2KN/2KP

1-4-16

(16)

A paper jam in the

paper feed section is

indicated during

copying (multiple

sheets in deck paper

feed section 1).

Jam code 28

Broken deck conveying

switch 2 actuator.

Check visually and replace deck conveying switch 2 if its actuator

is broken.

Defective deck conveying

switch 2.

Run maintenance item U031 and turn deck conveying switch 2 on

and off manually. Replace deck conveying switch 2 if indication of

the corresponding sensor on the touch panel is not displayed in

reverse.

Defective timing switch 2.

Run maintenance item U031 and turn timing switch 2 on and off

manually. Replace timing switch 2 if indication of the correspond-

ing sensor on the touch panel is not displayed in reverse.

The deck conveying roller is

dirty with paper powder.

Check and, if it is dirty, clean it.

The deck conveying roller is

deformed or worn.

Check and, if it is deformed or worn, fix or replace it.

(17)

A paper jam in the

paper feed section is

indicated during

copying (multiple

sheets in deck paper

feed section 2).

Jam code 29

Broken deck conveying

switch 1 actuator.

Check visually and replace deck conveying switch 1 if its actuator

is broken.

Defective deck conveying

switch 1.

Run maintenance item U031 and turn deck conveying switch 1 on

and off manually. Replace deck conveying switch 1 if indication of

the corresponding sensor on the touch panel is not displayed in

reverse.

Broken deck conveying

switch 2 actuator.

Check visually and replace deck conveying switch 2 if its actuator

is broken.

Defective deck conveying

switch 2.

Run maintenance item U031 and turn deck conveying switch 2 on

and off manually. Replace deck conveying switch 2 if indication of

the corresponding sensor on the touch panel is not displayed in

reverse.

The deck conveying roller is

dirty with paper powder.

Check and, if it is dirty, clean it.

The deck conveying roller is

deformed or worn.

Check and, if it is deformed or worn, fix or replace it.

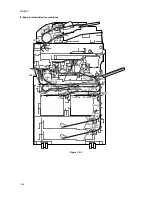

(18)

A paper jam in the

paper feed section is

indicated during

copying (multiple

sheets in optional

side feeder).

Jam code 30

Side feeder

Broken side feeder feed

switch actuator.

Check visually and replace the side feeder feed switch if its actua-

tor is broken.

Defective side feeder feed

switch.

Run maintenance item U031 and turn the side feeder feed switch

on and off manually. Replace the side feeder feed switch if indica-

tion of the corresponding sensor on the touch panel is not dis-

played in reverse.

The feed roller or feed left

roller is dirty with paper

powder.

Check and, if it is dirty, clean it.

The feed roller or feed left

roller is deformed or worn.

Check and, if it is deformed or worn, fix or replace it.

Problem

Causes/check procedures

Corrective measures

Summary of Contents for TASKalfa 620

Page 1: ...SERVICE MANUAL Published in August 2009 842KP112 2KPSM062 Rev 2 TASKalfa 620 820 ...

Page 4: ...This page is intentionally left blank ...

Page 10: ...This page is intentionally left blank ...

Page 144: ...2KN 2KP 1 3 106 This page is intentionally left blank ...

Page 308: ...2KN 2KP 1 5 88 This page is intentionally left blank ...

Page 412: ...2KN 2KP 2 3 60 This page is intentionally left blank ...

Page 435: ...1 1 INSTALLATION GUIDE INSTALLATION GUIDE FOR SIDE FEEDER ...

Page 442: ...INSTALLATION GUIDE FOR LARGE SIZE SIDE FEEDER ...

Page 460: ...INSTALLATION GUIDE FOR DOCUMENT FINISHER ...

Page 475: ...INSTALLATION GUIDE FOR CENTERFOLD UNIT ...

Page 490: ...INSTALLATION GUIDE FOR MULTI JOB TRAY ...

Page 501: ...INSTALLATION GUIDE FOR PUNCH UNIT ...

Page 512: ...INSTALLATION GUIDE FOR STOPPER GUIDE ...

Page 515: ...INSTALLATION GUIDE FOR PRINTING SYSTEM ...

Page 518: ...INSTALLATION GUIDE FOR SCAN SYSTEM ...

Page 520: ......

Page 521: ......