Description of Air Input System

5-22

KVAL Operation/Service Manual

Description of Air Input System

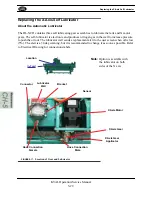

There are two types of air inputs on KVAL machinery. Not all machines have lubricator option

installed. Check your machine or Air prints to verify installation.

Air Input with Lubrication

The air input system takes in shop air and supplies clean dry air (CDA) and lubricated air to the

machine. The clean dry air is diverted to blow off nozzles. The lubricator, located after the CDA

filters, delivers the lubricated air to valve banks and air cylinders.

Shop Air

Input

Air On-

Off

Muffler

Filter (purge)

Pressure Gauge with adjust

Clean Dry Air (CDA) to

Air Blow Off

Lubricator

Lubricated

Air Output

FIGURE 5-13.

Typical Air Line Filter and Lubrication System

Adjusting the Air Line Lubricator

Using the knob on the top of the lubricator, adjust until one drop per every other cycle

is used (as observed through sight glass.)

(Sight Glass). When the oiler has run dry,

open the knob all the way until flow begins.

Once you have a steady flow, tighten knob

back down until you have one drop per

every other cycle.

Drop will form at end of cane shaped tube

visible inside glass.

Top of Lubricator

Summary of Contents for Edge-SS

Page 5: ...KVAL Edge SS Operation Service Manual ...

Page 12: ...KVAL Edge SS Line Operation Service Manual ...

Page 32: ...Safety Sign Off Sheet 1 20 KVAL Operation Service Manual ...

Page 35: ...Definitions 2 45 KVAL Operation Service Manual ...

Page 91: ...Definitions KVAL Operation Service Manual 2 56 ...

Page 109: ...System IT Administration 4 4 KVAL Operation Service Manual ...

Page 142: ...Collet Torque Values 5 33 KVAL Operation Service Manual ...

Page 143: ...Troubleshooting Electrical Problems 6 30 KVAL Operation Service Manual ...

Page 173: ......

Page 177: ......

Page 178: ......

Page 179: ......