After turning the crankshaft

turn counterclockwise,

turn it clockwise to move the No. 1 cylinder to top dead

center.

(2) Loosen the center bolt, and then, as shown in the

illustration, attach the special tool and a torque wrench

and apply a torque of 2.6-2.8 Nm

If

the body interferes with the special tool and the torque

wrench, use a jack to slightly raise the engine assembly.

NOTE

Use a torque wrench that is capable of measurement

of 0- 3 Nm (0- 2.2

(3) Holding the tensioner pulley with the special tool

and

torque wrench, tighten the center bolt to specification.

(4) Screw the tool into the engine left support bracket until

its end makes contact with the tensioner arm. At that

point, screw the tool in some more and then remove the

set wire attached to the auto tensioner.

(5) Remove the tool.

(6) Rotate the crankshaft two complete turns clockwise

and leave it as is for about 15 minutes. Then, measure

the auto tensioner protrusion “A” (distance between

the tensioner arm and auto tensioner body) to ensure

that it is up to specification.

Standard value: 3.8-4.5 mm

in.)

If it is out of specification, repeat steps (6) through (11)

until the specified value is obtained.

(7) If the clearance between the tensioner arm and the

auto tensioner body cannot be measured (when the

engine is being mounted, etc.), the following proce-

dures can be used to substitute for the ordinary method

of measurement.

the tensioner arm.

From that point of contact, further screw in the tool.

tensioner body is caused to move backward and the

tensioner arm contacts the auto tensioner body.

Check to be sure that the amount that the tool has

been screwed in (when the push rod moves back-

ward) is the standard value.

Standard value:

3 turns

Summary of Contents for 1989 Galant

Page 2: ......

Page 4: ...00 z NOTES ...

Page 274: ...13 132 NOTE ...

Page 586: ...NOTES ...

Page 650: ...NOTE ...

Page 664: ...NOTES ...

Page 688: ...NOTES ...

Page 690: ......

Page 692: ......

Page 694: ......

Page 696: ......

Page 698: ......

Page 700: ...c ...

Page 702: ......

Page 704: ......

Page 706: ......

Page 708: ......

Page 710: ......

Page 712: ......

Page 714: ......

Page 716: ......

Page 718: ......

Page 720: ......

Page 722: ......

Page 724: ......

Page 729: ...23 23 NOTES ...

Page 860: ...NOTES ...

Page 921: ...NOTES ...

Page 948: ...33B 9 NOTES ...

Page 1121: ...NOTES ...

Page 1200: ...SERVICE BRAKES Brake Pedal 35 79 Lubrication points Part A 14AO256 1 14UOO5l TSB Revision ...

Page 1273: ...NOTES t ...