13-8

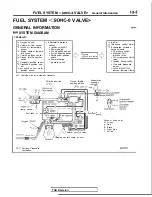

FUEL SYSTEM

VALVE> Troubleshooting

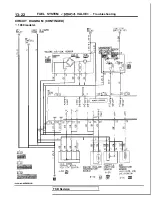

TROUBLESHOOTING

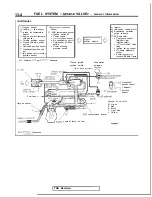

EXPLANATION OF TROUBLESHOOTING PROCEDURES

Effective troubleshooting procedures related to problems of the

system are described below.

START

1.

of the

2. Read-out of the diag-

nostic trouble code.

I

3. Assumption of the prob-

able cause of the mal-

function, and

of the

appropriate check

4. Checking of the engine

control module’s input

and output signals.

6. Checking of the

component itself.

8. Confirmation that repair

procedures have been

completed and

that

reoccurrence has been

prevented.

Confirmation of the malfunction.

l

Cause the malfunction to reoccur and check the details

of the malfunction and the conditions (engine condition,

driving conditions, etc.) when the malfunction reoccurs.

2.

Read-out of the diagnostic trouble code.

l

When the diagnostic trouble code is read out and the

diagnostic trouble code is output, refer to the diagnos-

tic chart and repair the indicated location of the mal-

function.

3.

Assumption of the probable cause of the malfunction, and

determination of the appropriate check points.

l

Refer to the “CHECK CHART CLASSIFIED BY PROB-

LEM SYMPTOMS” and confirm the sequence of check-

ing for the indicated malfunction.

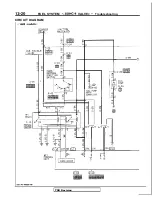

4. Checking of the engine control module’s input and output

signals.

Using the scan tool or an oscilloscope, check the input

and output signals of the engine control module.

If the input and output signals are normal, sensor input/

actuator control can. be judged to be normal, so check

the

input

and output signals of the subsequent check

point.

5.

Checking of the

component’s harness.

l

If an abnormal condition of the input and output signals

of the engine control module is discovered, check, and

repair if necessary, the body harness of the

com-

ponent.

l

After making this repair, again check the input and out-

put signals of the engine control module; if they are

normal, proceed to the checking of the input and out-

put signals of the subsequent check point.

6.

Checking of the

component itself.

If the input and output signals of the engine control

module are abnormal even though the body harness is

normal, check the

component itself, and repair or

replace as necessary.

l

After making this repair or replacement, again check

the input and output signals of the engine control mod-

ule; if they are normal, proceed to the checking of the

input and output signals of the subsequent check point.

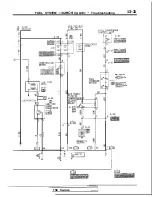

7.

Rechecking of the cause of the malfunction, and repair.

l

If the input and output signals of the engine control

module are abnormal even though the harness check-

ing and the checking of the unit itself indicate that the

condition is normal, refer to the troubleshooting hints to

recheck the probable cause, and then check other

groups and reapir as necessary.

8. Confirmation that repair procedures have been completed

and that reoccurrence has been prevented.

l

Perform a test to try to get the malfunction to reoccur,

and confirm that it does not.

Eliminate the true cause of the malfunction so as to

prevent its reoccurrence.

TSB Revision

Summary of Contents for 1989 Galant

Page 2: ......

Page 4: ...00 z NOTES ...

Page 274: ...13 132 NOTE ...

Page 586: ...NOTES ...

Page 650: ...NOTE ...

Page 664: ...NOTES ...

Page 688: ...NOTES ...

Page 690: ......

Page 692: ......

Page 694: ......

Page 696: ......

Page 698: ......

Page 700: ...c ...

Page 702: ......

Page 704: ......

Page 706: ......

Page 708: ......

Page 710: ......

Page 712: ......

Page 714: ......

Page 716: ......

Page 718: ......

Page 720: ......

Page 722: ......

Page 724: ......

Page 729: ...23 23 NOTES ...

Page 860: ...NOTES ...

Page 921: ...NOTES ...

Page 948: ...33B 9 NOTES ...

Page 1121: ...NOTES ...

Page 1200: ...SERVICE BRAKES Brake Pedal 35 79 Lubrication points Part A 14AO256 1 14UOO5l TSB Revision ...

Page 1273: ...NOTES t ...