80

5 Options

RoofVent

®

twin heat units can be adapted to the requirements of the specific project with a series of

options. You will find a detailed description of all optional components in Section K 'Options' of this

handbook.

Option

Use

Hygiene design

When using the RoofVent

®

unit in applications with higher

hygiene requirements (corresponds to VDI 6022)

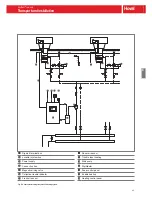

Hydraulic assembly

diverting system

To facilitate hydraulic installation

Magnetic mixing valve

For continuous regulation of the heating coil (plug-in)

Fresh air silencer

For reduction of noise from the weather louvre door

Exhaust air silencer

For reduction of noise from the exhaust air grille

Supply air silencer

For reduction of noise within the room

Extract air silencer

For reduction of noise within the room

Acoustic cowl

For reduction of noise within the room (in the Air-Injector)

Air outlet box

When using the RoofVent

®

unit in low-roofed halls

(instead of the Air-Injector)

Extract air filter in front of the

extract air grille

To protect plate heat exchanger 2 against dirt build-up

Drop eliminator

To drain condensate from plate heat exchanger 1 onto the roof

Condensate pump

To drain condensate from plate heat exchanger 2 through

waste water pipes directly below the ceiling or onto the roof

Design for injection system

For installation of the RoofVent

®

unit with a hydraulic injection

system (integrated pump control)

Table D10: Availability of options for the RoofVent

®

twin heat

RoofVent

®

twin heat

Options

Summary of Contents for RoofVent CON-9

Page 2: ......

Page 4: ...2...

Page 6: ...4...

Page 8: ...6...

Page 12: ...10 RoofVent LHW Use...

Page 40: ...38 RoofVent LKW Use...

Page 68: ...66 RoofVent twin heat Use...

Page 94: ...92 RoofVent twin cool Use...

Page 122: ...120 RoofVent twin pump Use...

Page 150: ...148...

Page 154: ...152 RoofVent condens Use...

Page 180: ...210 RoofVent LH Construction and operation...

Page 208: ...238 RoofVent LK Use...

Page 256: ...286...

Page 268: ...298...

Page 274: ...304...

Page 279: ......