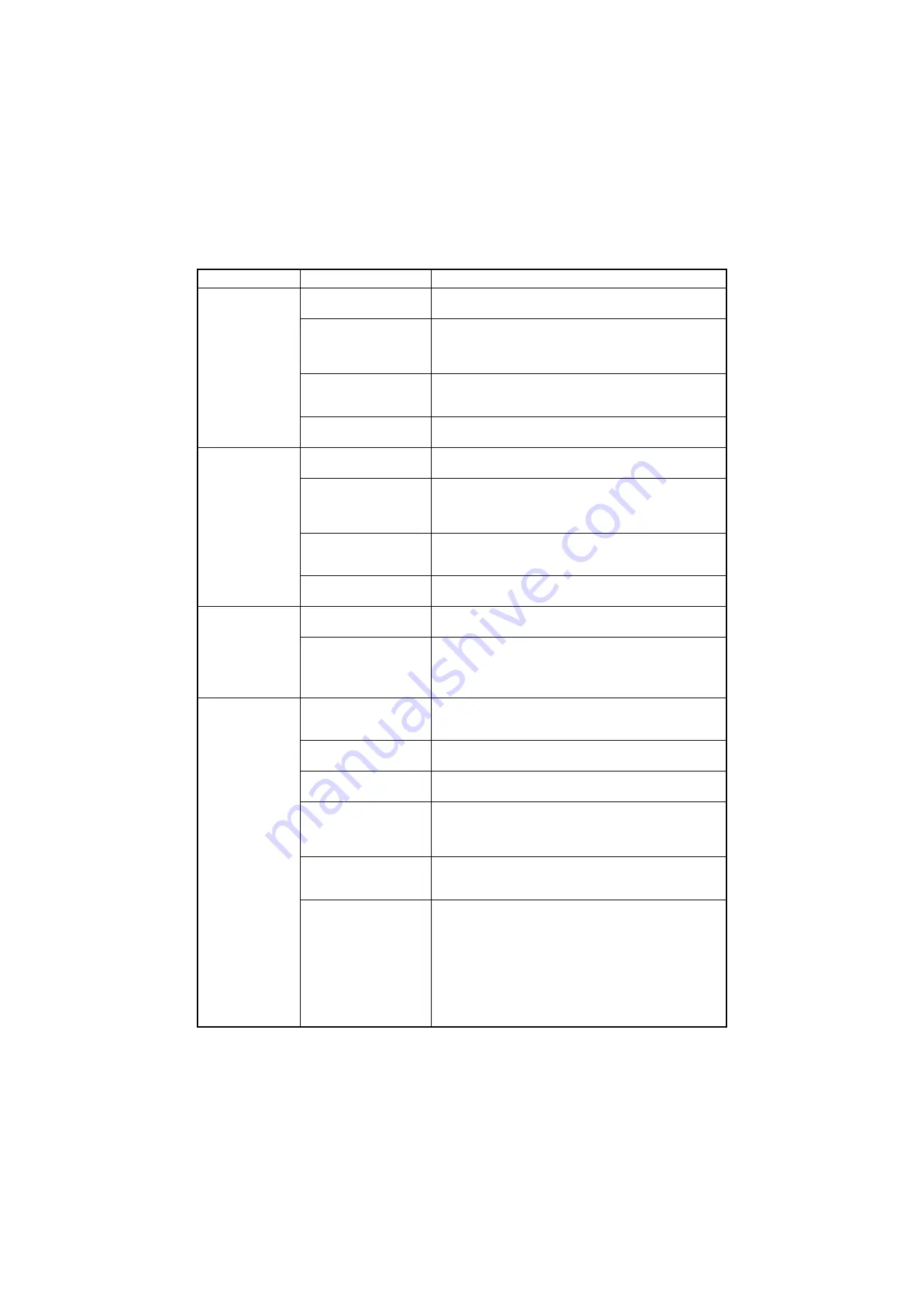

2KR/2KS

1-4-17

(17)

A paper jam in the

fuser section is indi-

cated during copying

(jam in fuser section).

Jam codes 40 to 44,

46 and 47

Broken eject switch or feed-

shift switch actuator.

Check visually and replace switch.

Defective switch.

Run maintenance item U031 and turn switch on and off manually.

Replace the switch if indication of the corresponding switch on the

touch panel is not displayed in reverse.

Eject switch, feedshift switch

Check if the registration

clutch malfunctions.

Run maintenance item U032 and select the registration clutch on

the touch panel to be turned on and off. Check the status and rem-

edy if necessary.

Electrical problem with the

registration clutch.

Check (see page 1-4-57).

(18)

A paper jam in the

eject section is indi-

cated during copying

(jam in eject section).

Jam code 50

Broken eject switch actua-

tor.

Check visually and replace switch.

Defective switch.

Run maintenance item U031 and turn switch on and off manually.

Replace the switch if indication of the corresponding switch on the

touch panel is not displayed in reverse.

Registration switch, eject switch

Check if the registration

clutch malfunctions.

Run maintenance item U032 and select the registration clutch on

the touch panel to be turned on and off. Check the status and rem-

edy if necessary.

Electrical problem with the

registration clutch.

Check (see page 1-4-57).

(19)

A paper jam in the

eject section is indi-

cated during copying

(jam in job separator

eject section).

Jam code 51

Broken feedshift switch or

job eject switch actuator.

Check visually and replace switch.

Defective switch.

Run maintenance item U031 and turn switch on and off manually.

Replace the switch if indication of the corresponding switch on the

touch panel is not displayed in reverse.

Feedshift switch, job eject switch

(20)

A paper jam in the

feedshift section is

indicated during

copying (jam in feed-

shift section).

Jam code 52

Check if the feedshift sole-

noid malfunctions.

Run maintenance item U033 and select the feedshift solenoid on

the touch panel to be turned on and off. Check the status and rem-

edy if necessary.

Electrical problem with the

feedshift solenoid.

Check (see page 1-4-57).

Broken feedshift switch

actuator.

Check visually and replace switch.

Defective switch.

Run maintenance item U031 and turn switch on and off manually.

Replace the switch if indication of the corresponding switch on the

touch panel is not displayed in reverse.

Feedshift switch, registration switch

Check if the registration

clutch malfunctions.

Run maintenance item U032 and select the registration clutch on

the touch panel to be turned on and off. Check the status and rem-

edy if necessary.

Electrical problem with the

registration clutch.

Check (see page 1-4-57).

Problem

Causes/check procedures

Corrective measures

Summary of Contents for TASKalfa 420i

Page 1: ...SERVICE MANUAL Published in May 2010 842KS113 2KSSM063 Rev 3 TASKalfa 420i TASKalfa 520i ...

Page 4: ...This page is intentionally left blank ...

Page 10: ...This page is intentionally left blank ...

Page 14: ...2KR 2KS This page is intentionally left blank ...

Page 224: ...2KR 2KS 1 4 66 This page is intentionally left blank ...

Page 328: ...2KR 2KS 2 3 30 This page is intentionally left blank ...

Page 371: ...INSTALLATION GUIDE FOR PAPER FEEDER ...

Page 381: ...INSTALLATION GUIDE FOR 3000 SHEETS PAPER FEEDER ...

Page 436: ...INSTALLATION GUIDE FOR CENTER FOLDING UNIT ...

Page 450: ...INSTALLATION GUIDE FOR MAILBOX ...

Page 458: ...INSTALLATION GUIDE FOR HOLE PUNCH UNIT ...

Page 470: ...INSTALLATION GUIDE FOR BUILT IN FINISHER ...

Page 483: ...INSTALLATION GUIDE FOR JOB SEPARATOR ...

Page 491: ...INSTALLATION GUIDE FOR FAX System ...

Page 507: ......

Page 508: ......