78

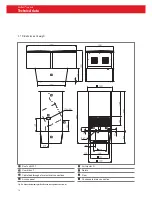

4 Design example

Design data

■

Required fresh air flow rate or air change rate

■

Hall geometry (length, width, height)

■

Design fresh air temperature

■

Desired room temperature (in the occupied area)

■

Extract air conditions

1)

■

Fabric heat losses (portion to be covered by the

RoofVent

®

units)

■

Internal heat gains (machines, lighting, etc.)

■

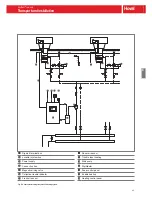

Heating medium

1)

The extract air temperature is generally higher than the temperature in the

occupied area. This is the result of unavoidable temperature stratifica-

tion in high spaces, but is reduced to a minimum with the Air-Injector.

A temperature gradient of only 0.2 K per metre height can therefore be

assumed.

Example

Fresh air flow rate ......................................25'000 m³/h

Hall geometry (L x W x H) .................... 50 x 44 x 10 m

Design fresh air temperature. .............................. -5 °C

Desired room temperature...................................18 °C

Extract air conditions ............................... 20 °C / 40 %

Fabric heat losses ........................................... 220 kW

Heat gains ......................................................... 10 kW

Heating medium ................................. LPHW 80/60 °C

Room temperature:..............................................18 °C

Temperature gradient: .................................. 10 · 0.2 K

Extract air temperature: ....................................= 20 °C

Required number of units n

req

Based on the air flow rate per unit (see Table D4), calculate

the required number of units.

n

req

= V

req

/ V

U

V

req

= required fresh air flow rate in m³/h

V

U

= air flow rate per unit in m³/h

n

req

= 25'000 / 7'100

n

req

= 3.52

Select 4 TWH-9s.

Actual fresh air flow rate V (in m³/h)

V

= n · V

U

n

= Selected number of units

V = 4 · 7'100

V = 28'400 m³/h

Effective fabric heat losses Q

Teff

(in kW)

Q

Teff

= Q

T

– Q

M

Q

T

= fabric heat losses in kW

Q

M

= internal heat loads in kW

Use the following criteria for calculation of internal heat

gains (connected loads of machines and lighting): Operating

times, diversity, direct heat output through convection, indi-

rect heat output through radiation, etc.

Q

Teff

= 220 – 10

Q

Teff

= 210 kW

Necessary output to cover fabric heat losses per unit

Q

TG

(in kW)

Q

TG

= Q

Teff

/ n

n

req

= 210 / 4

Q

Teff

= 52.5 kW

Checking the heat output

Compare the required output for coverage of the fabric

heat losses per unit with the data in Table D6. Increase the

number of units if the heat output is insufficient.

Actual output Q

TG

= 69.0 kW

Required output

= 52.5 kW

→ OK

RoofVent

®

twin heat

Design example

Summary of Contents for RoofVent CON-9

Page 2: ......

Page 4: ...2...

Page 6: ...4...

Page 8: ...6...

Page 12: ...10 RoofVent LHW Use...

Page 40: ...38 RoofVent LKW Use...

Page 68: ...66 RoofVent twin heat Use...

Page 94: ...92 RoofVent twin cool Use...

Page 122: ...120 RoofVent twin pump Use...

Page 150: ...148...

Page 154: ...152 RoofVent condens Use...

Page 180: ...210 RoofVent LH Construction and operation...

Page 208: ...238 RoofVent LK Use...

Page 256: ...286...

Page 268: ...298...

Page 274: ...304...

Page 279: ......