Figure 2.31 Connecting Control Wiring

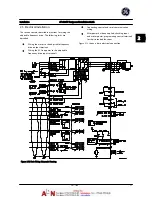

2.5.8.4 Using Shielded Control Cables

Correct shielding

The preferred method in most cases is to secure control

and serial communication cables with shielding clamps

provided at both ends to ensure best possible high

frequency cable contact.

If the ground potential between the adjustable frequency

drive and the PLC is different, electrical noise may occur

that will disturb the entire system. Solve this problem by

fitting an equalizing cable next to the control cable.

Minimum cable cross-section: 0.025 in

2

(16 mm

2)

.

Figure 2.32

1

Min. 0.025 in

2

[16 mm

2

]

2

Equalizing cable

Table 2.5

50/60 Hz ground loops

With very long control cables, ground loops may occur. To

eliminate ground loops, connect one end of the shield-to-

ground with a 100 nF capacitor (keeping leads short).

Figure 2.33

Avoid EMC noise on serial communication

This terminal is grounded via an internal RC link. Use

twisted-pair cables to reduce interference between

conductors. The recommended method is shown below:

Figure 2.34

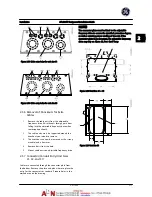

1

Min. 0.025 in

2

[16 mm

2

]

2

Equalizing cable

Table 2.6

Alternatively, the connection to terminal 61 can be

omitted:

Figure 2.35

1

Min. 0.025 in

2

[16 mm

2

]

2

Equalizing cable

Table 2.7

2.5.8.5 Control Terminal Functions

Adjustable frequency drive functions are commanded by

receiving control input signals.

•

Each terminal must be programmed for the

function it will be supporting in the parameters

associated with that terminal. See

Table 2.4

for

terminals and associated parameters.

•

It is important to confirm that the control

terminal is programmed for the correct function.

See

4 User Interface

for details on accessing

parameters and

5 About Programming

for details

on programming.

•

The default terminal programming is intended to

initiate adjustable frequency drive functioning in

a typical operational mode.

Installation

AF-600 FP Design and Installation Guide

DET-768A

2-15

2

2

Summary of Contents for AF-600 FP Series

Page 1: ...AF 600 FPTM Fan Pump Drive Design and Installation Guide GE ...

Page 17: ...Introduction AF 600 FP Design and Installation Guide 1 10 DET 768A 1 1 ...

Page 39: ...Start Up and Functional Tes AF 600 FP Design and Installation Guide 3 6 DET 768A 3 3 ...

Page 57: ...About Programming AF 600 FP Design and Installation Guide 5 14 DET 768A 5 5 ...

Page 73: ...Application Set up Examples AF 600 FP Design and Installation Guide 6 16 DET 768A 6 6 ...

Page 83: ...Installation Consideration AF 600 FP Design and Installation Guide 7 10 DET 768A 7 7 ...

Page 87: ...Status Messages AF 600 FP Design and Installation Guide 8 4 DET 768A 8 8 ...

Page 97: ...Warnings and Alarms AF 600 FP Design and Installation Guide 9 10 DET 768A 9 9 ...

Page 101: ...Basic Troubleshooting AF 600 FP Design and Installation Guide 10 4 DET 768A 10 0 ...

Page 103: ...Terminal and Applicable Wir AF 600 FP Design and Installation Guide 11 2 DET 768A 11 1 ...