Lubrication Schedule

5-14

KVAL Operation/Service Manual

Lubrication Schedule

KVAL recommends the following lubrication schedule to ensure that the machine operates prop-

erly.

TABLE 5-1.

Recommended Lubrication Schedule

Type of

Assembly

Recommended Schedule

Recommended

Lubrication Type

Linear Bearing

Every 250 Hours of Machine Operation

Dura-Lith Grease (KVAL P/N Lube

EP-2)

Pillow Block Bearing

Idler Shaft

Flange Block Bearing

Ball Screw

Every 80 Hours of Machine Operation

Tapered Bearing

Once a Year

Air Line Lubricator

One drop of oil every 2 or 3 cycles

Check the lines every week to two

weeks

Note: Some CNC Machines drop every

5-10 cycles.

Either lubricant listed below is

approved to use.

• KVAL P/N SYSLUBG

• Chevron AW Hydraulic Oil 32

• G-C lubricants light AW R&O

• Mobile DTE 24

• Shell Tellus32

• Gulf Harmony 32

Gear Box

Recommended not to Grease

• AGMA #8 gear lube

• MOBILUBE HD 80 W-90

• or equivalent

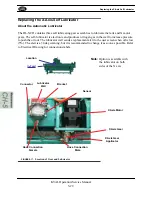

Typical Lucubration Kit

KVAL Part Number: LUBEKIT

Hydraulic Oil

Grease Gun

Extension

Adapter Needle

Nozzle

E Adapter Needle

Nozzle

EP-2 Multi-FAK

Grease

Silicone Spray

Summary of Contents for Edge-SS

Page 5: ...KVAL Edge SS Operation Service Manual ...

Page 12: ...KVAL Edge SS Line Operation Service Manual ...

Page 32: ...Safety Sign Off Sheet 1 20 KVAL Operation Service Manual ...

Page 35: ...Definitions 2 45 KVAL Operation Service Manual ...

Page 91: ...Definitions KVAL Operation Service Manual 2 56 ...

Page 109: ...System IT Administration 4 4 KVAL Operation Service Manual ...

Page 142: ...Collet Torque Values 5 33 KVAL Operation Service Manual ...

Page 143: ...Troubleshooting Electrical Problems 6 30 KVAL Operation Service Manual ...

Page 173: ......

Page 177: ......

Page 178: ......

Page 179: ......