3-53

3.2 Messages and Actions

3

E-2625

P2 safety thermostat (D701)

activated.

The heaters (H700 to H703) turned

off.

Shut down scanner with emergency

stop button and restart it. If problems

persist, consult your technical

representative.

Safety thermostat in the P2

processing tank is activated.

(Causes of the error message)

1. Abnormal heater system

2. Abnormal temperature sensor

system

3. Abnormal circulation system

4. Abnormal heater safety thermostat

system

E-2626

PS1/2/3 safety thermostat (D702)

activated.

The heaters (H700 to H703) turned

off.

Shut down scanner with emergency

stop button and restart it. If problems

persist, consult your technical

representative.

Safety thermostat in the PS1/2/3

processing tank is activated.

(Causes of the error message)

1. Abnormal heater system

2. Abnormal temperature sensor

system

3. Abnormal circulation system

4. Abnormal heater safety thermostat

system

E-2627

PS4 safety thermostat (D703)

activated.

The heaters (H700 to H703) turned

off.

Shut down scanner with emergency

stop button and restart it. If problems

persist, consult your technical

representative.

Safety thermostat in the PS4

processing tank is activated.

(Causes of the error message)

1. Abnormal heater system

2. Abnormal temperature sensor

system

3. Abnormal circulation system

4. Abnormal heater safety thermostat

system

E-2628

Safety thermostat in dryer section

(D760A,D760B) activated.

The heaters (H760 to 767) turned off.

Shut down scanner with emergency

stop button and restart it. If problems

persist, consult your technical

representative.

Safety thermostat in dryer section is

activated.

(Causes of the error message)

1. Abnormal dryer heater system

2. Abnormal dryer temperature

sensor system

3. Abnormal dryer fan system

4. Abnormal dryer heater safety

thermostat system

W-2629

P1 solution level (FS700) has fallen.

Temperature adjustment stopped.

Press [Help] button to see error help

(or manual). Inspect it while referring

to it.

Solution level in P1 processing tank is

lowered.

(Causes of the error message)

1. Solution leakage

2. Abnormal solution level sensor

system

3. Abnormal replenisher system

W-2630

P2 solution level (FS701) has fallen.

Temperature adjustment stopped.

Press [Help] button to see error help

(or manual). Inspect it while referring

to it.

Solution level in P2 processing tank is

lowered.

(Causes of the error message)

1. Solution leakage

2. Abnormal solution level sensor

system

3. Abnormal replenisher system

W-2631

PS1 solution level (FS702) has fallen.

Temperature adjustment stopped.

Press [Help] button to see error help

(or manual). Inspect it while referring

to it.

Solution level in PS1 processing tank

is lowered.

(Causes of the error message)

1. Solution leakage

2. Abnormal solution level sensor

system

3. Abnormal replenisher system

W-2632

PS2 solution level (FS703) has fallen.

Temperature adjustment stopped.

Press [Help] button to see error help

(or manual). Inspect it while referring

to it.

Solution level in PS2 processing tank

is lowered.

(Causes of the error message)

1. Solution leakage

2. Abnormal solution level sensor

system

3. Abnormal replenisher system

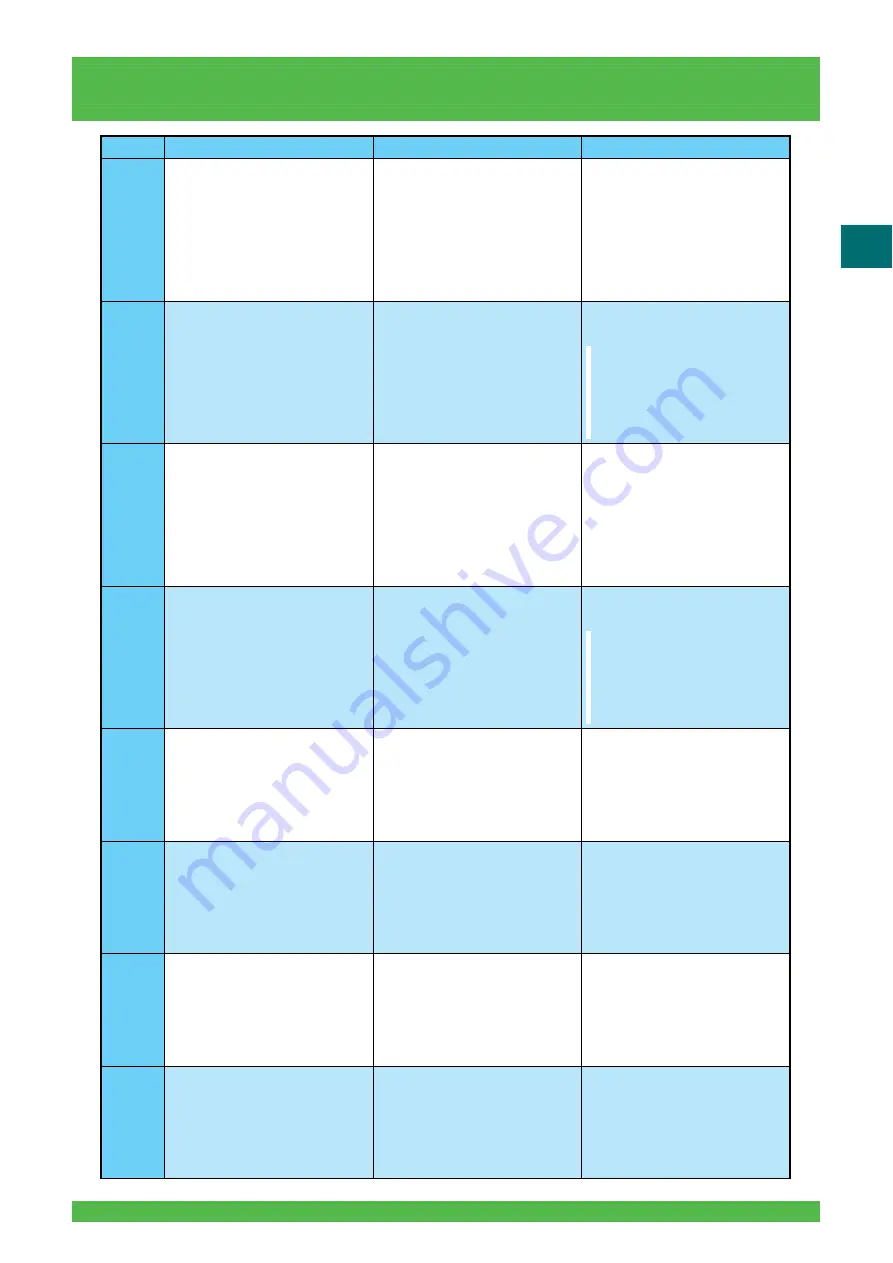

No.

Message

Factor

Actions