300 Cycle Maintenance Steps

5-4

KVAL Operation/Service Manual

300 Cycle Maintenance Steps

Follow Lockout Tagout procedures

.

Clean, Clean, Clean!

Sawdust and grime build-up can cause issues with the operation of the machine.

Use pressured air to blow off dust and debris on entire machine. Use a clean rag to clean areas

not affected by pressurized air.

Also blow out any dust collection units.

Check vertical bearings for loose screws.

Loose screws could cause bearing damage.

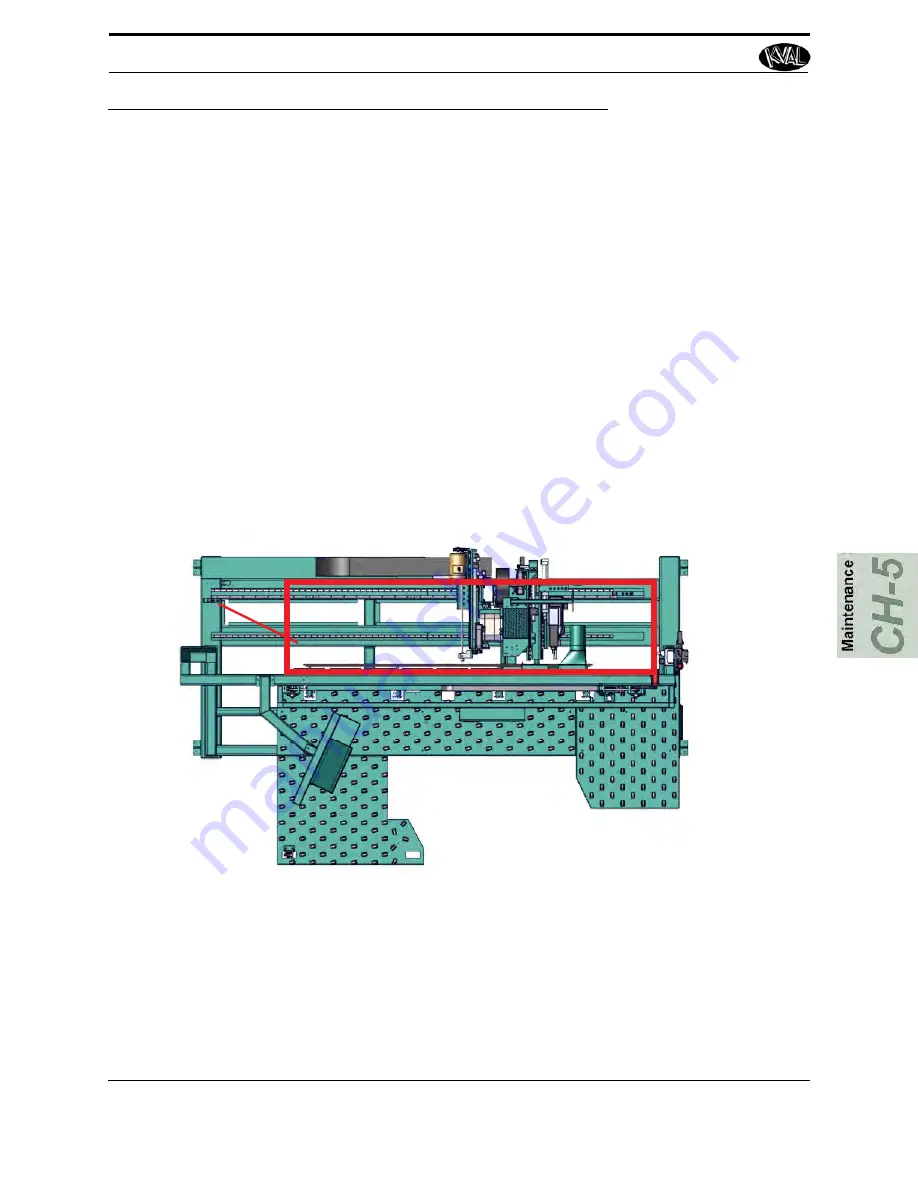

High Dust Accumulation Areas

Summary of Contents for Edge-SS

Page 5: ...KVAL Edge SS Operation Service Manual ...

Page 12: ...KVAL Edge SS Line Operation Service Manual ...

Page 32: ...Safety Sign Off Sheet 1 20 KVAL Operation Service Manual ...

Page 35: ...Definitions 2 45 KVAL Operation Service Manual ...

Page 91: ...Definitions KVAL Operation Service Manual 2 56 ...

Page 109: ...System IT Administration 4 4 KVAL Operation Service Manual ...

Page 142: ...Collet Torque Values 5 33 KVAL Operation Service Manual ...

Page 143: ...Troubleshooting Electrical Problems 6 30 KVAL Operation Service Manual ...

Page 173: ......

Page 177: ......

Page 178: ......

Page 179: ......