Sample of Grease Locations for Edge-SS

5-21

KVAL Operation/Service Manual

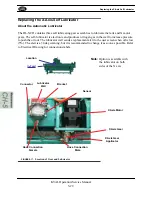

Locations of Bearings on the Cutting Head of the Edge-SS

Approximatively 1 Gram (one pump from grease gun) of Dura-Lith Grease

(KVAL P/N: Lube EP-2).

Every 250 hours of operation

.

Identify zerk fittings and apply EP-2 grease. Find the X, Y and Z axis rails to identify bearings.

Some bearings may be difficult to get access to. Use an extender to reach tight areas. Make sure

that

Lockout/Tagout

has been performed before maintenance.

EP-2 Grease

FIGURE 5-11.

Cutting Head Bearing Locations

Deep Drill Bearing Locations (Option)

Identify zerk fittings and apply EP-2 grease. Find the X, Y and Z axis rails to identify bearings.

Some bearings may be difficult to get access to. Use an extender to reach tight areas. Make sure

that

Lockout/Tagout

has been performed before maintenance.

EP-2 Grease

FIGURE 5-12.

Deep Drill Bearing Locations

Summary of Contents for Edge-SS

Page 5: ...KVAL Edge SS Operation Service Manual ...

Page 12: ...KVAL Edge SS Line Operation Service Manual ...

Page 32: ...Safety Sign Off Sheet 1 20 KVAL Operation Service Manual ...

Page 35: ...Definitions 2 45 KVAL Operation Service Manual ...

Page 91: ...Definitions KVAL Operation Service Manual 2 56 ...

Page 109: ...System IT Administration 4 4 KVAL Operation Service Manual ...

Page 142: ...Collet Torque Values 5 33 KVAL Operation Service Manual ...

Page 143: ...Troubleshooting Electrical Problems 6 30 KVAL Operation Service Manual ...

Page 173: ......

Page 177: ......

Page 178: ......

Page 179: ......