Sample of Grease Locations for Edge-SS

5-20

KVAL Operation/Service Manual

Sample of Grease Locations for Edge-SS

This machine is a powerful electro-mechanical

motion control system. If servicing this machine, fol-

low the safety guidelines. Failure to do so can result in

damage to equipment and/or serious injury to person-

nel.

Shutdown the machine and follow the

“Lock Out

Tag Out procedures

Caution

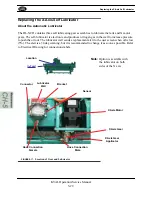

Servo Motor Drive Assembly Locations (Edge-SS)

Identify zerk fittings and apply EP-2 grease. Find the X, Y and Z axis rails to identify bearings.

Some bearings may be difficult to get access to. Use an extender to reach tight areas. Make sure

that

Lockout/Tagout

has been performed before maintenance. For recommended greasing sched-

ule,

see “Ball Screw Drive Assembly” on page

5-18.

X-Axis Servo Motor

Y-Axis Servo Motor

Z-Axis Servo Motor

Deep Drill Z-Axis Servo Motor

Feeler Servo Motor

EP-2 Grease

FIGURE 5-10.

Summary of Contents for Edge-SS

Page 5: ...KVAL Edge SS Operation Service Manual ...

Page 12: ...KVAL Edge SS Line Operation Service Manual ...

Page 32: ...Safety Sign Off Sheet 1 20 KVAL Operation Service Manual ...

Page 35: ...Definitions 2 45 KVAL Operation Service Manual ...

Page 91: ...Definitions KVAL Operation Service Manual 2 56 ...

Page 109: ...System IT Administration 4 4 KVAL Operation Service Manual ...

Page 142: ...Collet Torque Values 5 33 KVAL Operation Service Manual ...

Page 143: ...Troubleshooting Electrical Problems 6 30 KVAL Operation Service Manual ...

Page 173: ......

Page 177: ......

Page 178: ......

Page 179: ......