Replacing the X-Axis Self Lubricator

5-30

KVAL Operation/Service Manual

Replace the Lubricator Well

The lubricator kit part number is

“Wit Lubricating Kit”.

It contains, lubricator well,

hose (with oil) and its connectors, bracket, and sensor. Follow the instructions on the

next page.

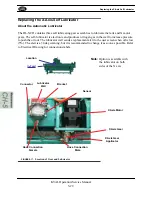

Well

Hose

Sensor

Hose Connectors

Clamp

FIGURE 5-18.

Wit Lubricating Kit

1.

Shutdown the machine and follow the Lockout Tagout procedure, in Chapter 1.

2.

Prepare to gain access to the X axis motor gear and gear applicator, by removing the

grate below the heads.

3.

If needed, cut the hose included in the kit to match the one on the machine.

4.

Attach the 2 hose connectors to the ends of the new hose.

5.

On the new lubricator well, set the dip switches.

• Remove the protective top from lubri-

cator well. Dip switch is located on

the top.

• Set the number 5 switch to the “ON”

position. This sets Lubricator to a

yearly flow cycle.

• Set the number 7 switch to the “ON”

position. This turns the Lubricator

“ON”

• Ensure the remaining switches are set

to “OFF”

ON

6.

Disconnect the black and red wires from the machine connector with a small screw-

driver.

Summary of Contents for Edge-SS

Page 5: ...KVAL Edge SS Operation Service Manual ...

Page 12: ...KVAL Edge SS Line Operation Service Manual ...

Page 32: ...Safety Sign Off Sheet 1 20 KVAL Operation Service Manual ...

Page 35: ...Definitions 2 45 KVAL Operation Service Manual ...

Page 91: ...Definitions KVAL Operation Service Manual 2 56 ...

Page 109: ...System IT Administration 4 4 KVAL Operation Service Manual ...

Page 142: ...Collet Torque Values 5 33 KVAL Operation Service Manual ...

Page 143: ...Troubleshooting Electrical Problems 6 30 KVAL Operation Service Manual ...

Page 173: ......

Page 177: ......

Page 178: ......

Page 179: ......