357

Part 4 Commands

[Example 3]

If an input condition is specified, the output will turn ON upon completion of operation in

the step before the one in which the input condition is specified.

Output field

Timing

POTP

1

308

Turn ON as P1 approaches.

309

Turn ON as P2 approaches.

310

Turn ON when P3 operation is

complete.

311

Turn ON as P11 approaches.

PATH

1 3 308

312

Turn ON as P21 approaches.

20

ARC2 10

11

311

313

Turn ON as P22 approaches.

PATH

21 23 312

314

Turn ON when P23 operation is

complete.

[4] When executing continuous movement commands sequentially, the controller is calculating

approx. 100 positions ahead. This is why the steps are displayed continuously on the PC screen

or teaching-pendant screen, regardless of the actual operation. The last step in the continuous

operation section executed by continuous movement commands will wait for the applicable

operation to complete.

PATH

1 5 Actuator

operation

ARC

6 7

PATH

8

12

Step displayed on the PC software or teaching pendant

BTON

310

[5] Do not allow the output fields to duplicate in the continuous operation section executed by

continuous movement commands.

Duplicating output fields in the continuous operation section will not achieve the expected result.

The output field will turn OFF at the start of processing of each command.

POTP 1

Do not let outputs 305 through 308 to duplicate, as in

the example shown at left.

PATH

1 5 305

Continuous operation section executed by continuous

movement commands

PATH

11 15 304

The final output status of duplicate 305 through 308 is indeterminable, because it is affected by

the positioning calculation time and the relationship of durations of actual operations.

Do not create a program containing an indefinite loop of continuous movement commands using

the TAG-GOTO syntax. (It will result in an accumulation of coordinate conversion errors.)

358

Part 4 Commands

2. PATH/PSPL Commands

When executing a PATH or PSPL command, pay attention to the locus because it will change if the

acceleration/deceleration is different between points.

The locus can be fine-tuned by changing the acceleration/deceleration, but different

acceleration/deceleration settings between points will prevent smooth transition of speeds when

moving from one position to another.

If there is a large difference in deceleration/acceleration between points and the positioning distance

is small, the speed may drop. Exercise caution.

3. CIR/ARC Commands

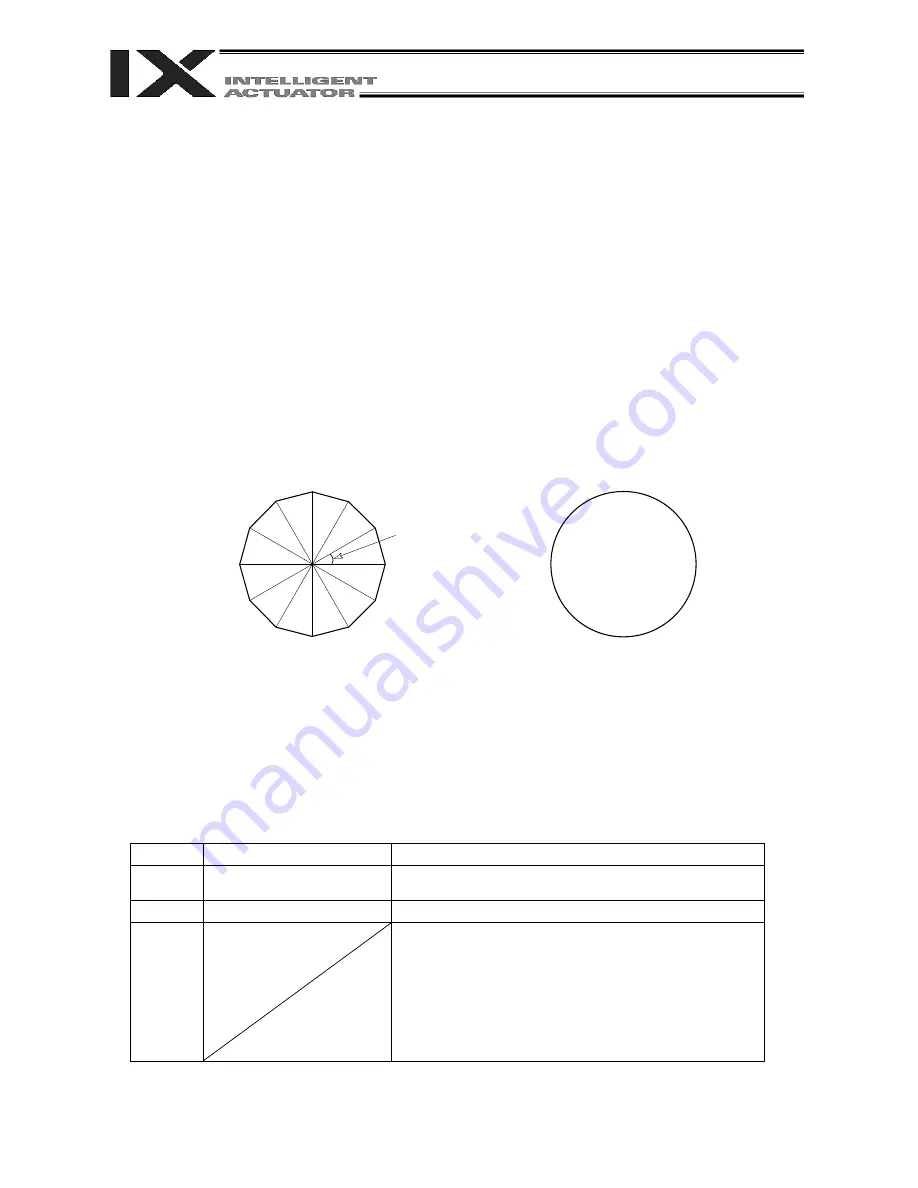

The processing by a CIR or ARC command resembles moving along a polygon with a PATH

command.

A small division angle may cause the speed to drop.

CIR2, ARC2, ARCD and ARCC commands actually perform arc interpolation.

This command is valid only on the XY plane.

4. CIR2/ARC2/ARCD/ARCC Commands

With a CIR2, ARC2, ARCD or ARCC command, the speed can be changed (only in the arc

interpolation section) by inputting a speed for the point specified in operand 1. These commands are

effective when you must lower the speed partially because the radius is small and the arc locus

cannot be maintained inside the allowable range.

The speed and acceleration will take valid values based on the following priorities:

Priority

Speed

Acceleration (deceleration)

1

Setting in the position data

specified in operand 1

Setting in the position data specified in operand 1

2

Setting by VEL command Setting by ACC (DCL) command

3

All-axis parameter No. 11, Default CP acceleration of

SCARA axis

(All-axis parameter No. 12, Default CP deceleration of

SCARA axis)

All-axis parameter No. 200, Default acceleration of

linear movement axis

(All-axis parameter No. 201, Default deceleration of

linear movement axis)

This command is valid only on the XY plane.

Division angle set by

a DEG command

CIR CIR2

361

Summary of Contents for X-SEL PX

Page 1: ...Operation ManualSeventh Edition X SEL Controller PX QX Type Tenth Edition ...

Page 2: ......

Page 8: ......

Page 14: ......

Page 410: ...383 Appendix 386 ...

Page 452: ...425 Appendix 5 428 ...

Page 559: ......