Replacing the X-Axis Self Lubricator

5-31

KVAL Operation/Service Manual

7.

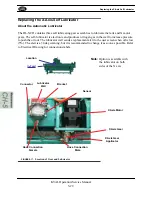

Disconnect the sensor wires from the corresponding node. (Blue to - VDC, Brown

to + VDC, Black to input)

8.

Loosen the bracket, and remove the well from the side of the machine. Do not dis-

card yet.

9.

Remove the old hose from the bottom of lubricator well and the applicator.

10.

Attach the new hose to the new well and the applicator.

11.

Bracket the new well against the machine.

12.

Slide the black and red wires into the connector. Secure with a small screw driver.

13.

Polarity is not an issue, but for consistency replace wires as they were.

14.

Route sensor wires to the corresponding node and connect to the correct terminals.

15.

After lubricator well is secured on machine, perform a test run.

16.

Verify the oil is being applied to the gear and there is no alert on the user screen.

The lubricator well will have blinking light when in operation.

17.

Reattach grate and secure wires with a zip tie.

Summary of Contents for Edge-SS

Page 5: ...KVAL Edge SS Operation Service Manual ...

Page 12: ...KVAL Edge SS Line Operation Service Manual ...

Page 32: ...Safety Sign Off Sheet 1 20 KVAL Operation Service Manual ...

Page 35: ...Definitions 2 45 KVAL Operation Service Manual ...

Page 91: ...Definitions KVAL Operation Service Manual 2 56 ...

Page 109: ...System IT Administration 4 4 KVAL Operation Service Manual ...

Page 142: ...Collet Torque Values 5 33 KVAL Operation Service Manual ...

Page 143: ...Troubleshooting Electrical Problems 6 30 KVAL Operation Service Manual ...

Page 173: ......

Page 177: ......

Page 178: ......

Page 179: ......