455

Appendix

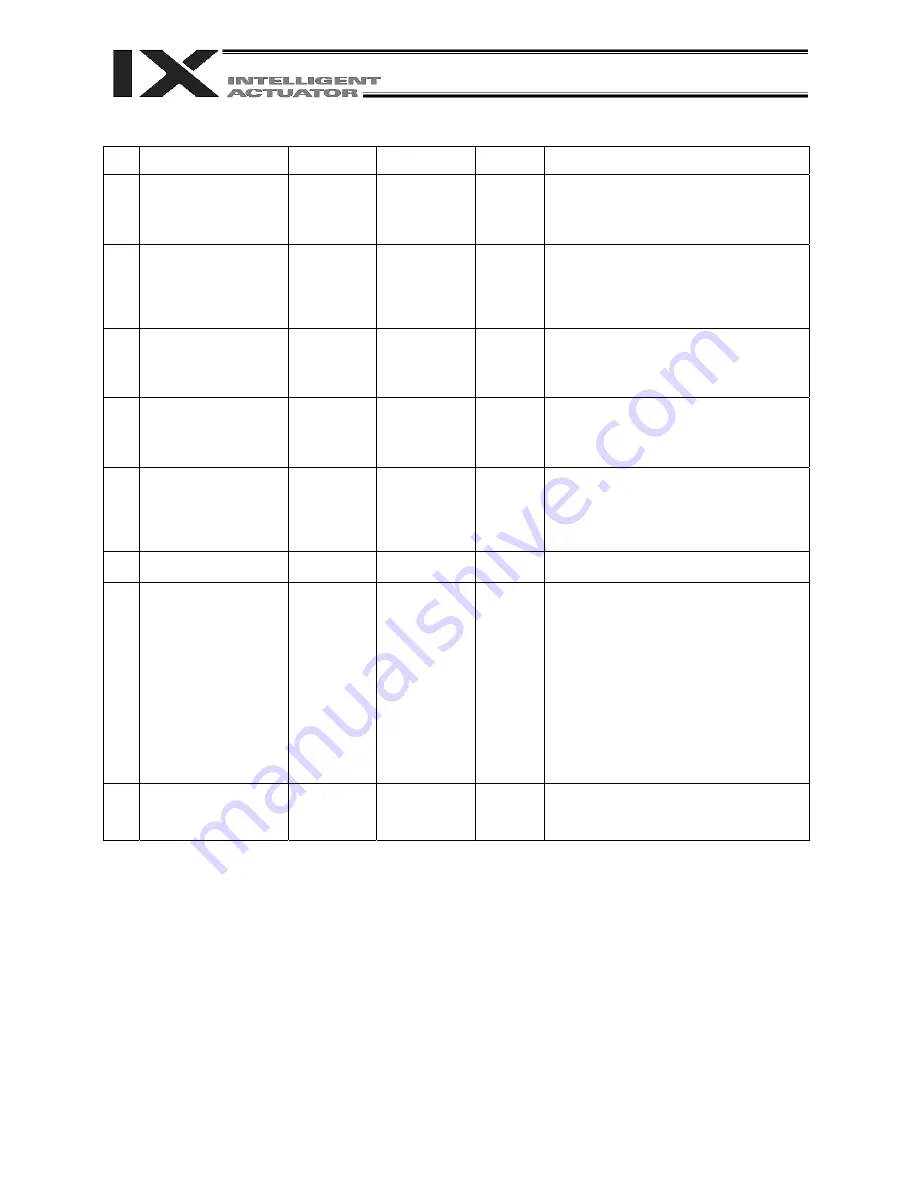

Axis-Specific Parameters

No.

Parameter name

Default value

(Reference)

s

k

r

a

m

e

R

ti

n

U

e

g

n

a

r

t

u

p

n

I

93 Zone 3 MIN of linear

movement axis

0

-99999999 ~

99999999

Reference only

for SCARA axes

(axes 1 to 4)

0.001 mm Valid only when MAX > MIN. * Must be inside

the range for at least 3 msec.

* Valid for linear movement axes (axes 5 and 6

(6-axis type)) only.

(Main application version 0.15 or later)

94 Zone 3 output number for

linear movement axis

0

0 ~ 899

Reference only

for SCARA axes

(axes 1 to 4)

Physical output port or global flag (Output is

invalid if “0” is input; multiple specification is

invalid)

* Valid for linear movement axes (axes 5 and 6

(6-axis type)) only.

(Main application version 0.15 or later)

95 Zone 4 MAX of linear

movement axis

0

-99999999 ~

99999999

Reference only

for SCARA axes

(axes 1 to 4)

0.001 mm Valid only when MAX > MIN. * Must be inside

the range for at least 3 msec.

* Valid for linear movement axes (axes 5 and 6

(6-axis type)) only.

(Main application version 0.15 or later)

96 Zone 4 MIN of linear

movement axis

0

-99999999 ~

99999999

Reference only

for SCARA axes

(axes 1 to 4)

0.001 mm Valid only when MAX > MIN. * Must be inside

the range for at least 3 msec.

* Valid for linear movement axes (axes 5 and 6

(6-axis type)) only.

(Main application version 0.15 or later)

97 Zone 4 output number for

linear movement axis

0

0 ~ 899

Reference only

for SCARA axes

(axes 1 to 4)

Physical output port or global flag (Output is

invalid if “0” is input; multiple specification is

invalid)

* Valid for linear movement axes (axes 5 and 6

(6-axis type)) only.

(Main application version 0.15 or later)

98~

113

112

(For extension)

0

~

OLWL

Driver overload warning

load level ratio

100

50 ~ 100

Set the estimated motor temperature rise that

generates the overload alarm as 100%, output is

made as the overload warning to the port set in

Each Parameter No. 114 when the motor

temperature exceeded the ratio set in this parameter.

(Main application version 1.51 or later)

* To prevent motor burnout, the startup initial

temperature is assumed high considering the hot

start for the controller load ratio calculation

(Safety side). Therefore, the specification is

established not to detect the driver overload

warning till the first servo-on after specific period

of time after the controller startup in order of wrong

identification prevention when using the driver

overload warning output in purpose of malfunction

foresight monitoring.

%

Physical Output Port (Ineffective at 0, duplicated

indication invalid)

114 OLWNO

Driver overload warning

output No.

0

0 ~ 6999

(Main application Ver. 1.51 or later)

* Contact b

456

Appendix

Axis-Specific Parameters

No.

Parameter name

Default value

(Reference)

s

k

r

a

m

e

R

ti

n

U

e

g

n

a

r

t

u

p

n

I

116 (For extension)

0

~

117 PIG

0

Reference only

For adjustment by the manufacturer

118 PDG

0

Reference only

For adjustment by the manufacturer

119 PFSG

50,

50,

50,

50,

0,

0

0 ~ 100

* Change is prohibited unless instructed by the

manufacturer.

120 PFF

10

0 ~ 100

* Change is prohibited unless instructed by the

manufacturer.

121~

130

(For extension)

0

~

115

OUTDT: OLLV

0

0H ~

FFFFFFFFH

<Caution>

• The recommended output port is the fieldbus

domain.

• Confirm the fieldbus type and assign to the

domain that can ensure the simultaneity (identity)

for the specified number of bits.

* There may be a case that the simultaneity

(identity) of the data cannot be ensured

depending on the fieldbus type such as the

domain setting that exceeds the 32-bit boundary.

• When connecting to a master device available for

data simultaneity (identity) setting, make sure to

establish the setting to ensure the data

simultaneity (identity).

Bits 00 to 15: NOPIO (output port No. MIN,

BCD 4 digits input)

Bits 16 to 19: BYTPIO (number of output bites,

BCD 1 digit input)

(1: 1byte (8bits) 2: 2bytes (16bits)

4: 4bytes (32bits))

Data output setting:

Overload lebel monitor (%)

Bits 20 to 23: FPIO (format (bite order), BCD 1

digit input)

(0: Big Endian (1234ABCDh

→12h|34h|ABh|CDh, ABCDh

→ABh|CDh)

1: Middle Endian 1 (1234ABCDh

→34h|12h|CDh|ABh)

2: Middle Endian 2 (1234ABCDh

→ABh|CDh|12h|34h)

3: Little Endian (1234ABCDh

→CDh|ABh|34h|12h,

ABCDh→CDh|ABh))

Bits 24 to 27: TYPDT (output data classification,

BCD 1 digit input)

(0: Invalid (no update (no operation))

1: Test Data (Output 1234ABCDh

/ABCDh/CDh after applying FPIO)

2: OLLV (overload level monitor (%),

binary output)

* To prevent motor burnout, the

startup initial temperature is

assumed high considering the

hot start for the controller load

ratio calculation (Safety side).

Therefore, the specification is

established to output 0 for the

specific period of time after the

startup in order of wrong

identification prevention when

using the overload level monitor

output in purpose of malfunction

foresight monitoring.

On the monitoring system side,

treat the amount as a valid

value after detecting an overload

level monitor output value other

than 0 after the controller startup.

Bits 28 to 31: future expansion

(Main application Ver. 1.51 or later)

458

Summary of Contents for X-SEL PX

Page 1: ...Operation ManualSeventh Edition X SEL Controller PX QX Type Tenth Edition ...

Page 2: ......

Page 8: ......

Page 14: ......

Page 410: ...383 Appendix 386 ...

Page 452: ...425 Appendix 5 428 ...

Page 559: ......