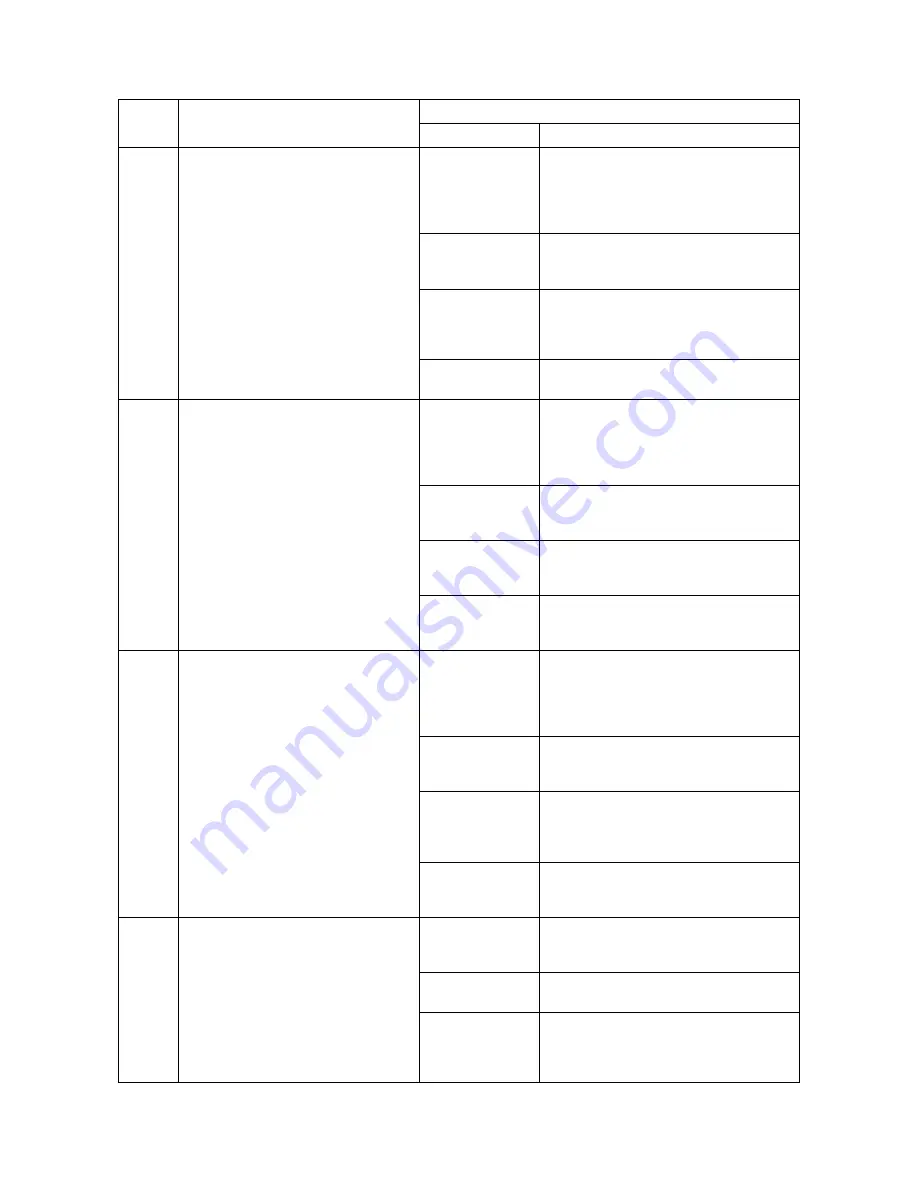

2KN/2KP

1-4-35

C2250

Cleaning motor error

• LOCK signal remains high for 1 s,

200 ms after the cleaning motor has

turned on.

Poor contact in the

drive motor con-

nector terminals.

Check the connection of connector YC5 on

the engine PWB. Reinsert the connector.

Also check for continuity within the connec-

tor cable. If none, remedy or replace the

cable.

Defective cleaning

motor rotation con-

trol circuit.

Replace the cleaning motor.

Defective drive

transmission sys-

tem.

Check if the rollers and gears rotate

smoothly. If not, grease the bushings and

gears. Check for broken gears and replace if

any.

Defective engine

PWB.

Replace the engine PWB.

C2300

Fuser motor error

• LOCK signal remains high for 1 s, 1 s

after the fuser motor has turned on.

Poor contact in the

fuser motor con-

nector terminals.

Check the connection of connector YC2 and

YC4 on the duplex PWB. Reinsert the con-

nector. Also check for continuity within the

connector cable. If none, remedy or replace

the cable.

Defective fuser

motor rotation con-

trol circuit.

Replace the fuser motor.

Defective drive

transmission sys-

tem.

Check if the rollers and gears rotate smoothly.

If not, grease the bushings and gears. Check

for broken gears and replace if any.

Defective duplex

PWB or engine

PWB.

Replace the duplex PWB or the engine

PWB.

C2550

Transfer motor error

• LOCK signal remains high for 1 s, 1 s

after the transfer motor has turned on.

Poor contact in the

transfer motor con-

nector terminals.

Check the connection of connector YC2 and

YC3 on the cassette PWB and YC4 on the

engine PWB. Reinsert the connector. Also

check for continuity within the connector

cable. If none, remedy or replace the cable.

Defective transfer

motor rotation con-

trol circuit.

Replace the transfer motor.

Defective drive

transmission sys-

tem.

Check if the rollers and gears rotate

smoothly. If not, grease the bushings and

gears. Check for broken gears and replace if

any.

Defective cassette

PWB or engine

PWB.

Replace the cassette PWB or the engine

PWB.

C2640

Side feeder drive motor error

Overloaded side

feeder drive motor

Verify that the side feeder motor or the paper

feeding mechanism is not interrupted by any

objects.

Defective side

feeder drive motor.

Replace the side feeder drive motor.

Defective side

feeder main PWB.

Replace the side feeder main PWB.

Code

Contents

Remarks

Causes

Check procedures/corrective measures

Summary of Contents for TASKalfa 620

Page 1: ...SERVICE MANUAL Published in August 2009 842KP112 2KPSM062 Rev 2 TASKalfa 620 820 ...

Page 4: ...This page is intentionally left blank ...

Page 10: ...This page is intentionally left blank ...

Page 144: ...2KN 2KP 1 3 106 This page is intentionally left blank ...

Page 308: ...2KN 2KP 1 5 88 This page is intentionally left blank ...

Page 412: ...2KN 2KP 2 3 60 This page is intentionally left blank ...

Page 435: ...1 1 INSTALLATION GUIDE INSTALLATION GUIDE FOR SIDE FEEDER ...

Page 442: ...INSTALLATION GUIDE FOR LARGE SIZE SIDE FEEDER ...

Page 460: ...INSTALLATION GUIDE FOR DOCUMENT FINISHER ...

Page 475: ...INSTALLATION GUIDE FOR CENTERFOLD UNIT ...

Page 490: ...INSTALLATION GUIDE FOR MULTI JOB TRAY ...

Page 501: ...INSTALLATION GUIDE FOR PUNCH UNIT ...

Page 512: ...INSTALLATION GUIDE FOR STOPPER GUIDE ...

Page 515: ...INSTALLATION GUIDE FOR PRINTING SYSTEM ...

Page 518: ...INSTALLATION GUIDE FOR SCAN SYSTEM ...

Page 520: ......

Page 521: ......